Technical Specifications

| Feature | Specification |

|---|---|

| Belt Width Adaptation | 800mm |

| Suspension Height | 250mm |

| Material Thickness Adaptation | 300mm |

| Magnetic Core Size | 800*600*330mm |

| Motor Power | 3KW |

| Magnetic Core Material | Neodymium iron boron + ferrite |

| Shell + Frame | Q235, SU304 |

| Belt | Rubber belt with rubber scraper, root and circular belt thickness: 10mm |

In the world of plastic recycling, efficiency and cleanliness are paramount. Whether you're running a large-scale recycling operation or a smaller setup, the key to producing high-quality recycled plastic is ensuring that contaminants are effectively removed. Enter the high-speed friction washer—a machine specifically designed to elevate your recycling process by delivering cleaner, more refined plastic with less water waste. This article delves into the inner workings, benefits, and technical specifications of this essential piece of machinery.

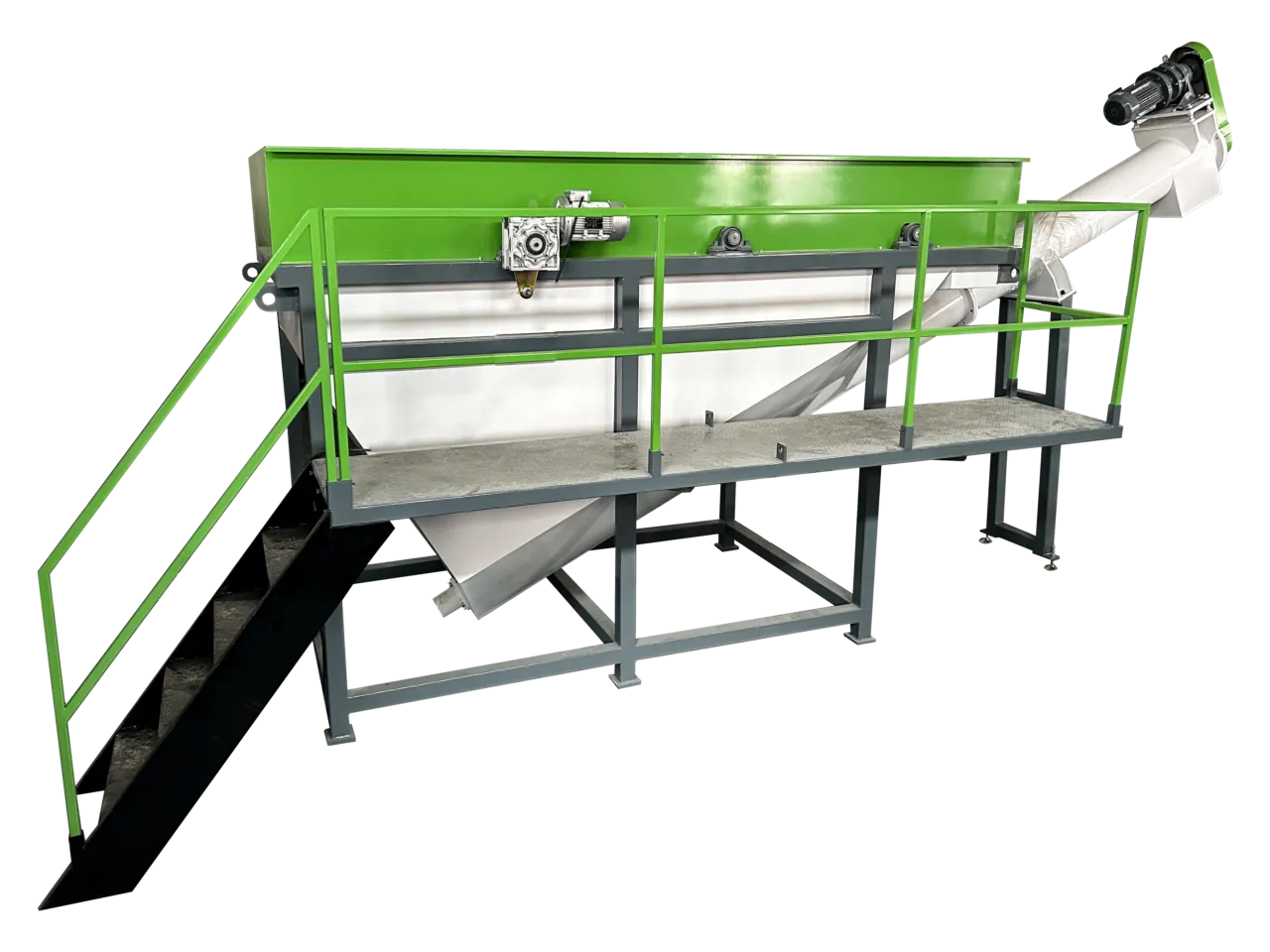

Sink-float separation tanks are essential components in plastic recycling. They play a key role in cleaning and sorting plastic materials that are denser than water, such as PET, PVC, and PS. These tanks combine washing, separation, and sediment removal in a single system, streamlining the recycling process and improving material purity. Here’s a detailed look at their functions, features, operation, and benefits.

Industrial air-cooled chillers are specialized refrigeration systems designed to cool fluids and dehumidify air in various industrial and commercial applications. They play a crucial role in maintaining optimal operating temperatures for equipment and processes, thereby enhancing productivity and preventing overheating.

Looking for a reliable way to bind your bales tightly and efficiently? Galvanized iron wire is the perfect solution for a variety of baling applications.

This durable wire is specifically designed for use with automatic horizontal balers, semi-automatic horizontal balers, and vertical balers.

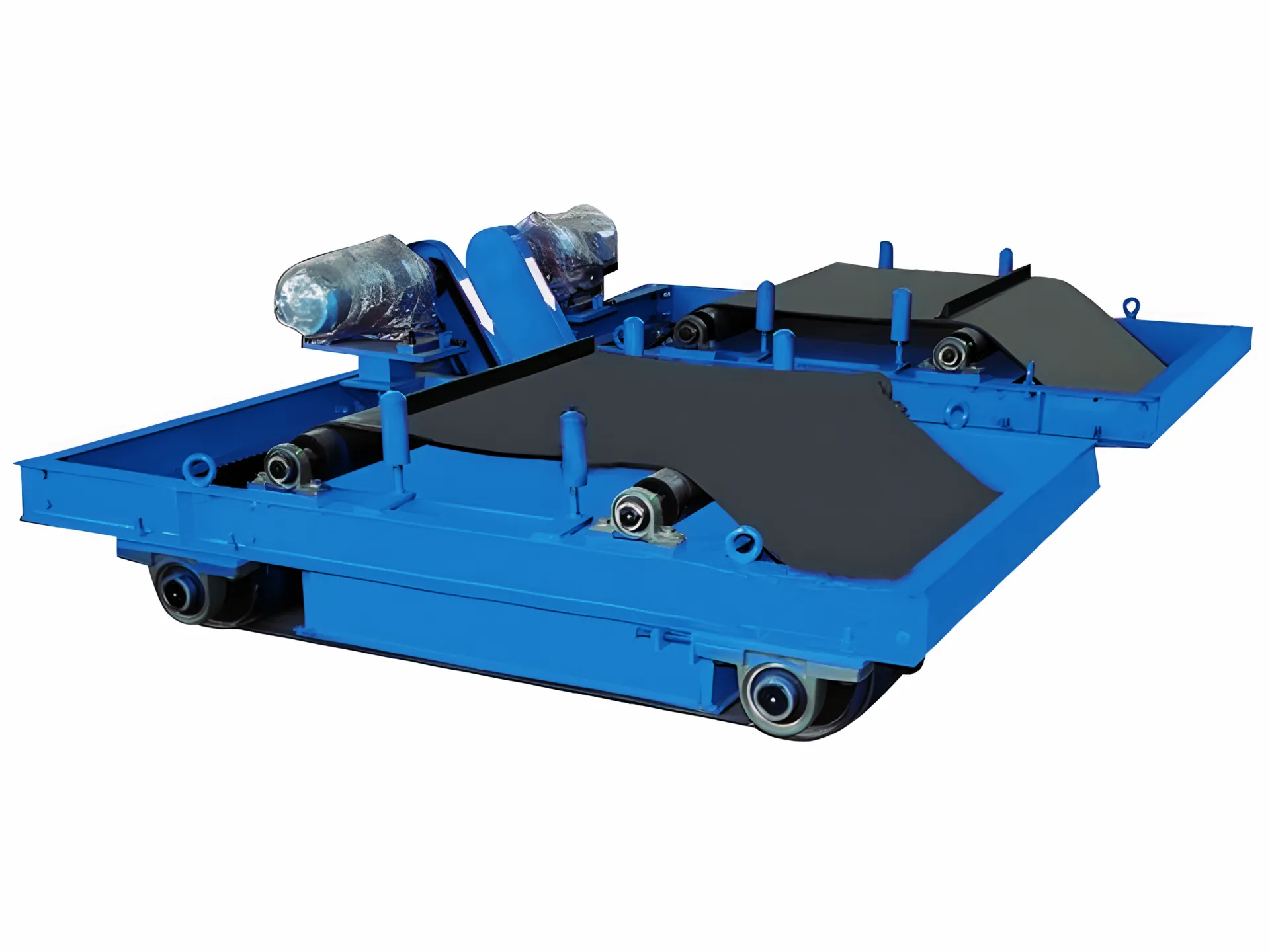

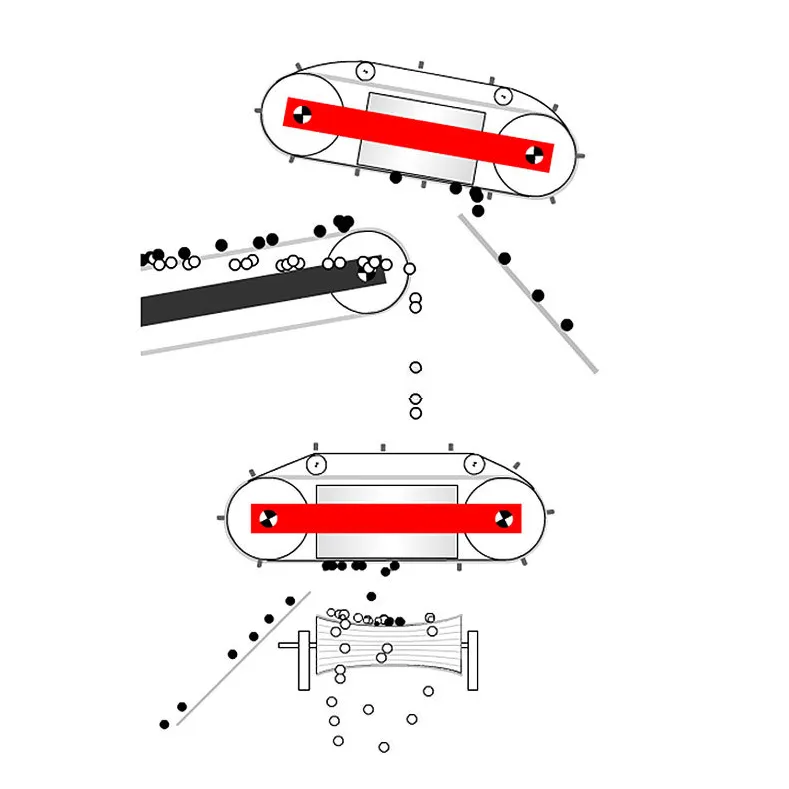

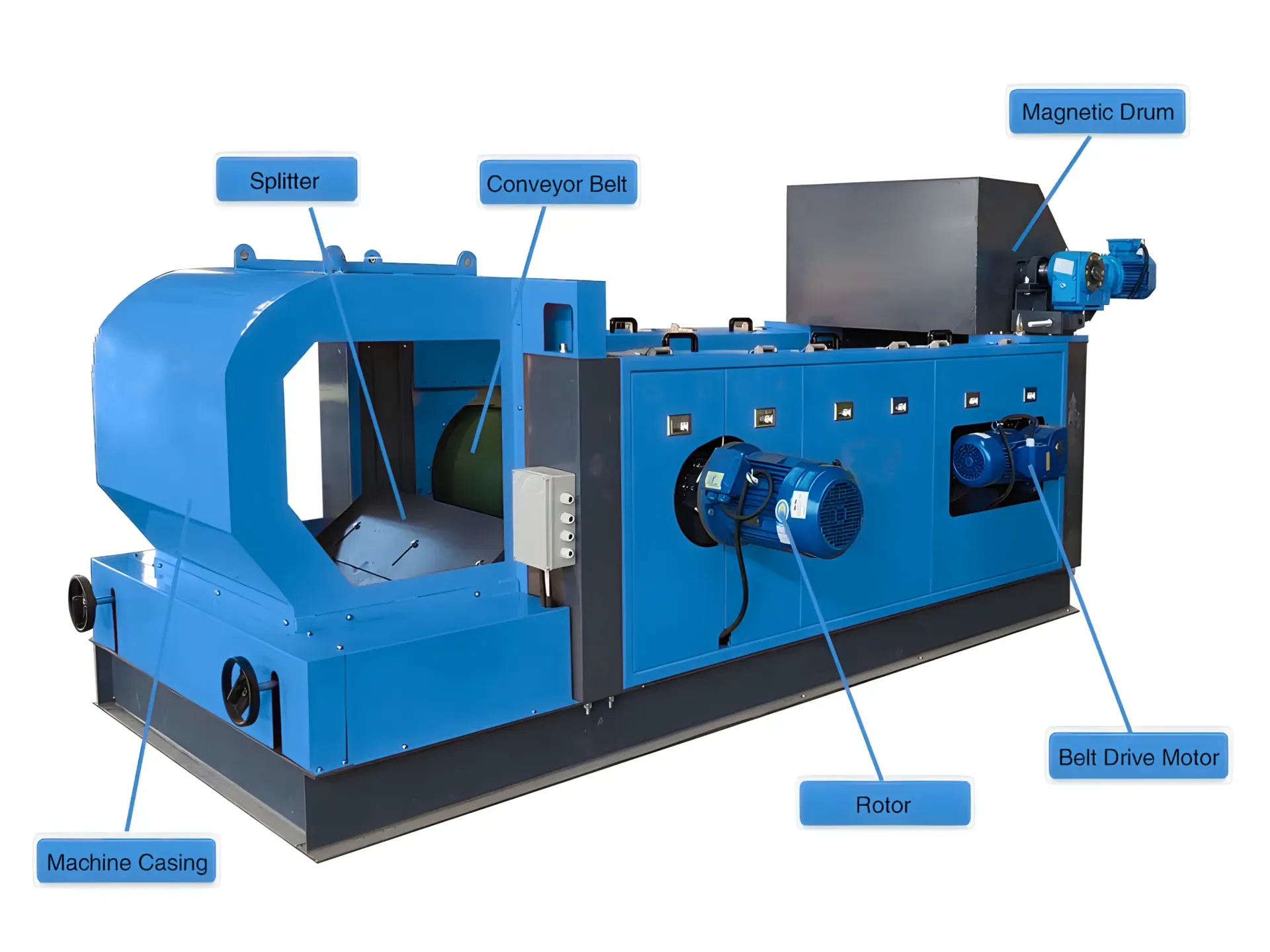

Concentric Eddy Current Separators are expertly engineered devices that excel in the seamless extraction of tiny non-ferrous particles from high-volume materials across various recycling applications. They demonstrate remarkable proficiency in classifying small fragments of aluminum waste.

A friction washer is a crucial piece of equipment in the plastic recycling process, designed to clean plastic materials (including films, sheets, and pellets) and remove moisture from them. These cylindrical machines operate through a tilted high-speed screw, demonstrating exceptional efficiency in cleaning materials by effectively removing dirt, grease, and other unwanted contaminants. Fine powders and water are separated from the grinding materials by the friction washer, which is protected by a stainless steel screen. Raw materials are fed into the machine from the bottom, undergo thorough cleaning, and are discharged from the top outlet, ensuring a highly purified final product.

Vertical Mixing and Drying Machine is a versatile piece of industrial equipment designed to perform both mixing and drying functions in various manufacturing processes. Here are some key features and applications of this type of machinery:

Heavy duty plate chain conveyors are robust and reliable systems designed to move heavy, bulky, or abrasive materials across various industries. They are known for their strength, durability, and ability to handle demanding applications.