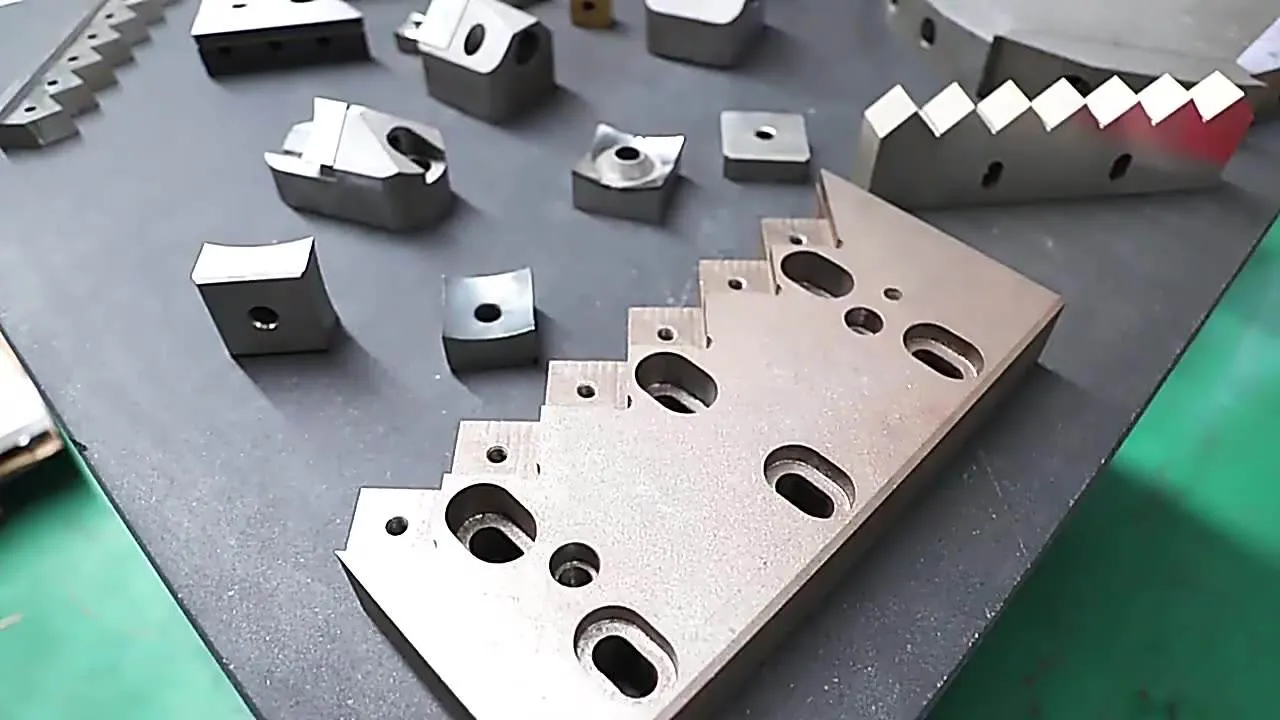

In the realm of plastic recycling, crushers and shredders are essential for transforming waste materials into smaller, manageable pieces suitable for further processing. The effectiveness of these machines largely depends on the quality and suitability of their cutting tools—blades that must withstand diverse plastic types and varying degrees of abrasion.

Importance of Blade Material Selection

Selecting the appropriate blade material is crucial for optimizing performance and extending the lifespan of crushers and shredders. Key properties to consider include:

- Hardness: Determines the blade’s ability to cut through materials.

- Toughness: Indicates resistance to chipping or breaking under impact.

- Wear Resistance: Reflects the blade’s durability against abrasive materials.

A well-chosen blade material enhances cutting efficiency, reduces downtime, and lowers maintenance costs.

Common Blade Materials and Their Applications

- SKD-11 (D2):

- Composition: High-carbon, high-chromium steel.

- Properties: Offers high hardness and wear resistance.

- Ansøgninger: Suitable for cutting hard plastics like ABS and nylon, where wear resistance is critical.

- D2:

- Composition: Similar to SKD-11, with high carbon and chromium content.

- Properties: Excels in wear resistance.

- Ansøgninger: Ideal for processing abrasive materials, including plastics mixed with glass fibers.

- DC53:

- Composition: High-carbon steel with added elements for increased toughness.

- Properties: Balances wear resistance and toughness.

- Ansøgninger: Versatile; suitable for materials like PVC and rubber, where both wear resistance and toughness are necessary.

- 55SiCr:

- Composition: Silicon-chromium spring steel.

- Properties: Provides good elasticity and impact resistance.

- Ansøgninger: Best for soft plastics and applications requiring shock absorption.

Factors to Consider When Choosing Blade Material

- Type of Plastic: Harder plastics require materials with higher hardness and wear resistance.

- Presence of Abrasives: Materials mixed with abrasive substances like glass fibers necessitate blades with superior wear resistance.

- Machine Operating Conditions: Continuous operation and high-impact scenarios benefit from materials with high toughness and thermal stability.

- Budget Considerations: While higher-quality materials may have a higher upfront cost, they can offer better durability and performance, potentially reducing long-term expenses.

By carefully assessing these factors and selecting the appropriate blade material, operators can significantly enhance the efficiency and longevity of their plastic recycling equipment, ensuring optimal performance and cost-effectiveness.

FORESPØRGSEL

For at få de seneste priser og leveringstider, send os en besked ved at bruge formularen nedenfor.