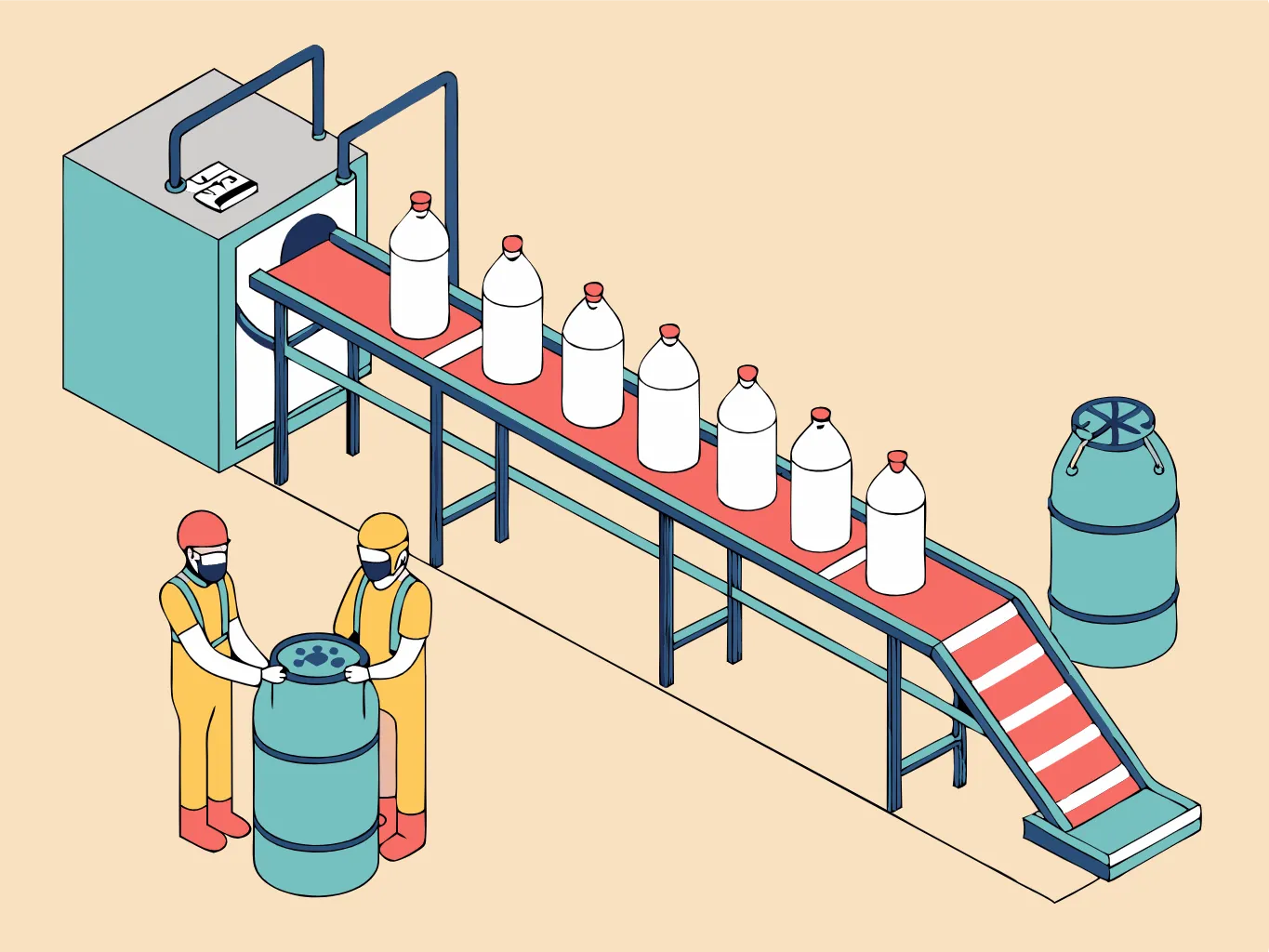

Environmental awareness is growing, making the recycling of PET bottles more critical than ever. PET washing lines are designed to handle post-consumer bottles with caps and labels, transforming them into high-purity, low-moisture PET flakes. This process ensures a more sustainable future by improving recycling efficiency.

What Is a PET Washing Line?

أ حبل غسيل PET is a high-performance recycling system that processes PET bottles through various stages. These systems are designed to handle every part of a bottle, ensuring thorough recycling from caps to labels.

Key Stages of the PET Washing Process

A PET washing line includes the following essential steps:

• Unpacking: Bottles are loosened and separated for easy processing.

• Pre-Washing: Hot water is used to remove surface contaminants.

• Label Removal: Labels are stripped from bottles to prepare them for shredding.

• Metal Detection: Any metal contaminants are identified and removed.

• Granulation/Shredding: Bottles are reduced to smaller sizes and pre-washed.

• High-Speed Friction Washing: Blades beat and spray the material for deep cleaning.

• Hot Wash Tank/Steam Washing: Glue, oil, and other residues are removed using hot water and caustic soda.

This multi-stage process ensures the production of clean, high-quality PET flakes ready for further recycling.

Output Capacities of PET Washing Lines

The output of a PET washing line depends on the equipment used and operating conditions. Typical capacities range from:

• 500-600 kg/h

• 800-1000 kg/h

• 1000-1500 kg/h

• 1500-2000 kg/h

• 2000-2500 kg/h

• 2500-3000 kg/h

These options allow recycling plants to scale operations according to their needs.

Why Choose a PET Washing Line?

PET washing lines are efficient and environmentally friendly. They utilize every part of a PET bottle, minimizing waste and promoting sustainability. These systems are ideal for businesses looking to improve recycling processes and reduce environmental impact.

How to Learn More

Interested in PET washing lines? Contact us for more information, including prices and lead times. Let’s work together to promote effective PET bottle recycling.

الأسئلة الشائعة:

• س1: What is a PET washing line?

أ1: A PET washing line is a recycling system designed to clean and process PET bottles into high-quality flakes for reuse.

• س2: What stages are included in the PET washing process?

أ2: Key stages include unpacking, pre-washing, label removal, shredding, friction washing, and hot washing.

• س3: What is the output capacity of PET washing lines?

أ3: Capacities range from 500 kg/h to 3000 kg/h, depending on the system and operations.

• س4: How do PET washing lines ensure purity?

أ4: They use advanced washing and detection systems to remove contaminants, labels, and residues.

• س5: Why are PET washing lines environmentally friendly?

أ5: They minimize waste by processing every part of the bottle, promoting recycling and reducing landfill use.

• س6: Where can I find more information on PET washing lines?

أ6: Contact us to learn more about pricing, lead times, and machine operations.

خاتمة:

PET washing lines offer a complete and efficient solution for recycling PET bottles. They produce clean, reusable flakes while minimizing waste, making them a vital tool for sustainability. If you’re looking to enhance your recycling processes, a PET washing line is a worthwhile investment. Reach out today to explore your options!

للحصول على أحدث الأسعار ومواعيد التسليم، أرسل لنا رسالة باستخدام النموذج أدناه.