Arbejdsprincip

1. Fodring og knusning

2. Hydraulisk kompression

- De knuste skumstykker overføres til et kompressionskammer.

- Et hydraulisk system påfører et betydeligt tryk for at komprimere skummet, hvilket effektivt reducerer dets volumen med op til 50:1.

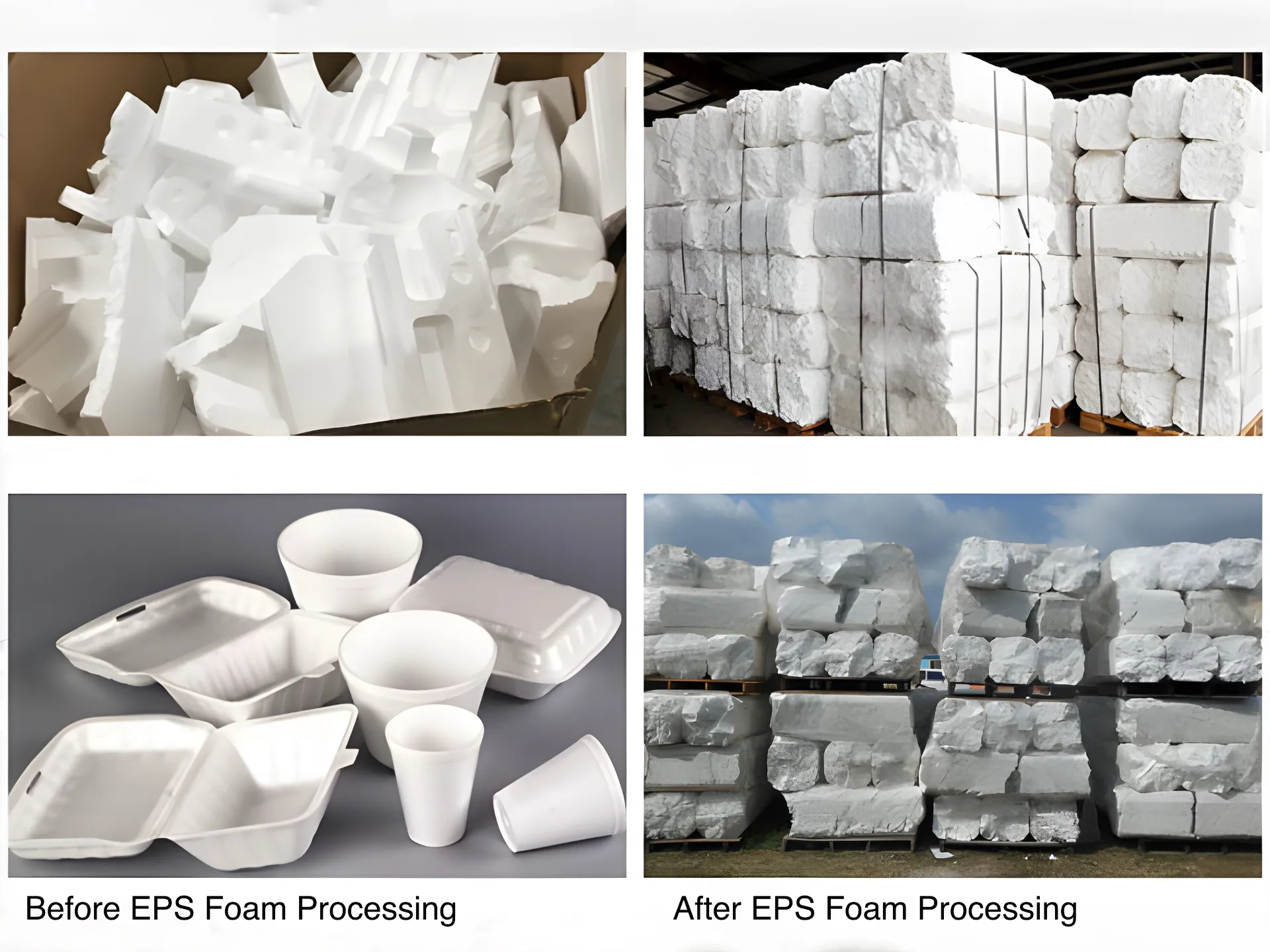

3. Dannelse af tætte blokke

- Det komprimerede skum ekstruderes til tætte, ensartede blokke eller træstammer.

- Disse blokke er nemmere at håndtere, opbevare og transportere, hvilket gør dem velegnede til genbrug eller bortskaffelse.

4. Udskrivning og opsamling

5. Fordele

Specifikation

| Model | GL-HM100 | GL-HM200 | GL-HM400 |

|---|---|---|---|

| Skrue diameter | Φ100 mm | Φ180–120 mm | Φ180–120 mm |

| Skruelængde | 1050 mm | 2500 mm | 2500 mm |

| Skruehastighed | 150 r/min | 110 r/min | 110 r/min |

| Produktion | 40-50 kg/t | 80–120 kg/t | 180–200 kg/t |

| Skærmmaskestørrelse | 40 mm | 50 mm | 50 mm |

| Ekstruderingstrykinterval | 300 min | 386 min | 366 min |

| Motorkraft | 5,5 KW | 15 KW | 22 KW |

| Varmekraft | 4 KW | 10 KW | 14 KW |

| Kraft til knusemaskine | 1,5 KW | 2,2 + 2,2 KW | 2,2 + 2,2 + 2,2 + 2,2 KW |

| Antal knusere | 9 sæt | 9 + 10 sæt | 9 + 10 + 9 + 10 sæt |

| Knuserhastighed | 110 r/m | 110 mm | 110 mm |

| Dimensioner | 1410×1085×1600 mm | 2030×1400×2050 mm | 3400×1880×2550 mm |

| Vægt | 1000 kg | 1800 kg | 2500 kg |

Garanti og installation

Hver genbrugsmaskine inkluderer en 1-års begrænset garanti. Vi leverer installationstjenester, hvor vores ingeniører besøger dit websted for at hjælpe med opsætningsprocessen. Der kan også aftales med regelmæssige vedligeholdelsesmandskaber og driftskonsulenter.

Spørg nu

For at få de seneste priser og leveringstider, send os en besked ved at bruge formularen nedenfor.