Optimer din genbrugsproces med en avanceret makuleringsmaskine til affaldsplastfilm

I nutidens miljøbevidste verden er det altafgørende at håndtere plastikaffald effektivt. For virksomheder, der ønsker at forbedre deres genbrugsprocesser, kan investering i en state-of-the-art makuleringsmaskine til affaldsplastik være en game-changer. Denne artikel udforsker de vigtigste funktioner og ydeevnefordele ved en avanceret makuleringsmaskine designet til at opfylde kravene til moderne genbrugsoperationer.

Højeffektiv makulering med kontinuerlig fremføring

En af de iøjnefaldende egenskaber ved denne makuleringsmaskine til affaldsplastfilm er dens innovative materialesilodesign, som muliggør en komplet bevægelsescyklus. Dette giver mulighed for ubegrænset fodring, hvilket sikrer, at materialer makuleres uden fastklemning, og dermed opnås høj makuleringseffektivitet. Dette kontinuerlige tilførselssystem optimerer ikke kun driften, men øger også gennemløbet, hvilket gør det til en ideel løsning til faciliteter, der håndterer store mængder plastfilmaffald.

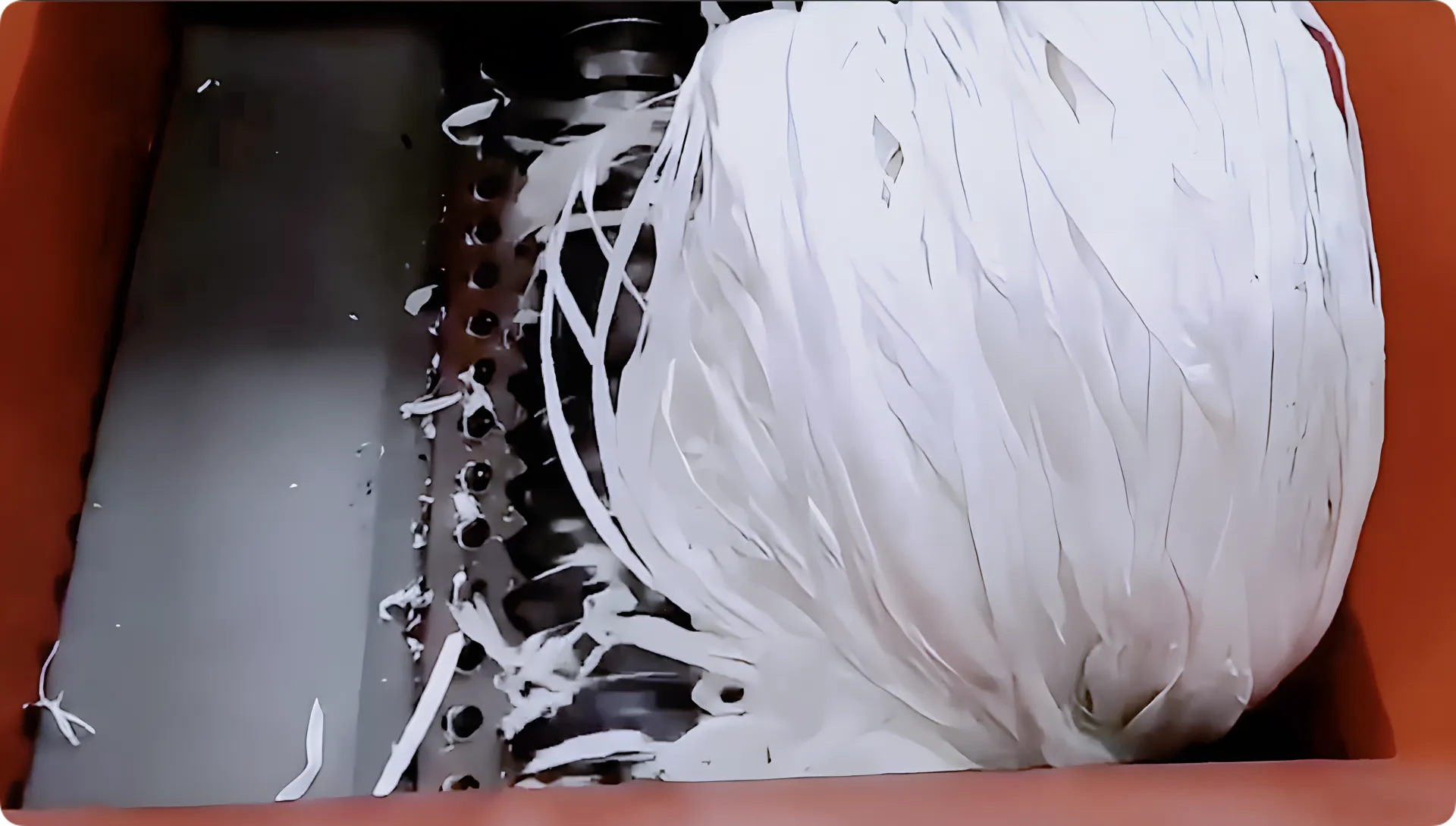

Forbedret produktivitet med specialfremstillet hovedaksel

Makuleringsmaskinens hovedaksel er specialfremstillet med en stor rotationsdiameter, hvilket giver en betydelig makuleringskontaktflade. Dette unikke design øger interaktionen mellem materialet og makuleringsmekanismerne og øger derved produktiviteten. Uanset om du behandler industrielle mængder affald eller håndterer forskellige materialer, sikrer skaftet med stor diameter ensartet, effektiv makulering.

Vibrationsreduktion og komponentbeskyttelse

For at forbedre ydeevnen yderligere har makuleringsmaskinen koblinger i dens transmissionsdele. Dette strategiske designvalg hjælper med at reducere vibrationer, hvilket ikke kun beskytter hovedakslen og reduktionen, men også sikrer, at der ikke er noget tab af kraft under drift. Ved at minimere vibrationer forlænger maskinen levetiden for kritiske komponenter og bevarer ensartet ydeevne over tid.

Effektiv materialeskæring og reduceret vedligeholdelse

Udstyret med en fast kniv i både toppen og bunden af hovedakslen skærer makulatoren effektivt materialer uden at forårsage sammenfiltring omkring skaftet. Dette design sikrer, at de makulerede stykker er små og håndterbare, hvilket letter håndtering og forarbejdning nedstrøms. Desuden reducerer reduktionen af materiale, der omslutter akslen, den nødvendige vedligeholdelse betydeligt, hvilket holder maskinen kørende problemfrit med mindre nedetid.

Automatiseret og sikker drift med PLC kontrolsystem

Automatisering er kernen i denne makuleringsmaskine. Den har et avanceret elektronisk styresystem med PLC-programmering og inkluderer funktioner som start, stop, fremad, baklæns og automatisk overbelastningsbeskyttelse. Denne automatisering sikrer ikke kun stabil og sikker drift, men reducerer også behovet for manuel indgriben og sparer derved arbejdsomkostninger. Den brugervenlige grænseflade og de programmerbare kontroller gør det nemt for operatører at styre makuleringsprocessen effektivt og sikkert.

Specifikation

| Shredder model | Skaftdiameter (mm) | Flyttekniv Antal. (stk) | Fast kniv Antal. (stk) | Maksimal kapacitet (kg/t) | Motoreffekt (KW) | Sukkermundens størrelse (L x B) (mm) | Værtsvægt (kg) | Dimensioner (L x B x H) (mm) |

|---|---|---|---|---|---|---|---|---|

| RTM-L2455 | 300 | 24 | 2 | 400 | 22 | 800 x 1300 | 3600 | 3250 x 1500 x 2350 |

| RTM-L3063 | 300 | 30 | 2 | 550 | 30 | 900 x 1300 | 4000 | 3250 x 1750 x 2350 |

| RTM-L3980 | 350 | 39 | 2 | 750 | 45 | 1100 x 1500 | 6000 | 4150 x 1900 x 2450 |

| RTM-L36100 | 400 | 36 | 2 | 1200 | 55 | 1300 x 1800 | 8000 | 4700 x 2550 x 2650 |

| RTM-L42120 | 400 | 42 | 2 | 1500 | 75 | 1500 x 1900 | 9500 | 5350 x 2850 x 2760 |

| RTM-L64160 | 500 | 64 | 4 | 5000 | 132 | 2200 x 2200 | 18000 | 5900 x 3050 x 2960 |

Konklusion

At investere i en makuleringsmaskine til affaldsplastfilm med disse avancerede funktioner repræsenterer en strategisk beslutning for virksomheder, der sigter mod at forbedre deres genbrugseffektivitet og operationelle produktivitet. Med sin kombination af kontinuerlig fodring, specialfremstillede komponenter, vibrationsreduktion, effektiv materialeskæring og automatisering er denne makuleringsmaskine designet til at imødekomme udfordringerne ved moderne affaldshåndtering og genbrugsfaciliteter. Omfavn teknologi for at gøre din genbrugsproces mere effektiv, sikker og omkostningseffektiv.