Inden for plastgenbrug, Premium Standard Plastgranulatormaskiner eksemplificere effektivitet og overlegen ydeevne. Disse robuste maskiner er omhyggeligt konstrueret til at omdanne forskellige plastmaterialer til ensartede flager eller genslibninger, der tjener som en kritisk komponent i omfattende genbrugssystemer, herunder PET-flaskevask og plastfilmgenbrugslinjer.

Arbejdsprincip

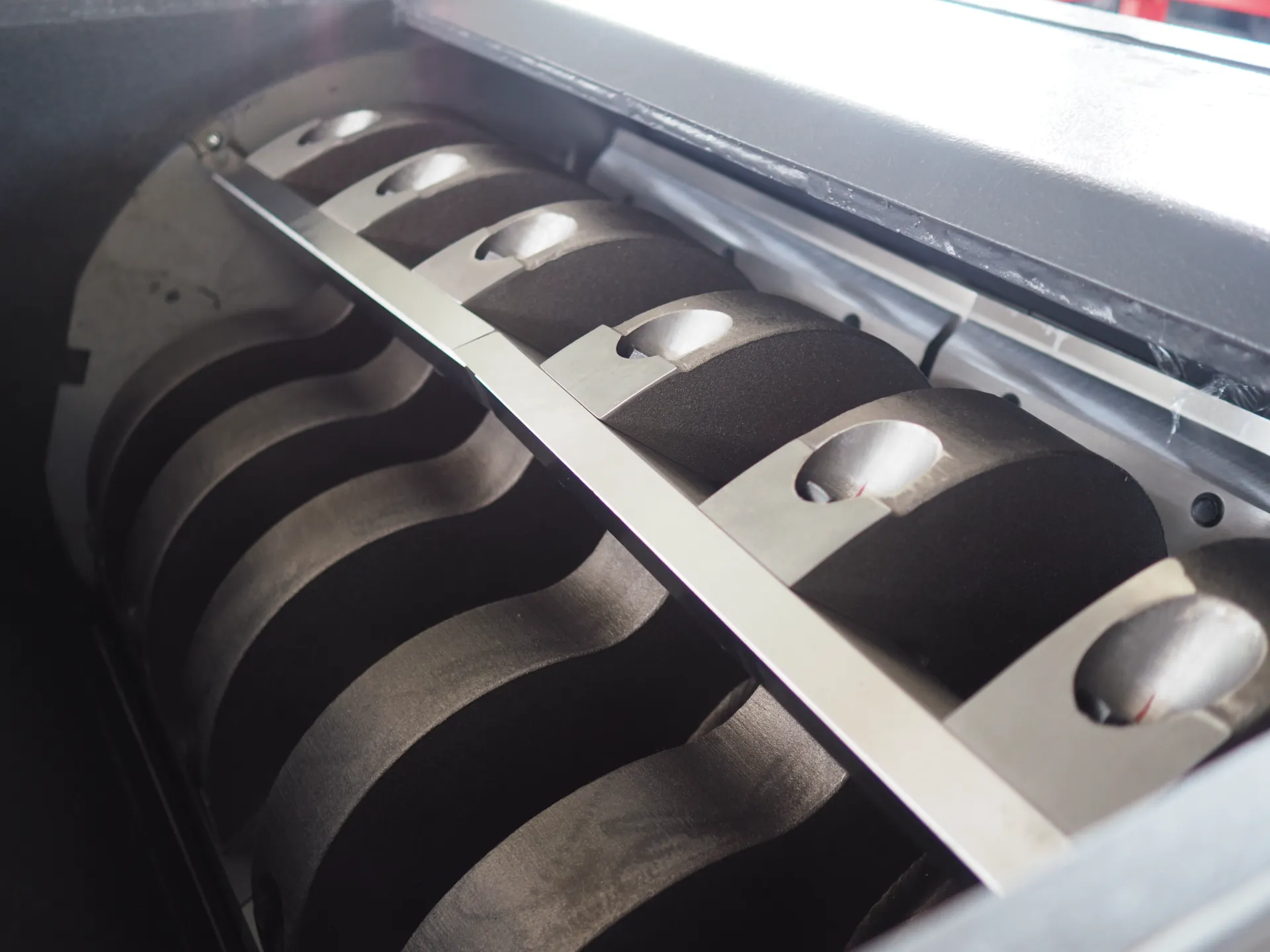

I hjertet af disse premium granulatorer ligger en åben rotor udstyret med kraftige knive. Disse knive, der er konfigureret i et dobbelt-saks-skåret eller V-formet arrangement, samarbejder med stationære knive i skærekammeret. Da rotoren arbejder ved høje hastigheder, gennemgår plastmaterialet kontinuerlig skæring, indtil det opnår den ønskede størrelse til at passere gennem et sigtefilter, hvilket sikrer ensartet granulatkvalitet.

Tekniske specifikationer

- Knive: Rotoren og de stationære knive er fremstillet af D2-stål med høj kulstof, højkrom, kendt for sin enestående holdbarhed.

- Skærmfilter: Skærmefiltre, der kan tilpasses, er tilgængelige med størrelser fra 10 mm til 100 mm, hvilket giver mulighed for præcis kontrol over outputgranulatstørrelsen.

- Hydraulisk adgang: Skærekammeret har hydraulisk assisteret adgang, hvilket letter ligetil knivjusteringer og vedligeholdelse.

- Materiale kompatibilitet: Disse granulatorer er dygtige til at behandle forskellige plastmaterialer, herunder flasker, film og små stive plastik.

Model specifikationer

| Model | Rotor diameter | Rotorbredde | Roterende hastighed | Ca. Produktion | Motorkraft |

|---|---|---|---|---|---|

| RTM600 | ⌀450 mm | 600 mm | 400-600 rpm | 300 kg/t | 37KW |

| RTM800 | ⌀500 mm | 800 mm | 400-600 rpm | 600 kg/t | 45KW |

| RTM1000 | ⌀600 mm | 1000 mm | 400-600 rpm | 900 kg/t | 75KW |

| RTM1200 | ⌀700 mm | 1200 mm | 400-600 rpm | 1200 kg/t | 90KW |

Ansøgninger

Disse alsidige granulatorer er ideelle til forarbejdning:

- Plastflasker: Reducerer effektivt PET-flasker til granulat til genbrug.

- Plastfilm: Håndtering af film af varierende tykkelse med præcision.

- Stiv plast: Behandling af små stive plastikkomponenter med lethed.

For øget driftsfleksibilitet er våd plastgranulatormodeller tilgængelige. Disse har gummitætning og en vandtilførselsslange til knivafkøling under drift, hvilket effektivt styrer varmeudviklingen og opretholder skæreeffektiviteten.

Konklusion

Investering i Premium standard plastgranulatormaskiner betyder at forpligte sig til øget effektivitet og overlegen kvalitet i plastgenbrugsoperationer. Deres robuste konstruktion, avancerede funktioner og tilpasningsevne sikrer langsigtede besparelser og øget produktivitet.

Garanti & Support

Hver maskine leveres med 1 års begrænset garanti. Vores dedikerede supportteam står til rådighed for at løse eventuelle spørgsmål eller bekymringer, hvilket sikrer uafbrudt drift.

Bemærk: Tilpasningsmuligheder er tilgængelige for at opfylde specifikke driftskrav. For detaljeret information og forespørgsler, kontakt os venligst direkte.