Nyheder om genbrug

Kategorier Nyheder om genbrug

Udgivet den

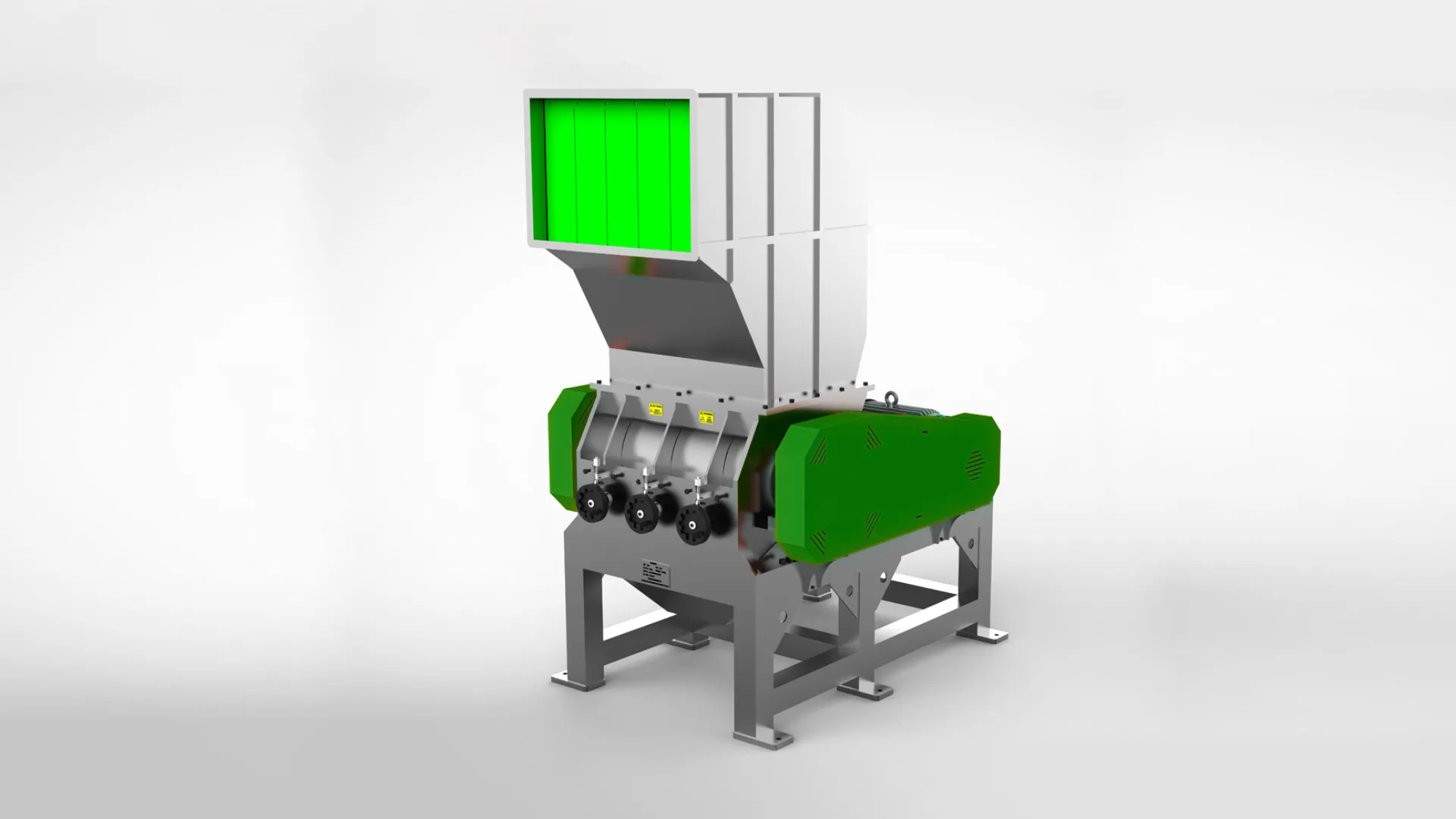

Det er afgørende at vælge den ideelle PVC-rørkværn for effektiv håndtering og genbrug af plastaffald. Denne guide gennemgår de vigtigste faktorer, der skal overvejes, lige fra motorkraft og knivkvalitet til kapacitet, holdbarhed, sikkerhedsfunktioner og omkostningseffektivitet, så du kan vælge en maskine, der opfylder dine specifikke driftsbehov og leverer et stærkt investeringsafkast.

Kategorier Nyheder om genbrug

Udgivet den

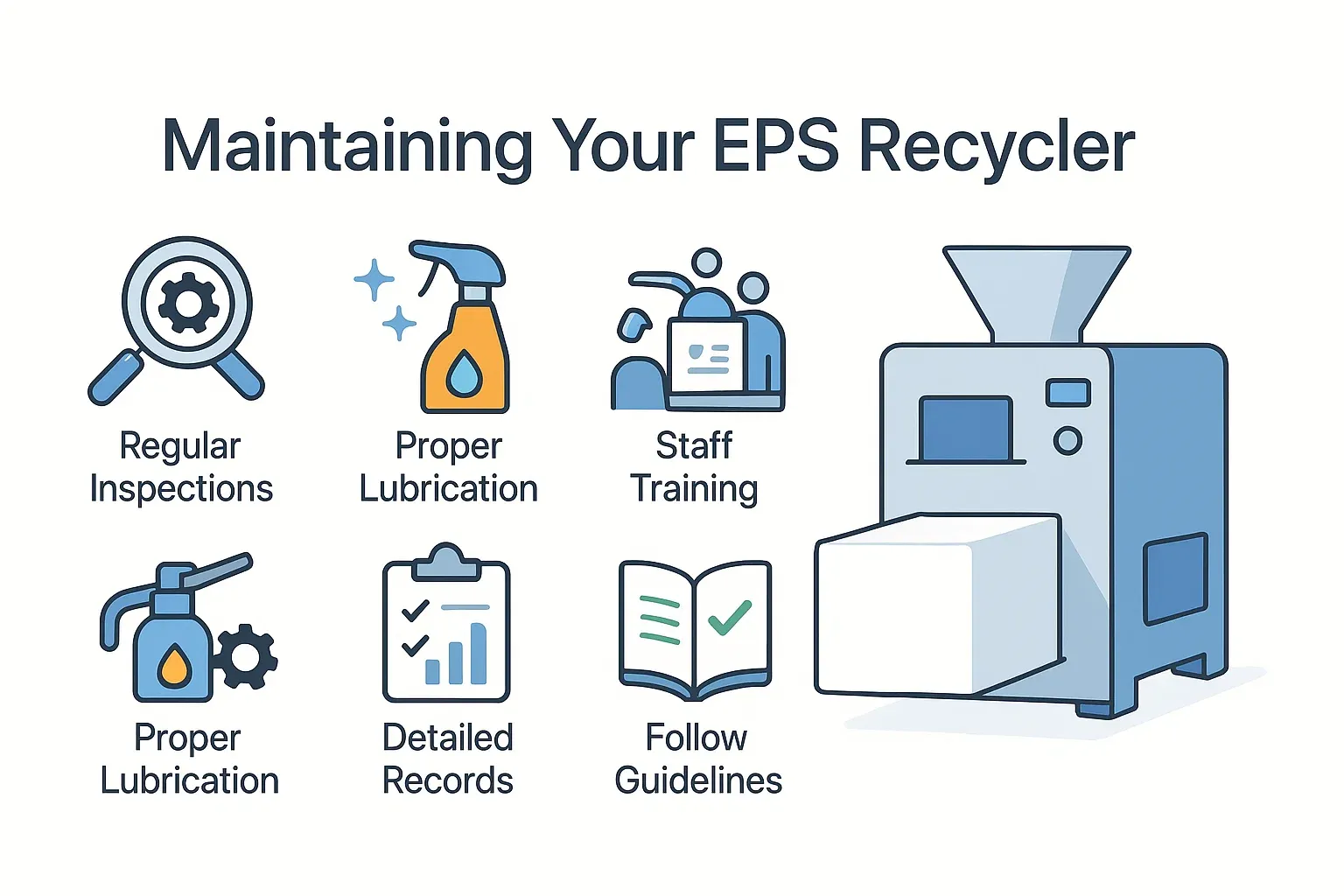

Lås op for hemmelighederne bag at forlænge levetiden og optimere ydeevnen af dit vigtige EPS-genbrugsudstyr. Denne guide tilbyder brugbare vedligeholdelsestips til maskiner som EPS-skumkomprimatorer – fra regelmæssige inspektioner og daglig rengøring til korrekt smøring og personaleuddannelse – alt sammen designet til at minimere nedetid, spare omkostninger og sikre, at dine operationer kører effektivt og sikkert. Investering i proaktiv pleje er nøglen til bæredygtig EPS-genbrug.

Kategorier Nyheder om genbrug

Udgivet den

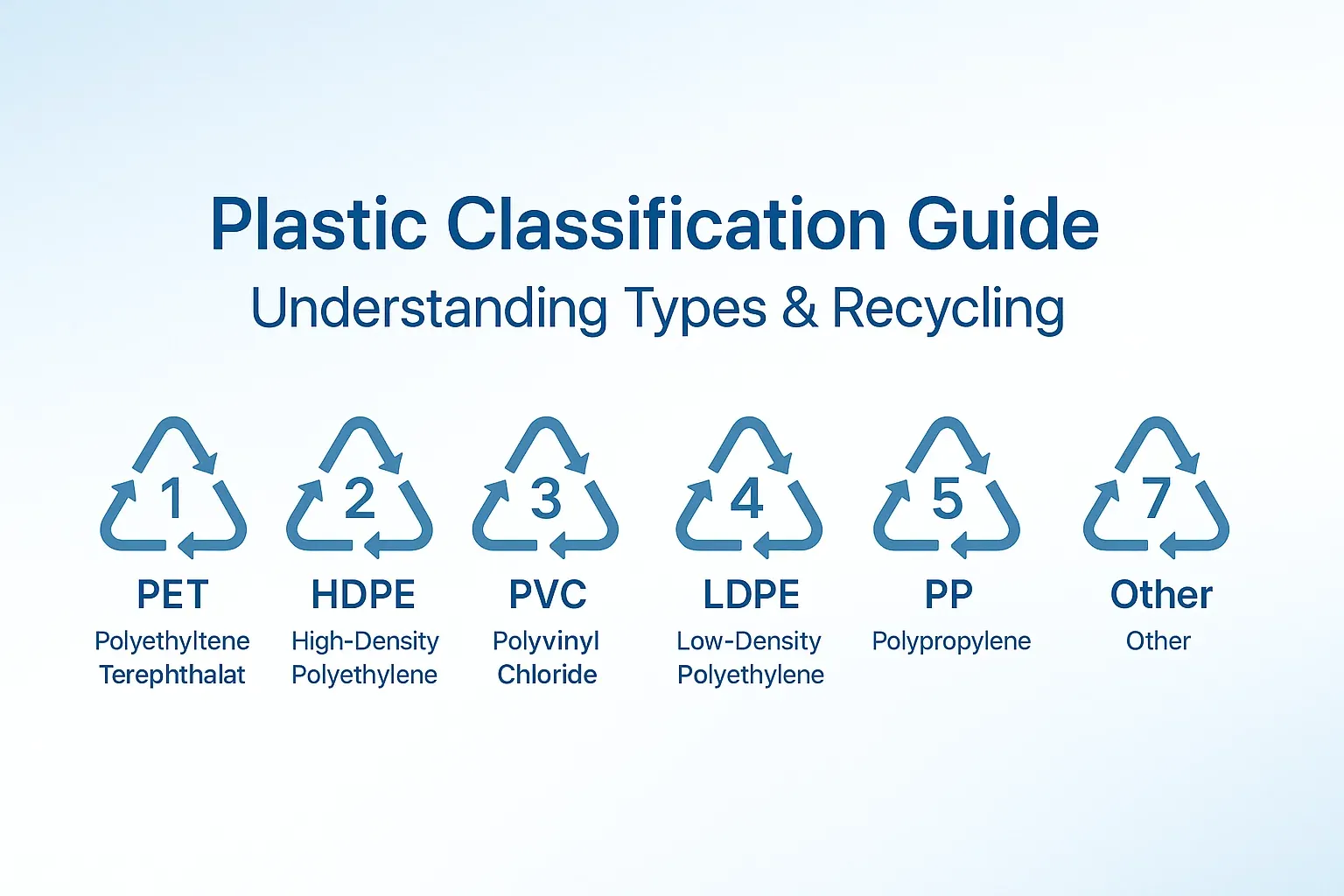

Forstå polyvinylchlorid (PVC), identificeret ved genbrugskode 3. Denne vejledning udforsker PVC's egenskaber, kompleksiteten af dets genbrug på grund af klorindhold og tilsætningsstoffer, miljøhensyn og giver klare råd om korrekte bortskaffelsesmetoder og hvordan man finder lokale genbrugsmuligheder.

Kategorier Nyheder om genbrug

Udgivet den

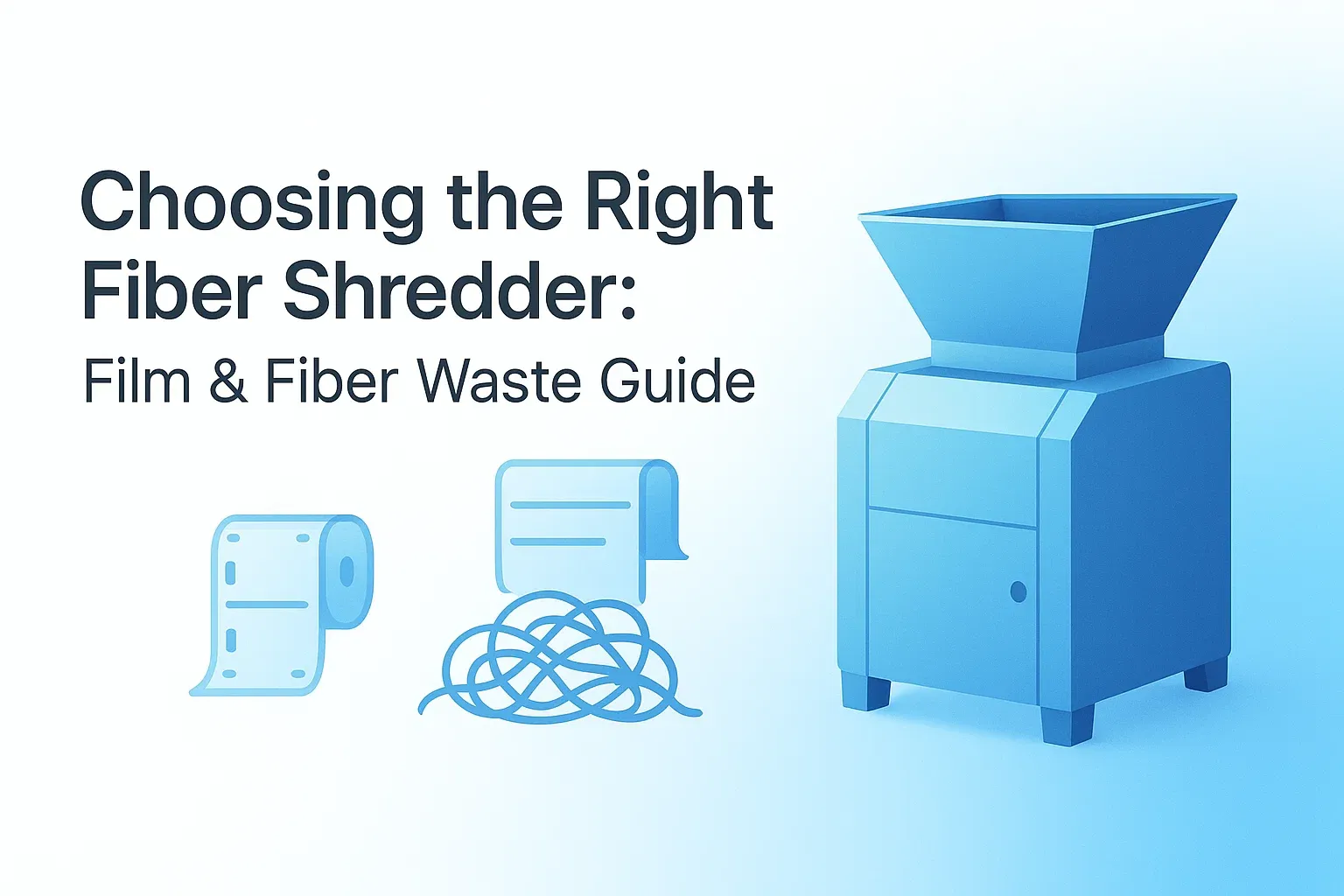

Det kan være komplekst at vælge den ideelle fiberkværn til dine specifikke film- og fiberaffaldsmaterialer. Denne omfattende guide forenkler processen og tilbyder praktiske tips til at forstå dine behov – fra materialetype (film, tekstiler, industrielle fibre) og forarbejdningsvolumen til den ønskede partikelstørrelse. Opdag nøglefaktorer som kværntyper (enkeltaksel, dobbeltaksel), effekt, vedligeholdelse og hvad du skal kigge efter hos topmærker for at træffe en informeret beslutning om effektiv affaldshåndtering.

Kategorier Nyheder om genbrug

Udgivet den

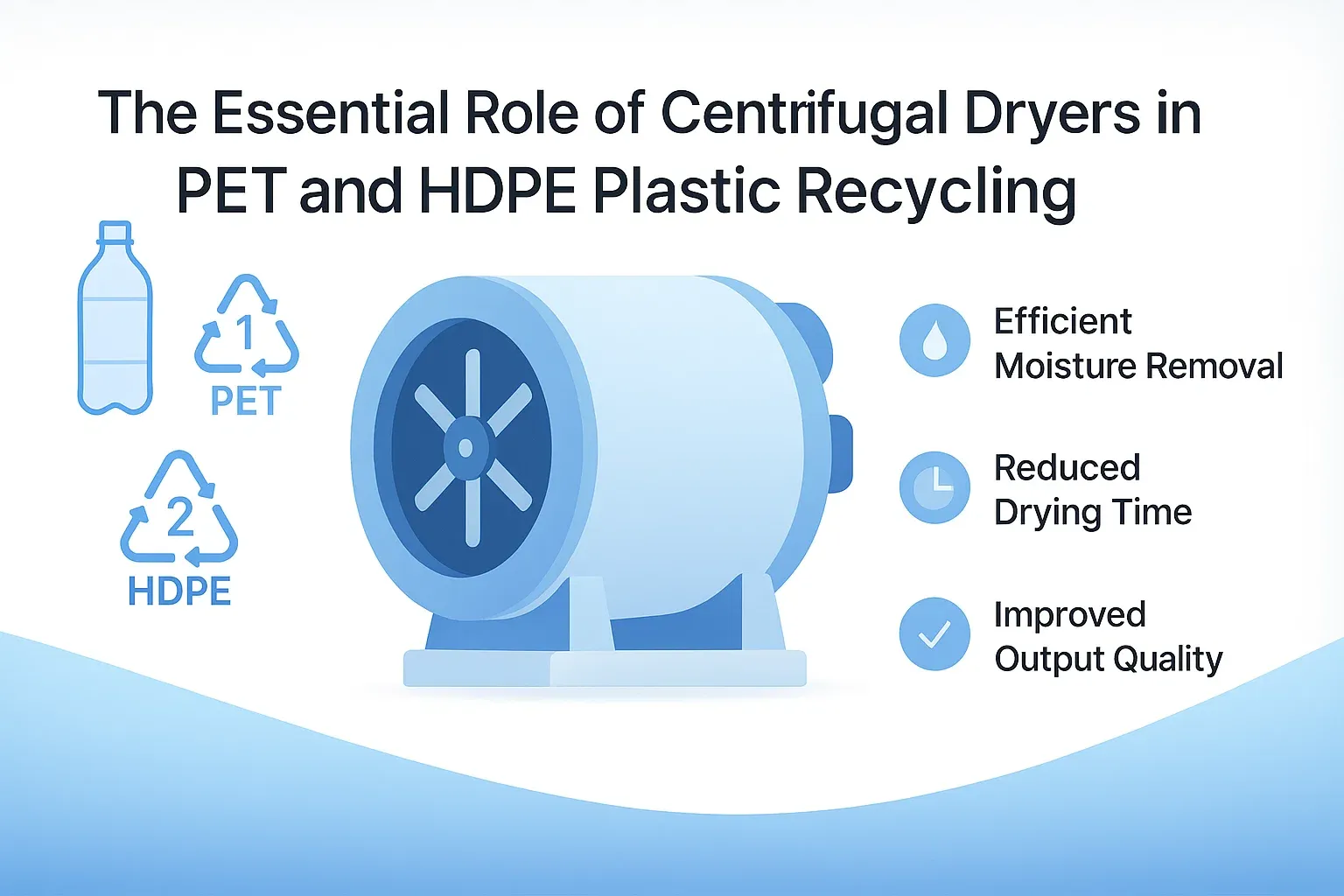

Lås op for hemmelighederne bag overlegen PET- og HDPE-plastgenbrug med en effektiv centrifugaltørrer. Disse essentielle maskiner bruger højhastighedsrotation til grundigt at fjerne fugt fra vaskede plastflager, hvilket bevarer materialets integritet og forbedrer kvaliteten af genbrugsprodukter. Udforsk, hvordan centrifugaltørrere fremmer energieffektivitet, håndterer høj kapacitet og reducerer kontaminering, hvilket gør dem til et omkostningseffektivt og miljøvenligt valg til moderne genbrugsfaciliteter. Lær, hvorfor de er uundværlige til at producere genbrugt PET og HDPE af højeste kvalitet, der er klar til forskellige anvendelser.

Kategorier Nyheder om genbrug

Udgivet den

Naviger nemt gennem plastikkens verden! Denne dybdegående guide gennemgår almindelige plasttyper (PET, HDPE, PVC, LDPE, PP, PS, andet), deres egenskaber, almindelige anvendelser, sikkerhedsovervejelser og hvordan man genbruger dem effektivt. Lær at træffe smartere og miljøvenlige valg.

Kategorier Nyheder om genbrug

Udgivet den

Har du nogensinde spekuleret på, hvordan disse polypropylenposer bliver genbrugt? Dyk ned i vores enkle guide til genbrug af vævede og store PP-poser, de vigtige plastgenbrugsmaskiner, der er involveret, og hvorfor det er et strålende skridt for bæredygtighed.

Kategorier Nyheder om genbrug

Udgivet den

Explore the world of rigid plastics, from the versatile HDPE and heat-resistant PP to the strong PVC and clear PET. This comprehensive guide covers their core properties, common uses in industries like automotive and packaging, and crucial environmental considerations, including recyclability and sustainable practices. Understand the differences and make informed decisions for your material needs.

Kategorier Nyheder om genbrug

Udgivet den

Opdag de vigtigste trin og maskiner, der er involveret i genbrug af PE- og PP-film. Denne omfattende guide dækker indsamling, sortering, rengøring, pelletering og fordelene ved at forvandle plastfilmaffald til en værdifuld ressource for en bæredygtig fremtid.

Kategorier Nyheder om genbrug

Udgivet den

Afvandingsmaskiner er afgørende for plastgenbrug, da de fjerner overskydende vand fra vasket plast for at forberede det til videre forarbejdning. Denne guide udforsker deres rolle, typer (centrifugal, trintørrere, pressemaskiner) og de vigtigste fordele, de tilbyder, såsom reducerede omkostninger og forbedret kvalitet af genbrugsmaterialer.

Kategorier Nyheder om genbrug

Udgivet den

Oplev den fascinerende rejse inden for genbrug af PET-flasker. Fra din genbrugsbeholder til avanceret sortering, vask og granulering, lær hvordan brugte plastikflasker omdannes til værdifuldt RPET til nye produkter som polyesterfibre og emballage, hvilket bidrager til en mere bæredygtig verden.

Kategorier Nyheder om genbrug

Udgivet den

Plastgranulatorer er essentielle maskiner i plastgenbrugsprocessen, der omdanner kasseret plastik til genanvendelige "genformalede" materialer. Vores omfattende guide dækker deres arbejdsprincipper, typer, faktorer der påvirker hastighed, vådgranulering, korrekt brug og afgørende vedligeholdelse for optimal effektivitet.