Key Features of Our Industrial Shredders

Our shredder can grind various types of plastics including ABS, Acetal, Acrylic, HDPE, HMWHDPE, LDPE, LLDPE, Nylon 6 and 66, PC PET Polyamide Polyester PP PS PU PUR PVC TPE TPO UHW-PE and composites to the required size.

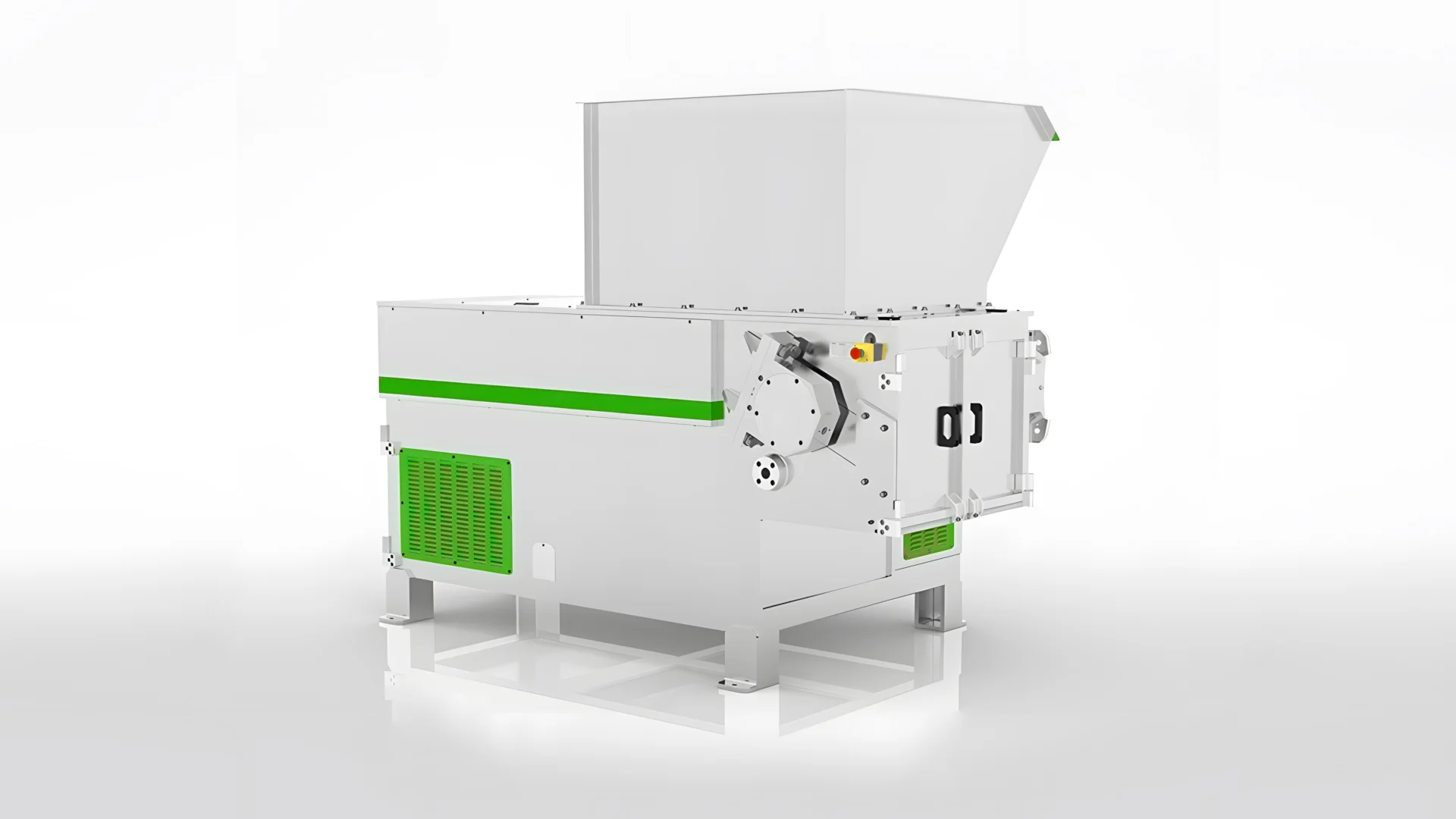

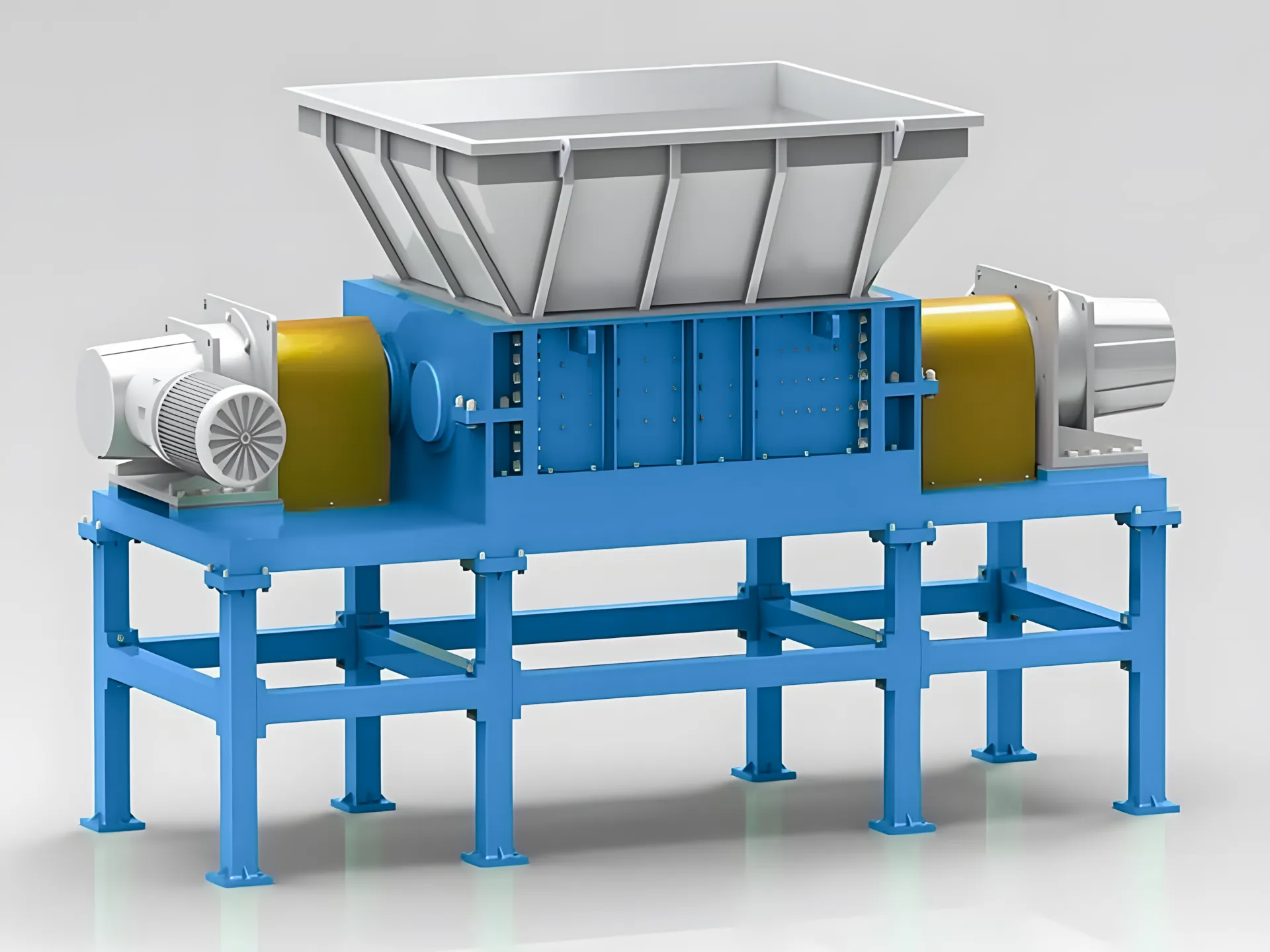

Our industrial shredders are engineered for durability and high-performance waste processing. With a variety of models, we cater to diverse shredding needs, ensuring efficient and secure waste disposal. Explore the standout features that make our shredders the preferred choice in the industry.

Heavy-Duty Construction

Built to last, our industrial shredders feature heavy-duty construction that withstands demanding operational environments.

- Durable materials

- Robust design

- High operational efficiency

Versatile Shredding Options

Our shredders offer multiple shredding options, making them suitable for various materials including plastics, metals, and paper.

- Multiple blade configurations

- Convenient size options

- Customizable settings

Energieffektivitet

Designed with energy efficiency in mind, our industrial shredders help reduce operational costs while maximizing output.

- Low power consumption

- High throughput

- Eco-friendly design

Safety Features

Safety is our priority; our shredders come equipped with advanced safety features to protect operators.

- Automated shut-off

- Emergency stop button

- Protective covers

Brugervenlig grænseflade

Our shredders are designed with user-friendly controls ensuring ease of operation for all users.

- Intuitive controls

- Clear display

- Simple setup

Comprehensive Support

We provide extensive customer support, offering guidance from purchasing to maintenance, ensuring your shredder operates optimally.

- 24/7 support

- Maintenance services

- Parts availability