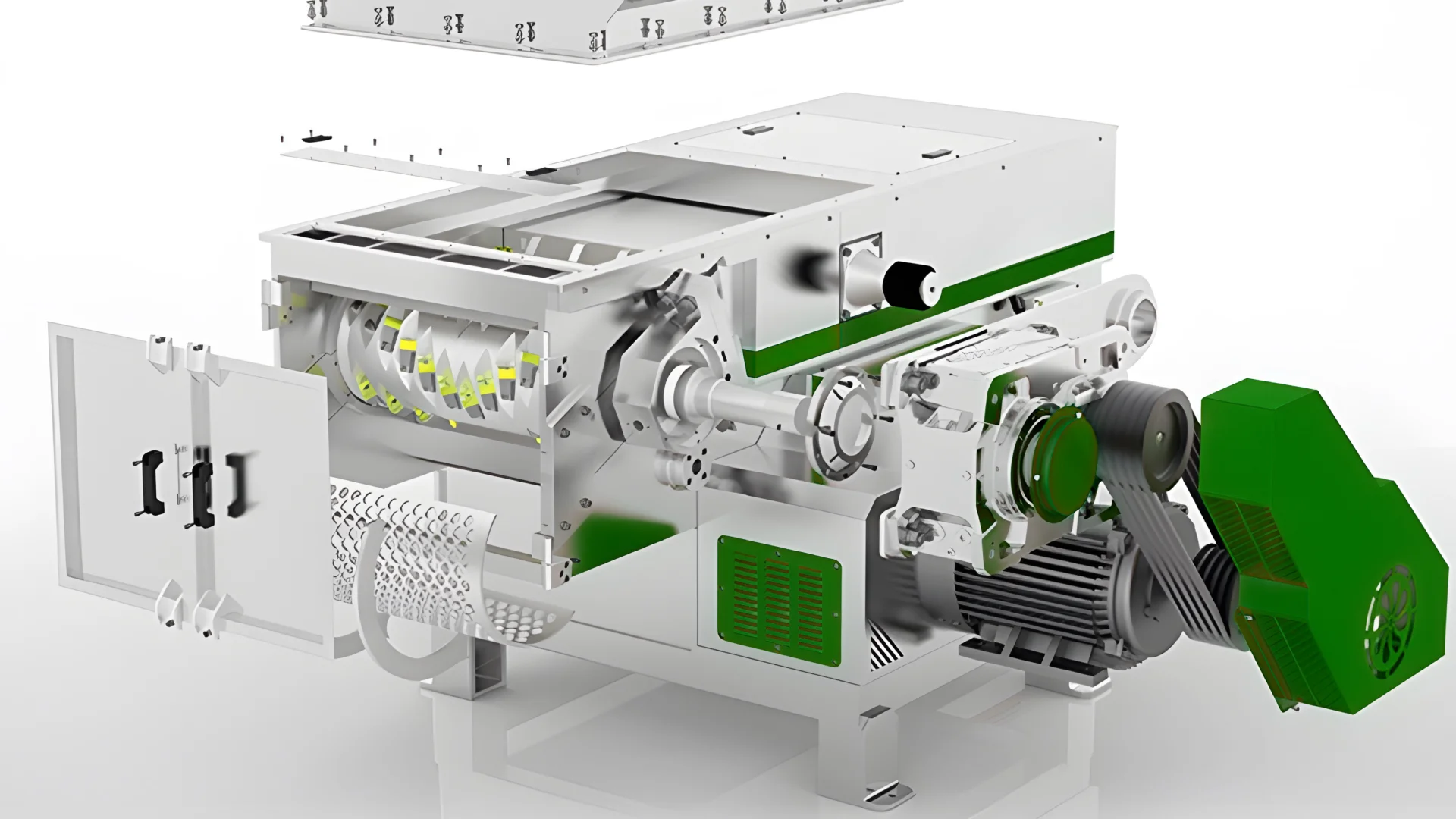

E-Scrap Shredder: Sikring af dine fortrolige oplysninger

I nutidens digitale tidsalder er elektroniske enheder en integreret del af vores daglige liv, men efterhånden som de når slutningen af deres brugbarhed, bliver de ofte en sikkerhedsfaktor...