Understanding Cutter-Compactors and Shredders in Plastic Recycling

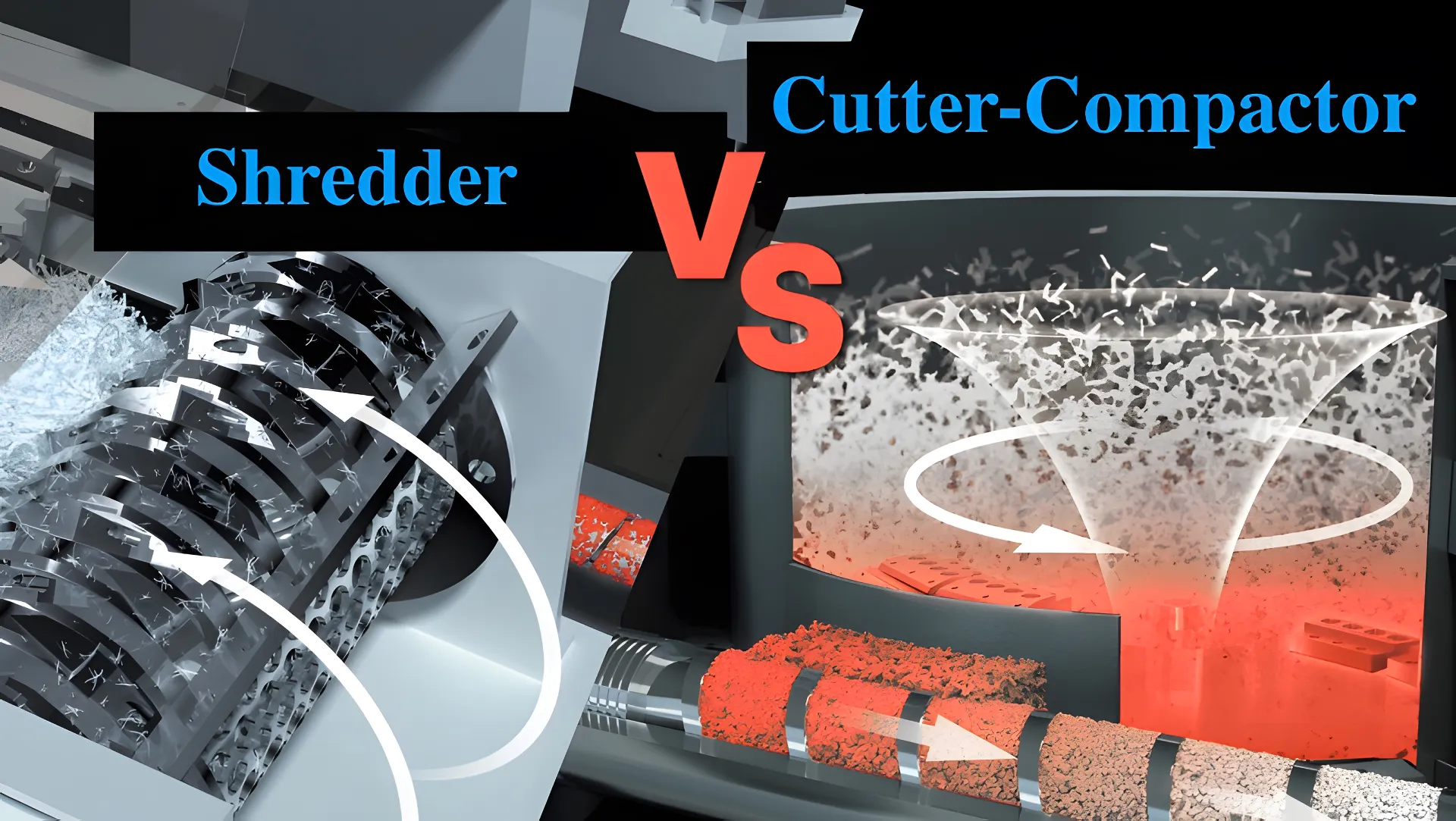

When selecting equipment for plastic recycling, it’s important to understand the differences between cutter-compactors and shredders. These two machines play distinct roles in preparing plastic waste for extrusion and pelletizing. This article explores the key differences in their functions, applications, and material suitability.

Cutter-Compactor Functionality

A cutter-compactor is designed to reduce the size of and densify plastic waste in preparation for the extrusion process. The machine typically features two types of blades:

- Stationary Blades: These blades are fixed to the bottom of the compactor and can be easily replaced. They act as a cutting surface.

- Rotary Blades: These blades rotate, similar to a blender, to mix and cut the plastic material.

The combination of these blade actions results in a clean, gentle cut of the plastic. The cutter-compactor’s main purpose is to homogenize plastic waste, ensuring it can be fed consistently into an extruder for uniform pellet production. This makes it ideal for materials like polyethylene (PE)—including HDPE, LDPE, and LLDPE—and polypropylene (PP). The machine’s ability to process these plastics without pre-cutting reduces energy use and space requirements for the recycling line.

Shredder Functionality

A shredder is built for heavy-duty size reduction, handling both dense and lightweight plastics. It uses a hydraulic plate to push bulky materials toward a rotating rotor equipped with blades. These powerful blades effectively cut and crush plastic waste into small pieces.

The shredder’s goal is to reduce the size of plastics with minimal degradation, preparing them for further processing like extrusion. Unlike the cutter-compactor, the shredder lacks a mixing function and focuses solely on shredding. Once shredded, the material is fed directly into the extruder. Shredders are particularly effective with hard plastics, thick materials, and large pieces, including lumps.

Key Differences Between Cutter-Compactor and Shredder

| Feature | Cutter-Compactor | Shredder |

|---|---|---|

| Primary Action | Cuts and compacts material. | Shreds material. |

| Blade Action | Gentle cutting and mixing with stationary and rotary blades. | Crushes and cuts with heavy-duty rotating blades. |

| Material Suitability | Ideal for flexible PE and PP films and packaging. | Handles thick, bulky, hard plastics. |

| Feeding to Extruder | Prepares material for consistent feeding. | Feeds material directly without pre-conditioning. |

| Space Requirement | Compact, integrated system. | Larger footprint, can be integrated into systems. |

Integrated Systems

Cutter-compactors and shredders are often part of larger recycling systems. Cutter-compactor systems are ideal for processing flexible packaging materials. These systems combine cutting, extrusion, and pelletizing in one compact line, eliminating the need for a separate crusher and reducing the risk of inconsistent feeding. Shredder systems are designed to handle bulky waste materials, feeding them directly into the extruder to maintain consistent throughput and high-quality recycled output.

Conclusion

Choosing between a cutter-compactor and a shredder depends on the type of plastic waste being processed. Cutter-compactors are perfect for flexible materials and focus on homogenizing the waste, while shredders are better for handling large, tough plastics and reducing their size. Selecting the right equipment is crucial for efficient and effective plastic recycling. For expert guidance on the best machine for your operation, consider consulting a recycling specialist.

FAQs:

- Q1: What is the difference between a cutter-compactor and a shredder in plastic recycling?

- A1: Cutter-compactors reduce and densify plastic waste for extrusion, while shredders focus on heavy-duty size reduction, particularly for tough materials.

- Q2: Can a shredder handle flexible plastics like polyethylene?

- A2: No, shredders are better suited for hard plastics and large pieces. Cutter-compactors are ideal for flexible plastics like polyethylene and polypropylene.

- Q3: How does a cutter-compactor improve the recycling process?

- A3: It ensures consistent material feeding to the extruder by gently cutting and homogenizing the plastic waste, reducing energy consumption.

- Q4: What types of plastics are best suited for shredders?

- A4: Shredders work best with thick, bulky, and hard plastics, such as large lumps and industrial waste.

- Q5: Do cutter-compactors require pre-cutting of materials?

- A5: No, cutter-compactors can process plastics without the need for pre-cutting, saving both space and energy.

- Q6: Can both cutter-compactors and shredders be part of the same recycling system?

- A6: Yes, both can be integrated into recycling systems, with cutter-compactors handling flexible materials and shredders processing bulky waste.