Energycle Recycling Machinery, as we are known, specializes in the design and manufacture of advanced plastic recycling equipment, with a particular focus on PE film washing lines. Our comprehensive washing solutions efficiently clean a wide variety of plastic films, including LLDPE/LDPE film, supermarket bags, distribution center packaging film, and PP non-woven bags like supersacs, among many others.

Our dedicated research and development center is staffed with top-tier engineers who design, test, and continually improve our recycling machinery. With over 300 employees and two decades of expertise in the plastic recycling sector, Energycle’s high-quality PP/PE film washing lines have been exported to more than 50 countries, supporting reprocessing, recycling, and washing plants worldwide.

Energycle’s manufacturing facility spans over 50,000 square meters in Jinfeng Industrial Zone, Zhangjiagang City, China. All of our high-precision machines are CE and ISO9001:2000 certified, reflecting our commitment to quality. We are dedicated to creating innovative, efficient, and long-lasting recycling machines. By using only premium materials, components, and motors from reputable Chinese, Japanese, and German manufacturers, we ensure that our machines meet the highest standards. Although this approach may raise our production costs, it also reinforces our reputation for unparalleled quality, customer service, and post-sales support, which has garnered us global recognition and a loyal customer base seeking state-of-the-art recycling solutions.

Our PE Film Recycling Washing Line

Energycle offers complete PP/PE film washing lines, incorporating equipment for size reduction, separation, washing, drying, and pelletizing. Our team of expert plastic recycling consultants provides a high level of professionalism in planning and setting up entire recycling plants based on your specifications. Some of the individual recycling machines we offer include:

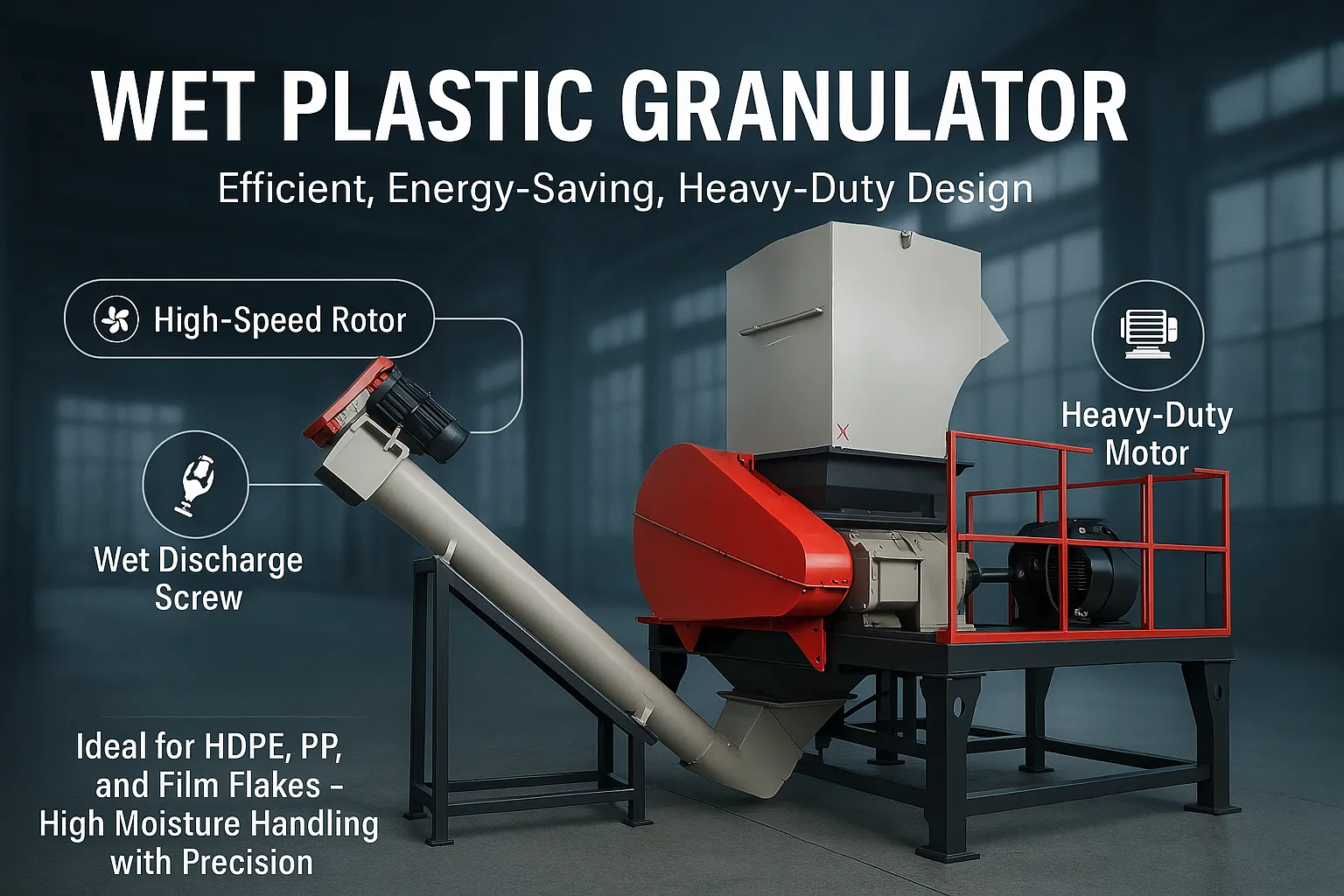

- Size Reduction: Plastic Granulator, Industrial Shredders

- Separation: “Sink/Float” Separation Tank

- Washing: High Friction Washer

- Drying: Dewatering Machine, Dewatering Screw Press, Thermal Drying System

- Pelletizing: Single-Screw Extruder, Twin-Screw Extruder

We take pride in every piece of recycling equipment we manufacture. Whether you need machinery for recycling manufacturing scrap, post-consumer plastics, or industrial plastics, we are confident that our equipment will meet your requirements. If you need specialized machinery not listed in our catalog, feel free to contact us about alternative solutions or custom project setups. Let Energycle’s experienced team support your recycling needs and help you achieve your sustainability goals.