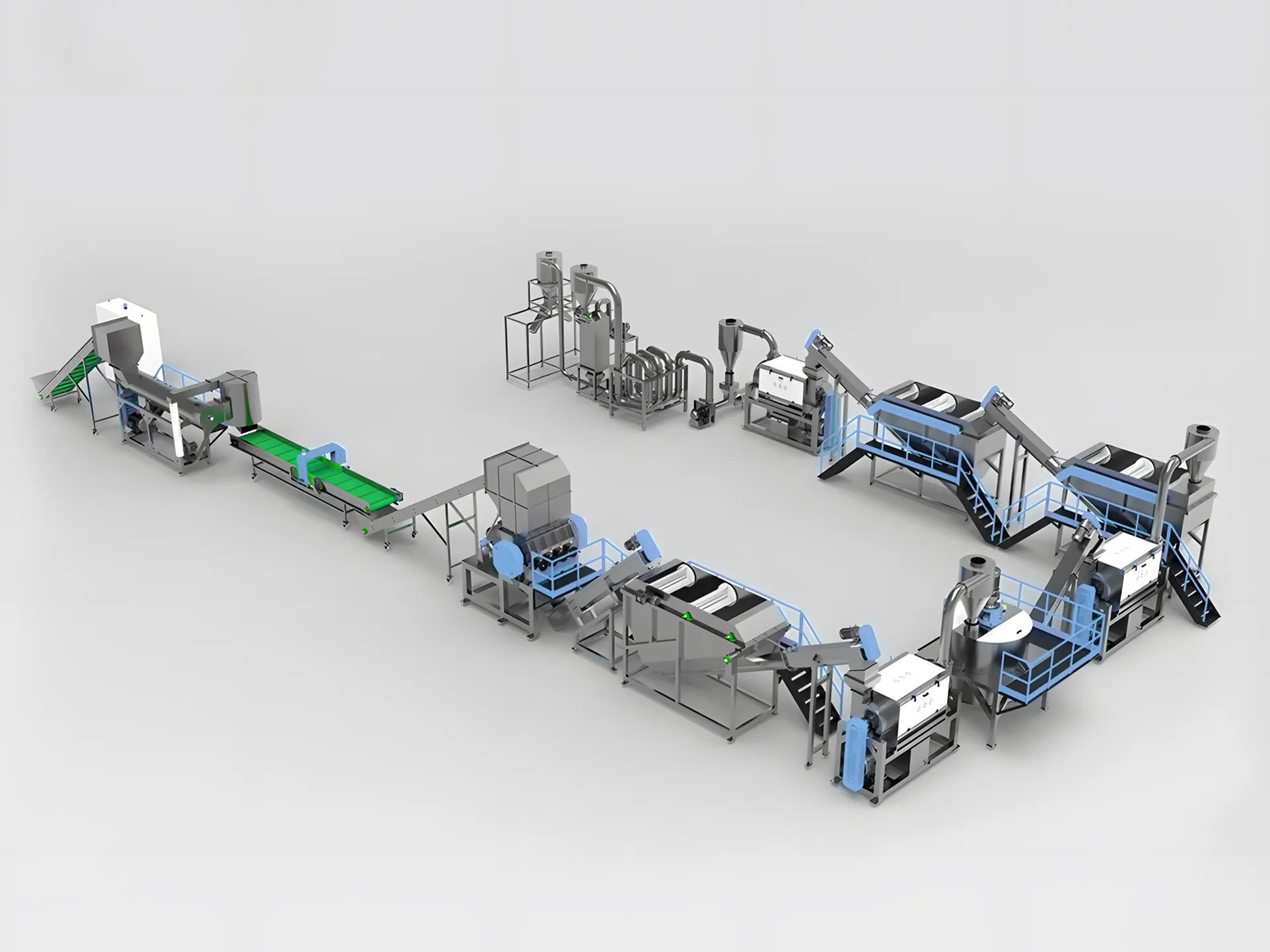

The need for efficient and reliable plastic recycling solutions has never been greater. Our comprehensive PET bottle washing line provides a turnkey solution for businesses aiming to enhance their plastic bottle recycling operations. This fully automated system transforms baled PET bottles into high-quality, contaminant-free PET flakes, ideal for manufacturing new PET products or producing polyester staple fibre.

Efficient Recycling Workflow

Our PET bottle washing line is composed of multiple interconnected recycling machines, each playing a critical role in achieving optimal recycling results.

- Deballer maskine: The process begins with the debaler, which breaks down compacted bales of PET bottles, creating a free-flowing stream for further processing.

- Trommel: The trommel is a slow-rotating tunnel lined with small holes that efficiently separates small contaminants from the PET bottles.

- Wet Granulator/Crusher: The bottles are cut into small flakes, while an air classifier then removes lighter materials such as paper and plastic labels.

- Sink/Float Separation Tank: This system separates materials based on buoyancy, allowing PET plastic to sink while lighter contaminants such as film or PP/PE plastic float.

- Varmt vaskesystem: The hot washer dissolves glue residues and leftover food or beverages, while the friction washer effectively removes any remaining dirt.

- Dewatering and Thermal Dryer: These machines work together to eliminate residual moisture, ensuring the PET flakes are clean and dry before storage.

- Produkt Silo: The clean, dry PET flakes are then stored, ready for reuse. Additionally, we offer optional pelletizers/extruders to convert the flakes into plastic pellets for further applications.

Producing High-Quality PET Flakes

Our PET washing line ensures that the final product meets the highest quality standards, delivering PET flakes with less than 1-2% moisture content, low impurity levels, and minimal PVC, metal, or PE/PP contamination. The particle size of the flakes is kept within a precise range of 14-16 mm, making them suitable for a wide range of applications.

Key Advantages of Our Recycling Line

- Comprehensive Contaminant Removal: With a combination of manual and automated sorting, our recycling line effectively removes labels, metals, and other impurities, ensuring clean and pure PET flakes.

- High-Performance Washing: Equipped with advanced washing systems, including hot washers, flotation tanks, and friction brushes, the line provides thorough cleaning for exceptional flake quality.

- Optical Sorting Precision: Our line integrates both optical and manual sorting systems to achieve consistent quality by sorting flakes by type and color.

- Consistent Moisture Control: With the integrated dewatering and thermal drying systems, the moisture content of the final PET flakes is consistently kept below 1-2%, making them ready for further processing.

Step-by-Step Process Overview

| Step | Beskrivelse |

|---|---|

| De-baling | Separating PET bottles from baled packages |

| Metal Removal | Extracting metals using magnets or electromagnets |

| Label Removal | Removing labels chemically or mechanically |

| Bottle Pre-washing | Initial wash before main washing |

| Optical Sorting | Sorting bottles by type and color with optical sensors |

| Manual Sorting | Further manual sorting by color, type, and material |

| Knusende | Shredding bottles into small pieces |

| Dust Removal | Removing dust from shredded PET pieces |

| Flotation Hot Washing | Cleaning flakes using hot water in a flotation tank |

| Friction Washing | Removing remaining contaminants with brushes |

| Skylning | Rinsing flakes to eliminate any residual cleaning agents |

| Tørring | Using air or spinning processes to dry the PET flakes |

| Optical Flakes Sorting | Sorting flakes by type and color with sensors |

| Blending | Blending different types and colors of PET flakes |

| Online Inspection | Ensuring quality through online inspection |

| Packing | Packaging PET flakes in suitable containers |

PS:Equipment configuration and the process will be optimized accordingl to raw materials.

Invest in Sustainable Recycling Solutions

Our PET bottle washing line delivers a comprehensive and automated recycling solution that allows businesses to efficiently turn post-consumer PET bottles into a valuable resource. With consistent product quality and optimized energy consumption, our system ensures a sustainable recycling process while maximizing profitability for your operations.

FORESPØRGSEL

Garanti

Alle genbrugsmaskiner leveres med 1 års begrænset garanti.

For at få de seneste priser og leveringstider, send os en besked ved at bruge formularen nedenfor.