Nyheder om genbrug

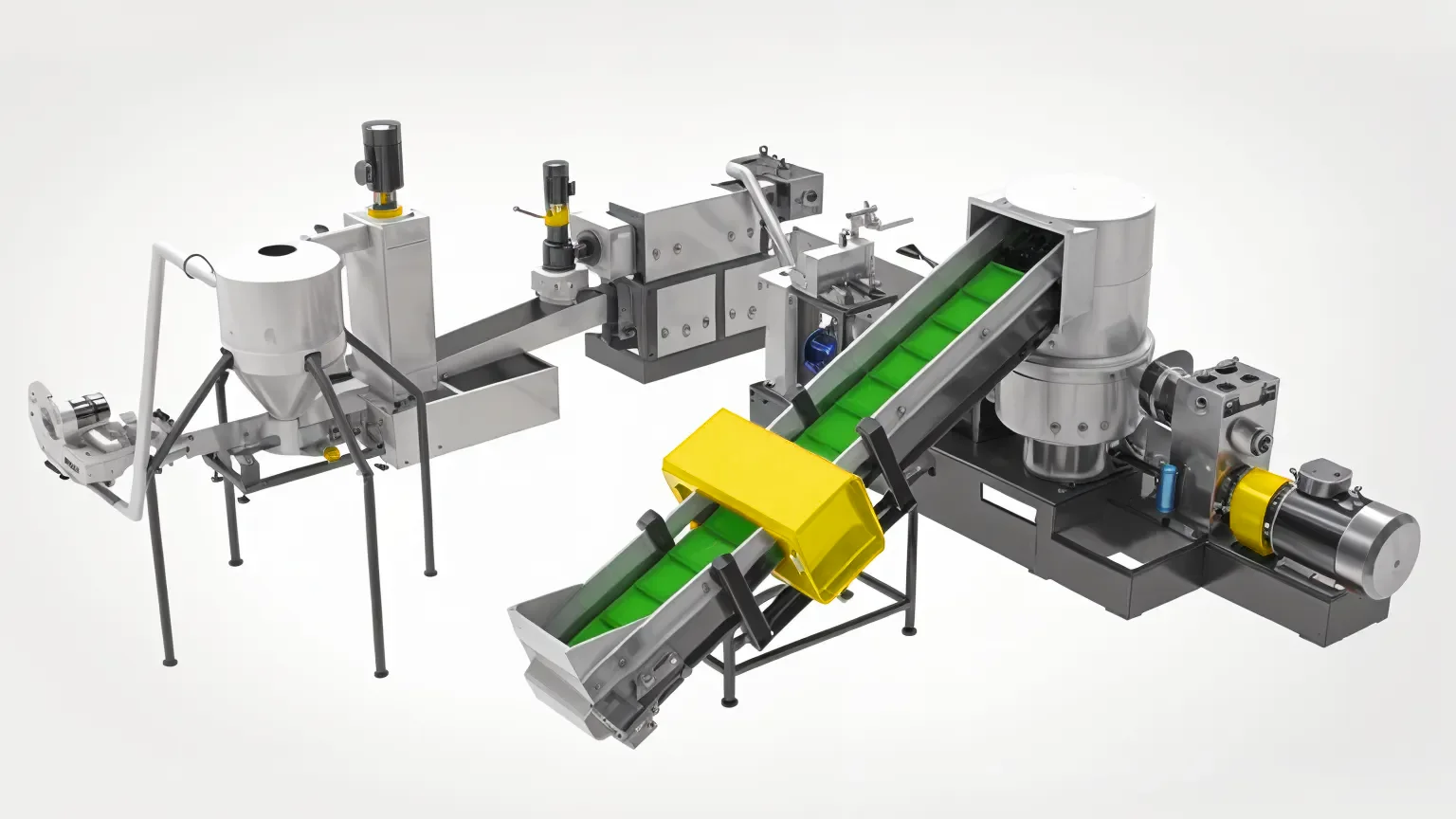

Selecting the right plastic pelletizer is crucial for manufacturers aiming to enhance their production efficiency and product quality. This guide explores key factors to consider when choosing a plastic pelletizer, including the type of materials processed, production capacity, and energy efficiency.

Reliable Equipment for Secondary Wood Processing Industries

Industries involved in secondary wood processing, such as pallet, crate, and container manufacturing, as well as truss and structural building component production, and particleboard, chipboard, and MDF manufacturing, all benefit significantly from using Rumtoo wood grinders for pallet recycling. Whether the goal is to reduce pallet scrap volume to cut down on dumpster tipping fees or to transform pallet scrap into valuable products like animal bedding, boiler fuel, or pellets, Rumtoo wood grinders are an excellent choice for any business.

Advanced Solutions for Plastic Pipe Processing

Rumtoo offers a range of solutions for processing plastic pipes, including vertical feed single-shaft shredders and horizontal shredders for long pipe sections. Over half of the top 50 pipe, profile, and tubing extruders rely on Rumtoo recycling equipment.

Plastic pelletizer machines are crucial in the plastics industry, turning raw plastic materials into pellets that can be used for manufacturing various products. If you're considering investing in one, it's important to understand the factors that influence their cost. This article delves into the key elements affecting the pricing of plastic pelletizer machines, including machine specifications, production capacity, and brand reputation.

When it comes to purchasing a plastic pelletizer machine, potential buyers are often faced with a variety of choices, ranging from budget-friendly models to high-end options. This guide provides an in-depth review of different models available in the market, highlighting their features, advantages, and price points to help you make an informed decision.

Unmatched Technology in Film and Fiber Shredding

Rumtoo, the world leader in film shredding equipment, offers the RTM Series shredders, the only machines equipped with the patented Cutting System. This groundbreaking design overcomes the common issues faced with traditional film and fiber grinders, such as self-feeding and rotor wrapping. The system ensures precise cuts and high bulk densities, making it an essential component of effective film resin reclaim systems in use today.

The Only Choice for Film and Fiber Recycling

Når det kommer til film shredding machines, Rumtoo's RTM Series stands out. With the unique technology, these shredders deliver unparalleled performance in film and fiber recycling. Rumtoo's expertise in size reduction is evident in the quality and reliability of their equipment.

Versatile Solutions for Expanding Recycling Needs

As the recycling industry evolves, Rumtoo's film and fiber shredders are designed to handle an increasing variety of plastic and fiber scrap materials. From highly tear-resistant synthetic fibers to textiles and ropes, Rumtoo grinders efficiently process even the toughest materials. The latest advancements, including the film and fiber rotor, ensure these machines meet the highest standards in plastic grinding technology.

Find Your Perfect Film and Fiber Recovery System

Explore Rumtoo's innovative solutions and find the film and fiber recovery system that fits your needs. Contact Rumtoo today to discover how their cutting-edge shredders can enhance your recycling operations.

Introduction to Plastic Container Recycling

Plastic bottles, buckets, barrels, drums, IBCs (intermediate bulk containers), totes, and tanks are ubiquitous in various industries due to their durability and reusability. However, these containers eventually become damaged, contaminated, or simply wear out. When they reach the end of their lifecycle, recycling becomes essential. The first crucial step in the recycling process is size reduction, a field where Rumtoo excels.

When it comes to PET bottle recycling, Rumtoo's industrial shredders are leading the way. These machines are specifically designed to handle the complexities of recycling plastic bottles, providing an efficient and reliable solution for plastic container recycling. Often referred to as PET bottle shredders or PET bottle grinders, Rumtoo's shredding technology is at the forefront of plastic waste management.

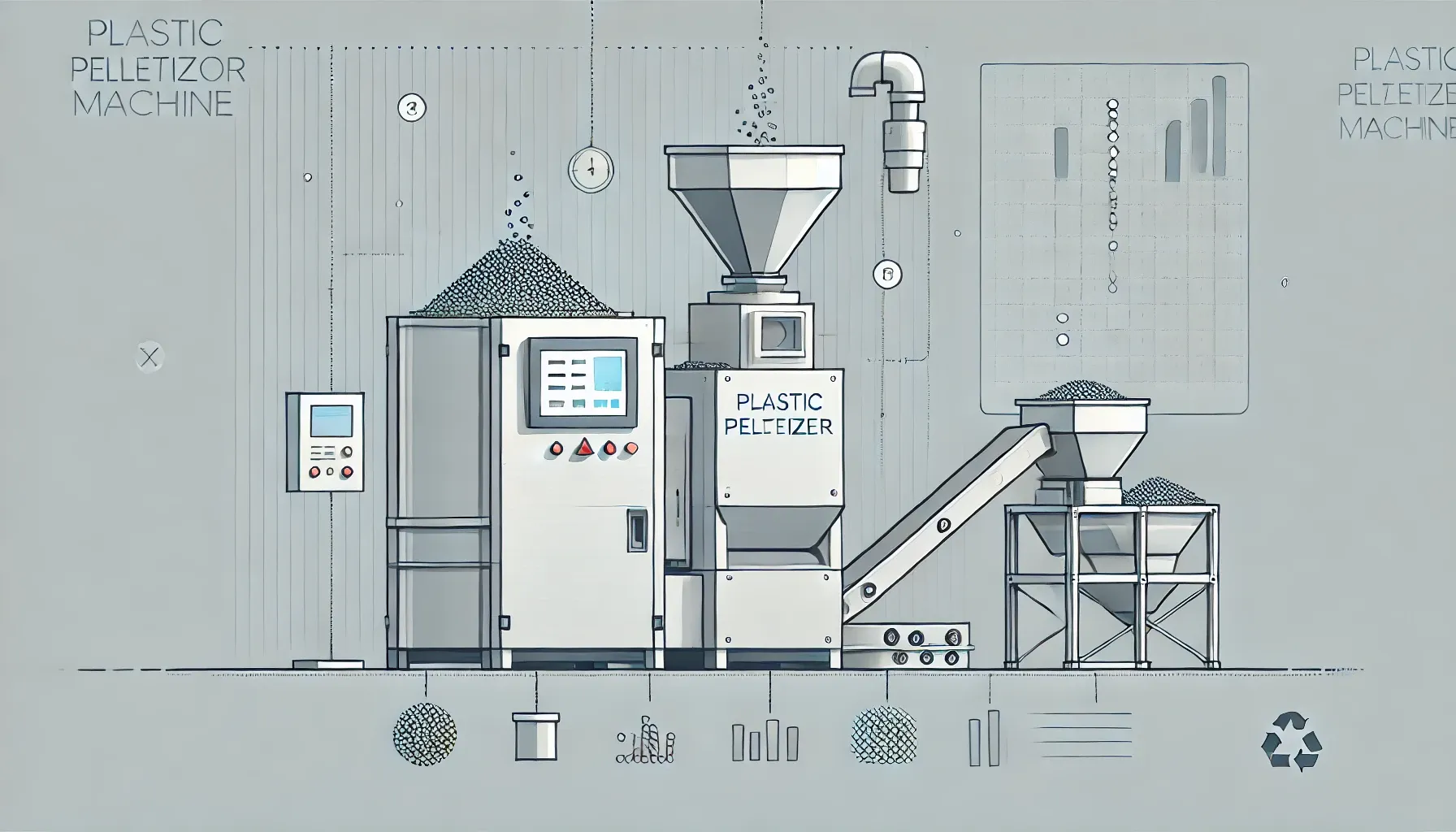

Introduktion til plastpelleteringsmaskiner

En plastpelletizer er en afgørende maskine i genbrugs- og fremstillingsindustrien, designet til at omdanne plastikaffald til brugbare plastpiller. Disse pellets tjener som råmateriale til fremstilling af nye plastprodukter, hvilket gør pelletizeren til en nøglespiller i at fremme bæredygtig praksis.

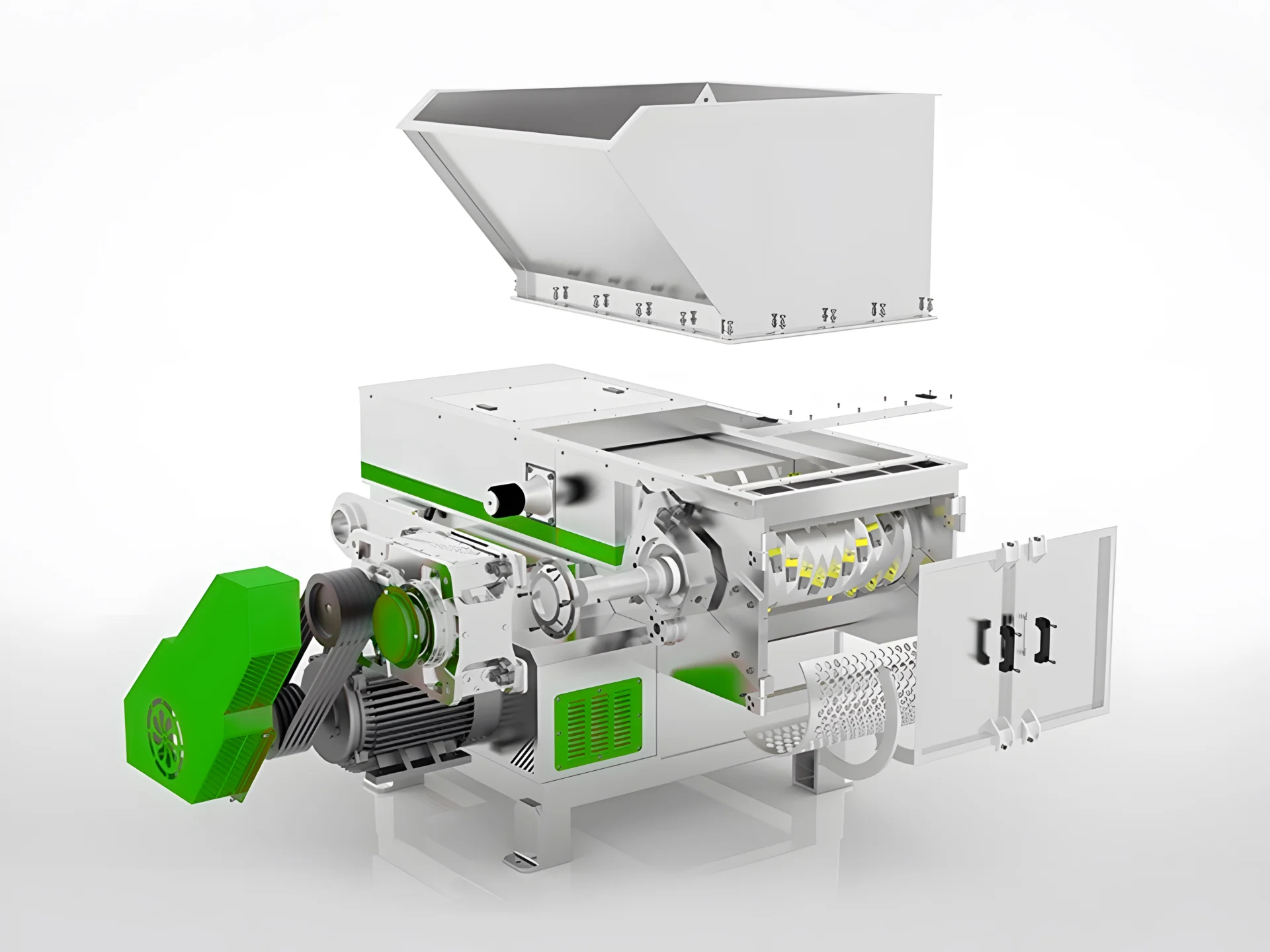

In today's world, where plastic waste is a growing concern, recycling has become more crucial than ever. One of the key components in the plastic recycling process is the granulator, a machine that breaks down plastic waste into smaller, more manageable pieces called granules. These granules can then be reused to create new plastic products, reducing the need for virgin plastic and minimizing the environmental impact of plastic waste.

However, not all plastic granulators are created equal. There are various types of granulators designed to handle different kinds of plastic waste and cater to specific recycling needs. In this article, we'll explore the different types of plastic granulators and help you determine which one suits your recycling needs best.