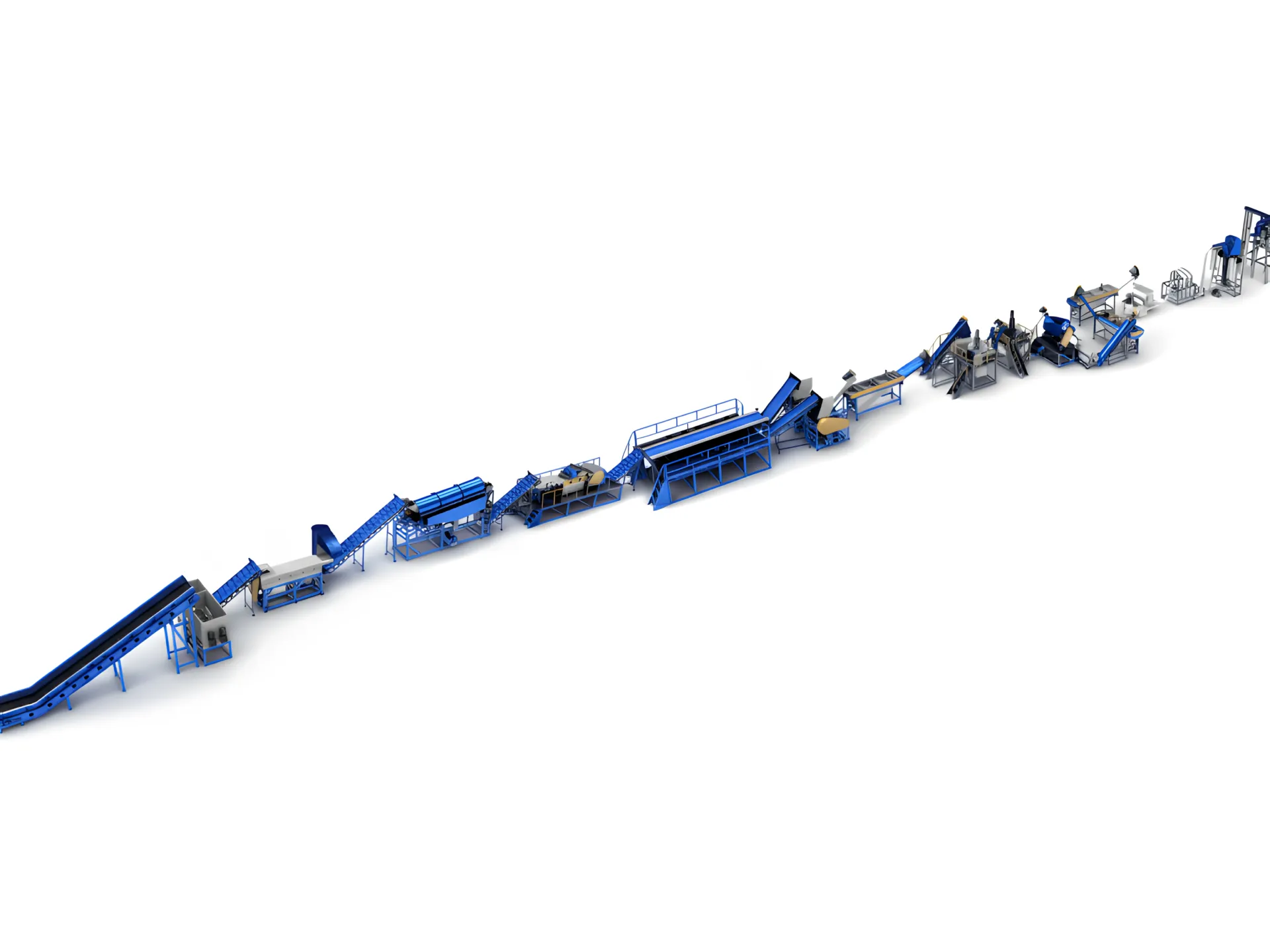

HDPE & PP Rigid Plastic Washing & Recycling Line

Turn bulky HDPE/PP waste—such as bottles, crates, drums, and pipes—into clean, high-value recycled flakes. Our fully automated line is engineered for high throughput, superior cleaning, and maximum efficiency.

Transform Waste into a Valuable Commodity

Investing in our recycling line is a smart choice for your business and the planet. Create a new revenue stream from plastic waste while meeting your sustainability goals.

High-Quality Output

Our multi-stage washing and purification process meticulously removes contaminants like dirt, labels, and adhesives, producing clean, consistent flakes suitable for a wide range of manufacturing applications.

Automated Efficiency

Designed for high throughput and reliability, our streamlined process from shredding to drying is fully automated to minimize downtime, reduce labor costs, and maximize your operational output.

Economic & Environmental Advantage

Turn a waste liability into a valuable asset. Produce cost-effective recycled flakes that reduce the demand for virgin plastic, conserve natural resources, and significantly lower your carbon footprint.

From Bulky Waste to Clean Flakes: The Process

Size Reduction

Bulky rigid plastics are fed into a powerful shredder and granulator, reducing them to small, uniform flakes.

Washing & Separation

Flakes undergo intensive cleaning in friction washers and are purified in float-sink tanks to remove contaminants.

Drying

A dewatering machine and thermal dryer work in tandem to remove moisture, achieving a final humidity level ideal for storage or sale.

Collection

Clean, dry flakes are collected in a storage silo, often with a dust-removal system, ready for packaging and reuse.

Key Modules of the Recycling Line

Our recycling lines are modular and can be customized to your specific input materials and output requirements. A typical high-performance line includes:

Primary Size Reduction

A robust single-shaft shredder followed by a crusher (granulator) efficiently reduces bulky items into uniform flakes, preparing them for the washing process. Our shredders feature large chambers and fast hydraulic rams for maximum throughput.

Intensive Washing System

A high-speed friction washer scrubs flakes to remove dirt and surface residues. For heavily soiled materials, an optional hot wash system can be integrated to break down stubborn contaminants like oil and glue.

Purification System

A float-sink tank uses water density to perform a critical separation step. It allows valuable HDPE/PP flakes to float while heavier contaminants (PET, PVC, metal, glass) sink and are removed from the system.

High-Efficiency Drying System

A centrifugal dewatering machine first mechanically removes the majority of surface water. A subsequent thermal pipe drying system uses hot air to reduce the final moisture content to less than 1%, ensuring the flakes are ready for high-quality pelletizing or manufacturing.

Technical Specifications & Consumption

| Capacity Options | 500 kg/hr to 2000 kg/hr |

|---|---|

| Applicable Materials | HDPE, PP (Bottles, Crates, Pipes, Drums, etc.) |

| Final Product | Clean, high-purity plastic flakes |

| Final Moisture Content | < 1% |

| Control System | Automated PLC with HMI |

| Electricity | ~ 50 - 80 kWh / Ton |

|---|---|

| Water | ~ 0.8 - 1.5 Tons / Ton (Recirculation standard) |

| Compressed Air | ~ 0.5 - 1 m³ / Ton |

| Detergent (Optional) | ~ 2 - 4 kg / Ton |

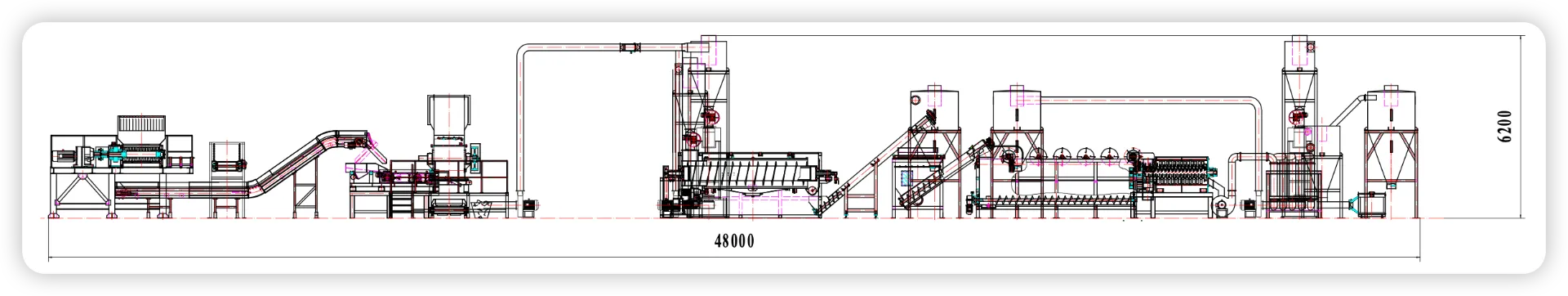

System Layout Diagram

Frequently Asked Questions

What is the quality of the final recycled plastic flakes?

Our system is designed to produce high-purity flakes. With proper sorting and the optional hot wash system, the final product can achieve a quality level suitable for producing new pipes, containers, automotive parts, and more, often rivaling virgin materials in certain applications.

How much water does the recycling line consume?

While washing requires water, our lines are designed with efficiency in mind. All our systems incorporate water recirculation and filtration, which significantly minimizes fresh water consumption to approximately 0.8-1.5 tons per ton of plastic processed.

Can this line be customized for my specific needs?

Absolutely. Our lines are fully modular. We can adjust the capacity (from 500 to 2000 kg/hr), add or remove specific modules (like hot washing or a second float-sink tank), and configure the layout to fit your facility's space and your material's contamination level.

Partner with Us for Your Recycling Needs

All our recycling machines come with a comprehensive 1-year limited warranty. Contact us today to discuss your project, get current pricing, and receive a customized layout for your operation.