Comprehensive Maintenance Plan: Industrial Centrifugal Dryer

1. Introduction

What is a Centrifugal Dryer?

An industrial centrifugal dryer (often called a centrifuge) is a machine used to separate liquids from solids through rapid rotation. Material is loaded into a rotating drum or basket, and the high centrifugal force pushes the liquid out through perforations or screens, leaving the drier solid material behind. They are common in industries like chemical processing, food production, pharmaceuticals, textiles, waste treatment, and mineral processing.

Importance of Regular Maintenance

Consistent and thorough maintenance is crucial for centrifugal dryers. Due to high rotational speeds and often abrasive or corrosive materials being processed, neglecting maintenance can lead to:

- Safety Hazards: Catastrophic failure due to imbalance or component wear can cause serious injury or damage.

- Reduced Efficiency: Clogged filters, worn seals, or improper balance decrease separation effectiveness and increase cycle times.

- Increased Downtime: Unexpected breakdowns halt production, leading to significant financial losses.

- Poor Product Quality: Inconsistent drying or contamination can result from poorly maintained equipment.

- Shortened Equipment Lifespan: Wear and tear accelerate without proper care, leading to premature replacement.

- Higher Operating Costs: Inefficient operation consumes more energy, and reactive repairs are typically more expensive than preventive measures.

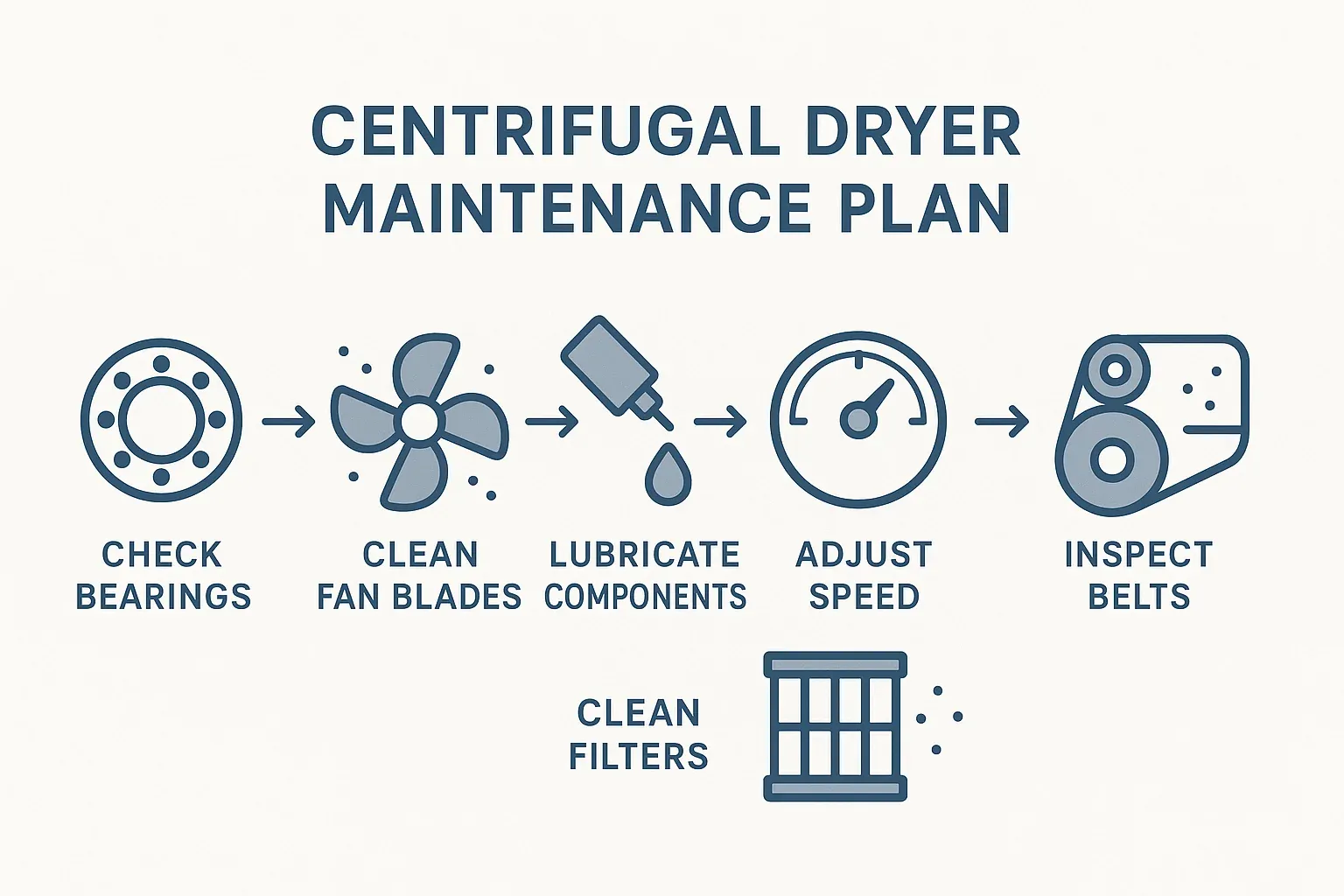

This plan outlines routine inspection, lubrication, and preventive maintenance tasks to ensure safe, reliable, and efficient operation. Always consult the specific manufacturer’s manual for your dryer model, as requirements may vary.

2. Scope

This plan covers routine operational checks and scheduled preventive maintenance tasks for a typical industrial centrifugal dryer. It includes daily, weekly, and monthly schedules, focusing on key components. Major overhauls or non-routine repairs should be performed by qualified technicians following manufacturer guidelines.

3. Responsibilities

- Operators: Perform daily checks, report abnormalities immediately, maintain basic cleanliness.

- Maintenance Technicians: Perform weekly, monthly, and scheduled PM tasks, lubrication, troubleshooting, minor repairs, and maintain detailed records.

- Maintenance Supervisor: Schedule maintenance, review logs, ensure compliance, arrange for major repairs or specialized services.

4. Scheduled Maintenance Tasks

4.1 Daily Inspections (Performed by Operator at start-up and during operation)

4.2 Weekly Inspections (Performed by Maintenance Technician)

4.3 Monthly Inspections (Performed by Maintenance Technician)

- Cleanliness: Build-up of residual material.

- Wear: Erosion or abrasion on surfaces.

- Damage: Cracks, dents, or distortion.

- Screens/Perforations: Clogging, damage, or wear.

- Balancing Weights: Ensure they are secure (if visible/accessible).

4.4 Annual / Bi-Annual / As Per Manufacturer Recommendation (Performed by Qualified Technician or Specialist)

5. Lubrication Recommendations

Proper lubrication is vital for preventing premature failure of bearings and drive components. Always refer to the manufacturer’s manual for specific lubricant types (grease NLGI grade, base oil viscosity, additives; oil ISO VG grade, type – mineral/synthetic) and frequencies.

Frequency:

- Grease Points (Bearings, etc.): Typically monthly or quarterly, depending on operating hours, speed, temperature, and environment. Some bearings may be “sealed for life” – verify this.

- Gearbox Oil: Check level weekly/monthly. Change typically annually or bi-annually, or based on oil analysis results.

- Couplings: Some require periodic greasing; others are maintenance-free. Check type.

Types of Lubricants:

- Use only the manufacturer-recommended type and grade. Mixing lubricants can be detrimental.

- Consider operating conditions (temperature, load, moisture) when selecting/confirming lubricants. Food-grade lubricants are required for food/pharma applications.

Procedures:

- Clean grease fittings (zerks) before applying grease gun.

- Apply the correct amount of grease. Over-greasing can be as harmful as under-greasing (can cause overheating, damage seals). Follow manufacturer guidelines (e.g., number of pumps, volume, or until slight purge is seen from relief port).

- When changing oil, drain the old oil completely while warm, flush if necessary/recommended, and refill to the correct level with new, clean oil.

- Dispose of used lubricants responsibly according to environmental regulations.

- Record lubrication details (date, type, amount, technician) in the maintenance log.

6. Troubleshooting Common Issues

| Symptom | Possible Cause(s) | Corrective Action(s) |

|---|---|---|

| Excessive Vibration |

|

|

| Overheating (Motor) |

|

|

| Unusual Noise (Grinding, Rattling, Knocking) |

|

|

| Leaks (Product) |

|

|

| Leaks (Lubricant) |

|

|

| Reduced Efficiency (Wet Product) |

|

|

7. Safety Precautions During Maintenance

Safety is paramount when working on centrifugal dryers.

- LOCKOUT/TAGOUT (LOTO): ALWAYS de-energize and lock out the main electrical disconnect before performing any maintenance. Follow established site LOTO procedures.

- Personal Protective Equipment (PPE): Use appropriate PPE, including safety glasses, sturdy gloves, hearing protection (if noise levels are high), steel-toed boots, and possibly respirators depending on the materials processed.

- Cool Down: Allow hot components (motor, bearings, gearbox) to cool before touching them.

- Machine Stability: Ensure the machine is stable and cannot move or tip.

- Confined Space: If entering the drum/basket is required, follow all site-specific confined space entry procedures (permits, atmospheric monitoring, attendant).

- Rotating Parts: Be aware that even after power is off, some parts might coast. Ensure all rotation has completely stopped before accessing moving parts. Never reach into moving machinery.

- Electrical Hazards: Only qualified electricians should work on electrical components or within control panels.

- Manual Handling: Use proper lifting techniques or mechanical aids when handling heavy components (motors, drum parts).

- Manufacturer Warnings: Heed all safety warnings and instructions provided in the manufacturer’s manual.

- No Bypassing Safeties: Never disable or bypass safety interlocks or guards.

8. Record Keeping and Maintenance Log

Maintaining accurate records is essential for an effective maintenance program.

Importance:

- Tracks maintenance history and component life.

- Helps identify recurring problems and trends.

- Provides data for scheduling future PM tasks effectively.

- Supports troubleshooting efforts.

- Ensures compliance with safety and operational regulations.

- Can be vital for warranty claims.

What to Record:

- Date of service

- Machine identification (ID number, location)

- Type of maintenance (daily check, weekly PM, monthly PM, repair, lubrication)

- Description of tasks performed

- Any measurements taken (vibration levels, temperatures)

- Parts replaced (part number, quantity)

- Lubricant used (type, quantity)

- Condition found (e.g., “Belt worn,” “Bearing noisy,” “Filter clogged”)

- Corrective actions taken

- Technician’s name or initials

- Downtime duration (if applicable)

Method:

Use a dedicated logbook kept near the machine, a centralized maintenance database, or a Computerized Maintenance Management System (CMMS).

9. Benefits of Preventive Maintenance (PM)

Disclaimer: This plan provides general guidelines. Always prioritize safety and consult the specific operational and maintenance manual provided by the manufacturer of your centrifugal dryer. Adapt this plan based on your specific equipment, operating conditions, processed materials, and regulatory requirements. Work should only be performed by trained and qualified personnel.