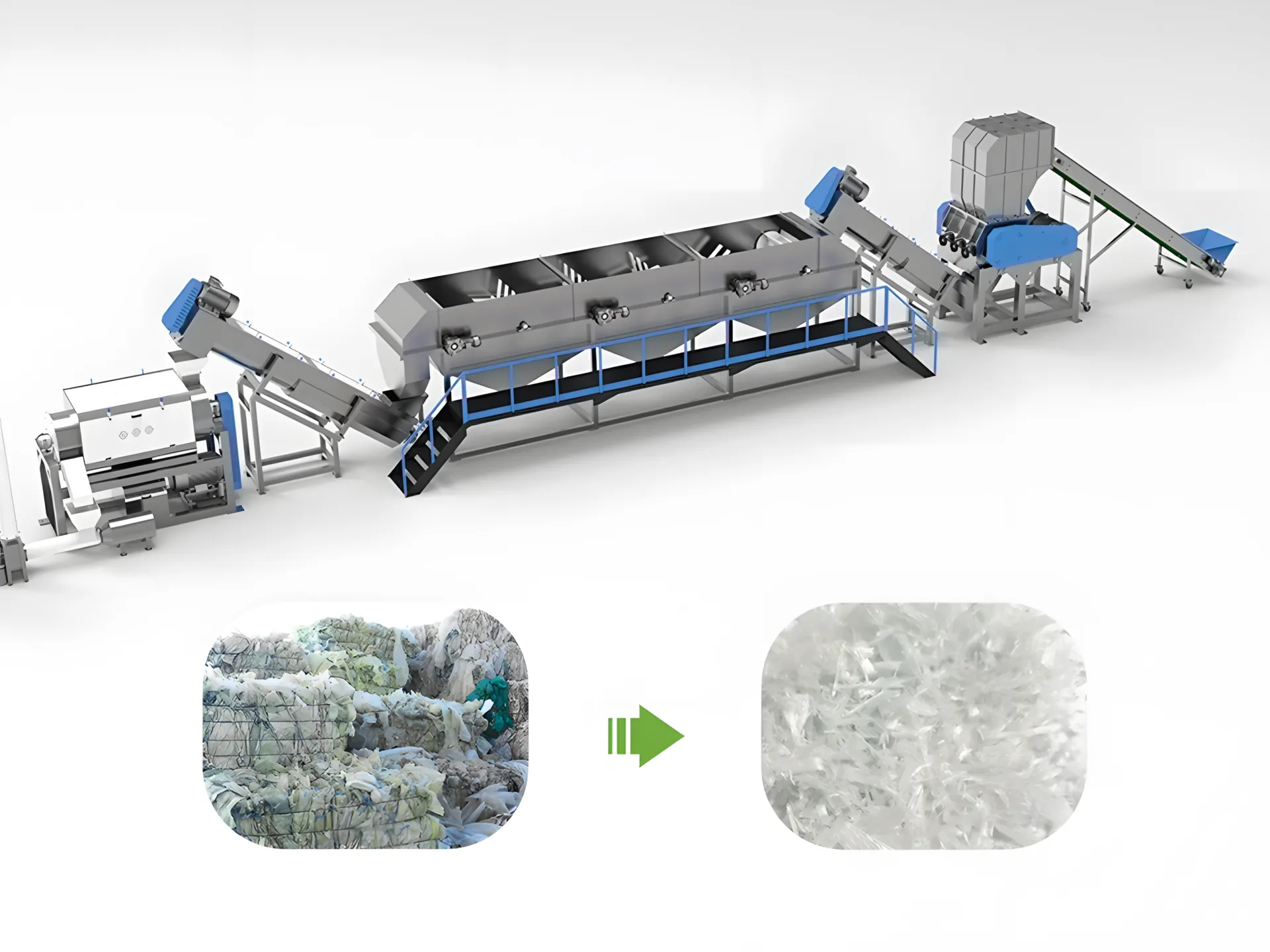

Our company specializes in delivering efficient and sustainable solutions for plastic film recycling, addressing the growing demand for plastic pellets while safeguarding the environment. Our comprehensive plastic film washing line is capable of processing polypropylene (PP), polyethylene (PE), and various other types of plastic films. Utilizing advanced technology, our fully automated washing and pelletizing line is designed with strategically positioned machines to ensure maximum efficiency and minimal waste.

In addition to our standard Plastic Film Recycling Washing Line, which offers input capacities ranging from 500 kg/h to 3,000 kg/h, we also provide customized systems for clients with larger-scale recycling needs. These tailored setups incorporate additional machinery and increased capacity to meet each client’s specific requirements.

Our turnkey solution efficiently transforms loose or baled plastic film into pellets while reducing the carbon footprint of plastic waste. By recycling rather than sending materials to landfills, we contribute to a healthier environment and a more sustainable future.

We take pride in our commitment to sustainability and our superior customer service. Our experienced team is always ready to help you find the ideal solution for your plastic film recycling needs. Contact us today to learn more about our turnkey system and discover how it can help you make a positive environmental impact while maintaining profitability.

Main Technical Parameters

We offer free solution design services, with our experts designing the most suitable plastic film cleaning line based on your specific needs and requirements. Contact us today for more information and to discuss your project.

Arbejdsprincip

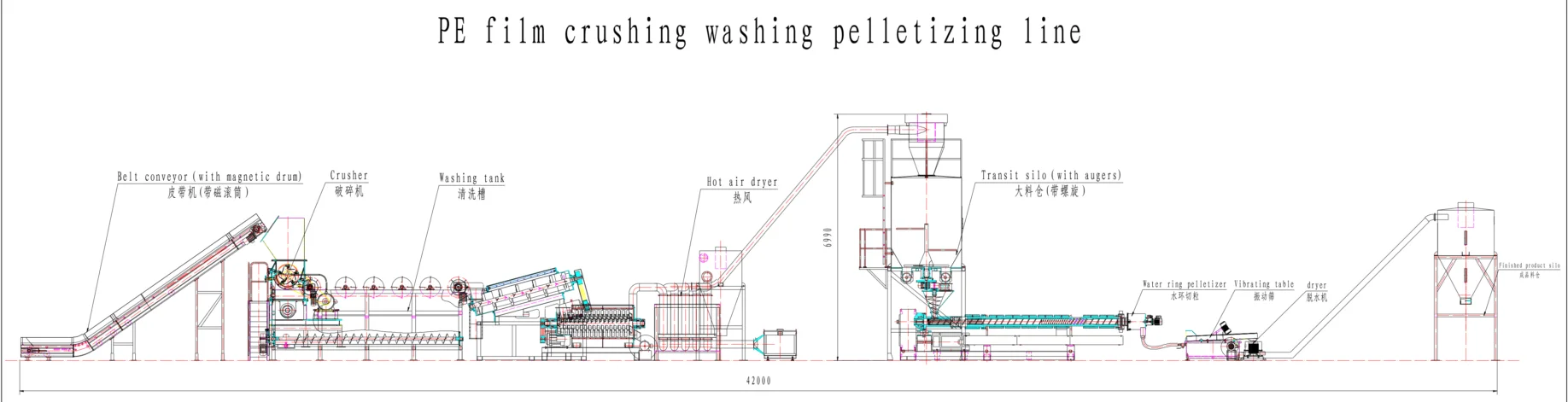

The plastic film washing line is operated via a central electric control panel and cabinet, with each machine connected by conveyors for smooth and efficient operation.

- Plastkværnmaskine: Plastic film, prone to tangling, is first cut into smaller pieces (1-5 inches) by a shredder, preventing clogging in subsequent processes.

- Plastgranulator: The granulator further reduces the plastic pieces to 10-20 mm. During this wet granulation process, water is introduced to pre-treat and partially clean the plastic before proceeding.

- Friktionsskive: Operating at nearly 1,000 rotations per minute, the friction washer effectively removes contaminants through high-speed friction. It also breaks down paper and cardboard into fibers for easy removal. Some systems may include a second friction washer for enhanced cleanliness.

- Sink-Float Separationstank: By using water as a medium, this tank separates lighter plastic films, such as PP and PE, from heavier contaminants like sand, glass, and metals, which sink to the bottom for removal.

- Centrifugal Dewatering Machine: As the initial step in the drying process, this machine uses centrifugal force to remove most of the water before thermal drying, optimizing energy efficiency and reducing long-term operational costs.

- Screw Press Dewatering Machine: An optional addition, the screw press dewatering machine utilizes high pressure to squeeze water out of the plastic film. It can replace both the centrifugal dewatering machine and thermal dryers for increased efficiency.

- Thermal Dryer & Cyclone Separator: The plastic film passes through a series of heated stainless-steel tubes, where any remaining moisture is evaporated. The cyclone separator mixes the film with cold air to prepare it for storage while also removing dust and fines.

- Produkt Silo: The clean, dry plastic film is stored in the product silo for further processing.

- Plast pelletiseringsmaskine: In the final stage, the clean plastic film is processed into plastic pellets using our specialized water ring pelletizer system, producing high-quality round pellets ready for use in manufacturing.

FORESPØRGSEL

Garanti

Alle genbrugsmaskiner leveres med 1 års begrænset garanti.

For at få de seneste priser og leveringstider, send os en besked ved at bruge formularen nedenfor.