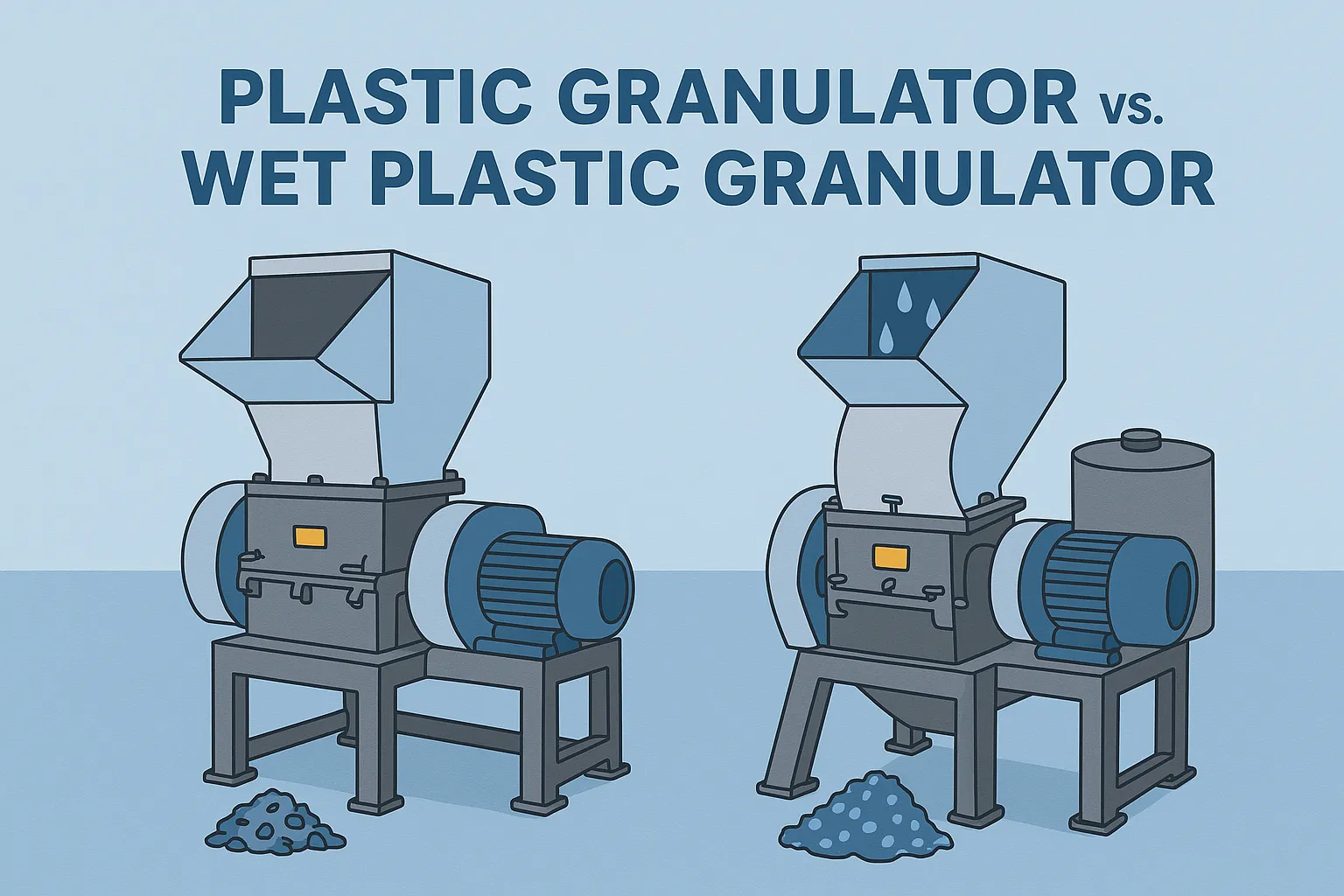

في عالم إعادة تدوير البلاستيك المتغير، تُعدّ الكفاءة والفعالية أمرًا بالغ الأهمية. ومن الخطوات الأساسية في هذه العملية تقليل النفايات البلاستيكية إلى قطع قابلة للإدارة، وهنا يأتي دور مُحبّبات البلاستيك. فبينما كانت مُحبّبات البلاستيك القياسية ركيزة أساسية في هذه الصناعة، برزت مُحبّبات البلاستيك الرطبة كبديلٍ مُقنع. تُناقش هذه المقارنة الشاملة أوجه التشابه والاختلاف الرئيسية بين هاتين التقنيتين، مُستكشفةً مزايا وعيوب كلٍّ منهما لمساعدتك على اتخاذ قرارٍ مُستنيرٍ بشأن عمليات إعادة التدوير الخاصة بك.

التشابه:

Both standard plastic granulators and wet plastic granulators serve as essential tools in plastic recycling, playing a vital role in transforming plastic waste into valuable resources. At their core, both systems employ a high-speed rotor equipped with sharp blades that interact with stationary counter blades. This cutting mechanism efficiently reduces various types of plastic, including common materials like bottles, films, and rigid plastics, into smaller, more manageable granules. Regardless of the type, these granulators are fundamental for preparing plastic for further processing, such as washing, sorting, and ultimately, remelting for new applications.

الاختلافات:

The fundamental distinction between these two types of granulators lies in the integration of water into the granulation process.

Standard (Dry) Plastic Granulators: These operate in a dry environment, meaning no water is introduced during the shredding and cutting of the plastic materials.

Wet Plastic Granulators: In contrast, wet granulators are specifically engineered to incorporate water directly into the cutting chamber as the plastic is being processed. This constant spray of water creates a unique set of benefits and considerations.

المميزات والعيوب:

حبيبات البلاستيك الرطبة:

- المميزات:

- Enhanced Pre-cleaning: The continuous water spray acts as a powerful pre-cleaning agent, effectively dislodging and washing away a significant portion of surface dirt, dust, labels, and other contaminants directly within the granulator. This can reduce the need for extensive pre-washing stages, streamlining the recycling process.

- انخفاض كبير في الاحتكاك والحرارة: Water acts as an excellent lubricant and coolant, dramatically minimizing friction between the blades and the plastic material. This results in:

- Prolonged Blade Lifespan: Reduced wear and tear on the blades means less frequent sharpening or replacement, leading to cost savings over time.

- Extended Continuous Operation: Lower heat buildup allows for longer, uninterrupted operation without the risk of overheating and potential damage.

- Superior Dust Suppression: Wet granulation effectively captures and suppresses dust particles generated during the cutting process, creating a significantly cleaner and healthier working environment within the recycling facility. This is crucial for worker safety and regulatory compliance.

- Potential for Improved Energy Efficiency: While the initial cost might be higher, the reduced friction can sometimes translate to lower energy consumption per unit of processed plastic.

- العيوب:

- Higher Initial Investment: Wet granulators typically have a higher purchase price compared to their dry counterparts due to their more complex design and the inclusion of water circulation systems.

- Additional Water Consumption and Wastewater Management: Wet granulation requires a consistent water supply and necessitates proper wastewater treatment or recycling systems to handle the water contaminated with plastic debris. This adds to the operational complexity and cost.

- Increased Maintenance Complexity: The presence of water introduces additional components like pumps, pipes, and nozzles, which require regular maintenance and may be susceptible to clogging or corrosion.

- Potentially Limited Suitability for Certain Plastic Types: Some very lightweight or water-sensitive plastics might not be ideally suited for wet granulation.

حبيبات بلاستيكية قياسية:

- المميزات:

- Lower Initial Cost: Standard granulators generally have a lower upfront purchase price, making them an attractive option for businesses with limited budgets.

- Relatively Simpler Operation and Maintenance: Without the added complexity of water systems, dry granulators tend to be easier to operate and maintain.

- تطبيق واسع النطاق: Suitable for a wide range of plastic types without the concerns associated with water interaction.

- العيوب:

- Lack of Pre-cleaning Capability: Dry granulators do not offer any inherent cleaning during the granulation process. Plastic materials often require separate pre-washing, adding an extra step to the recycling process.

- Higher Friction and Heat Generation: The absence of water lubrication leads to increased friction and heat buildup, which can:

- Shorter Blade Lifespan: Blades may require more frequent sharpening or replacement.

- Limited Continuous Operation: Overheating can be a concern, potentially requiring more frequent breaks in operation.

- Significant Dust Generation): Dry granulation can generate substantial amounts of dust, posing health risks to workers and potentially requiring dust extraction systems.

خاتمة:

The choice between a wet plastic granulator and a standard plastic granulator hinges on a careful evaluation of your specific operational needs, budget constraints, and the types of plastic you intend to process.

While standard plastic granulators offer a more budget-friendly initial investment and simpler operation, wet plastic granulators present compelling long-term advantages for many recycling facilities. The ability to perform partial pre-cleaning, significantly reduce blade wear and tear, and minimize dust generation can lead to considerable savings in maintenance, labor, and potential health and safety costs.

Ultimately, the optimal solution depends on a thorough cost-benefit analysis considering factors such as the volume and type of plastic being processed, the desired level of cleanliness of the output material, environmental regulations, and the overall efficiency goals of your recycling operation. For facilities dealing with heavily contaminated plastics or prioritizing a cleaner working environment, the benefits of a wet plastic granulator often outweigh the higher upfront cost. Conversely, for operations processing relatively clean plastics or with strict budget limitations, a standard granulator may be a suitable starting point.

[…] tool for processing plastic waste. This machine offers a unique and advantageous approach to traditional granulation by integrating water into the process. This incorporation of water not only boosts operational […]