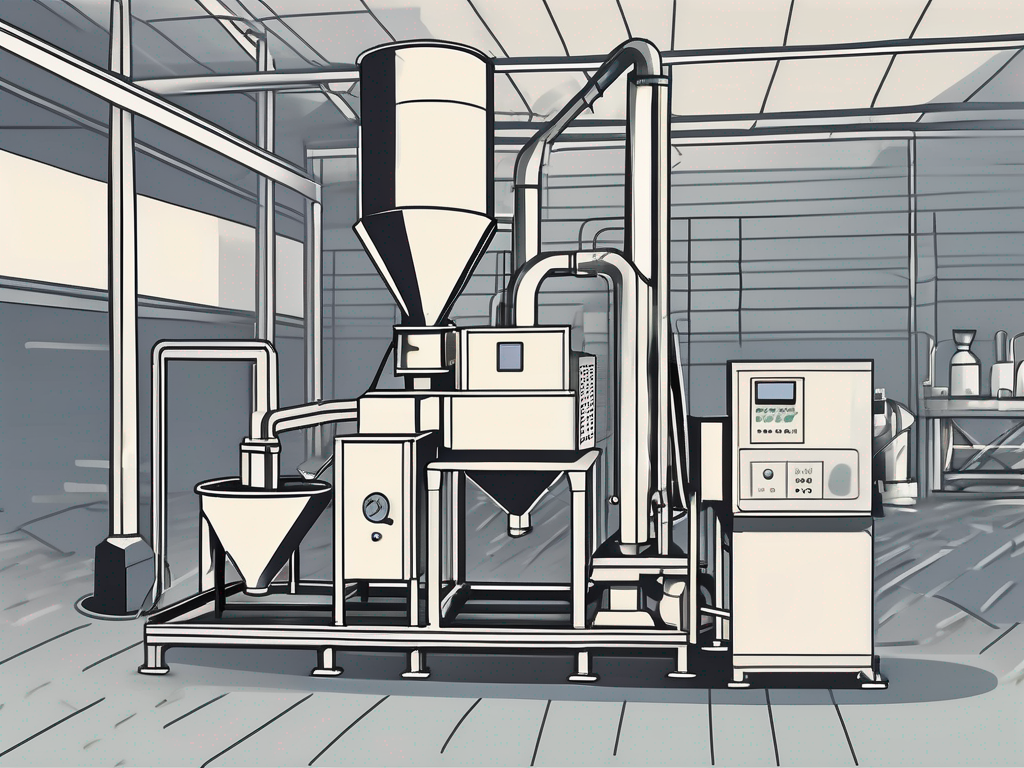

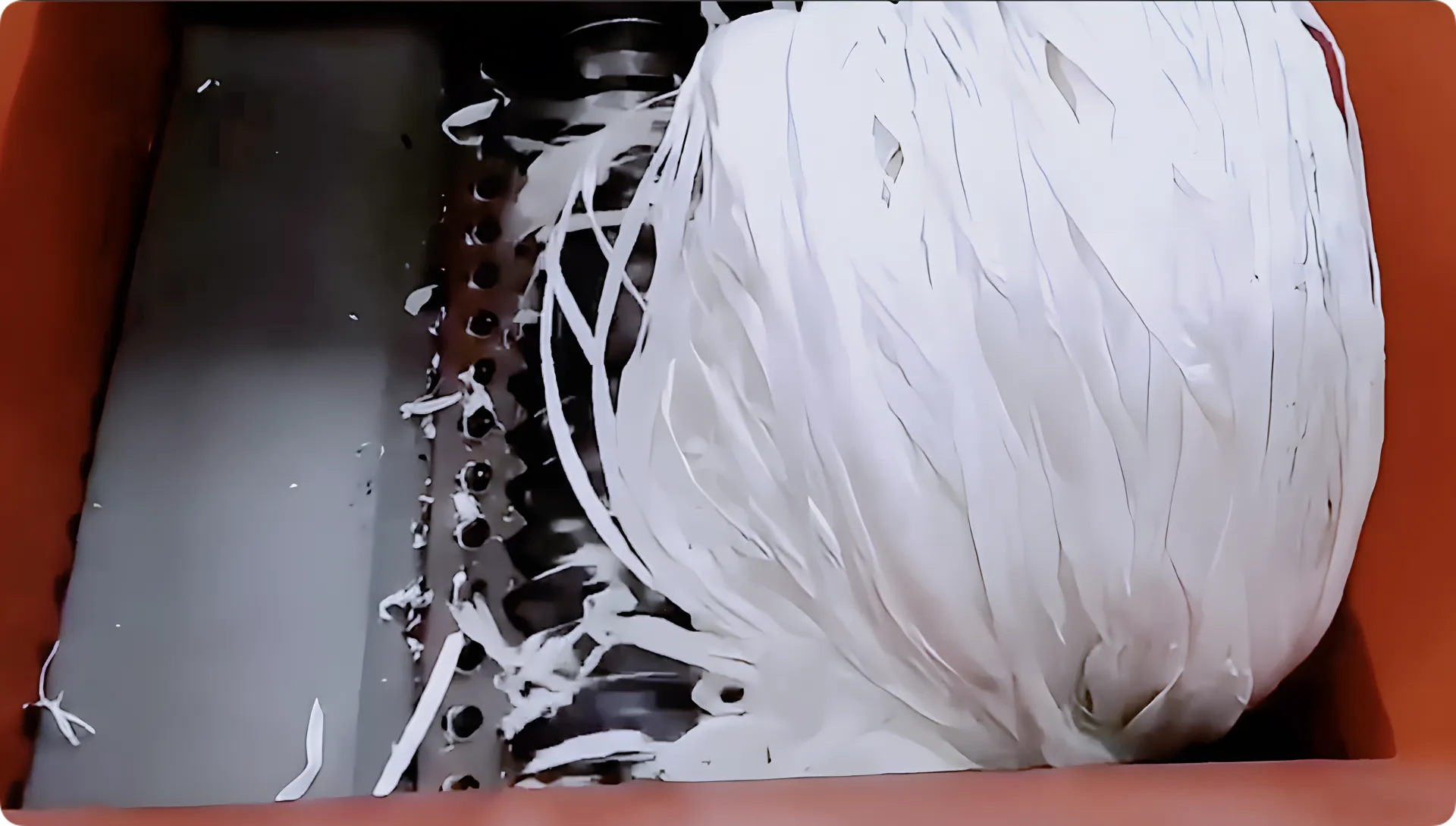

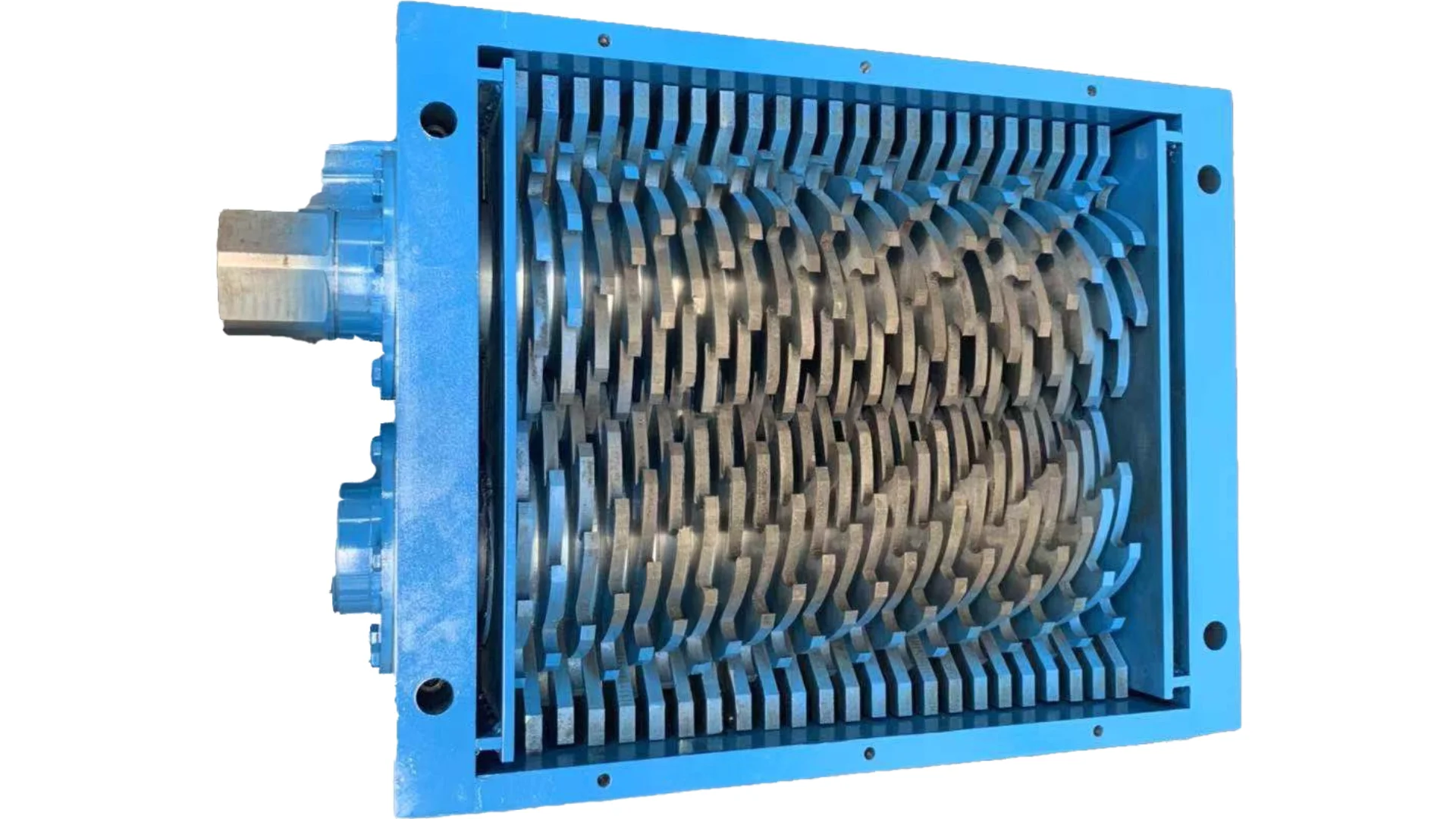

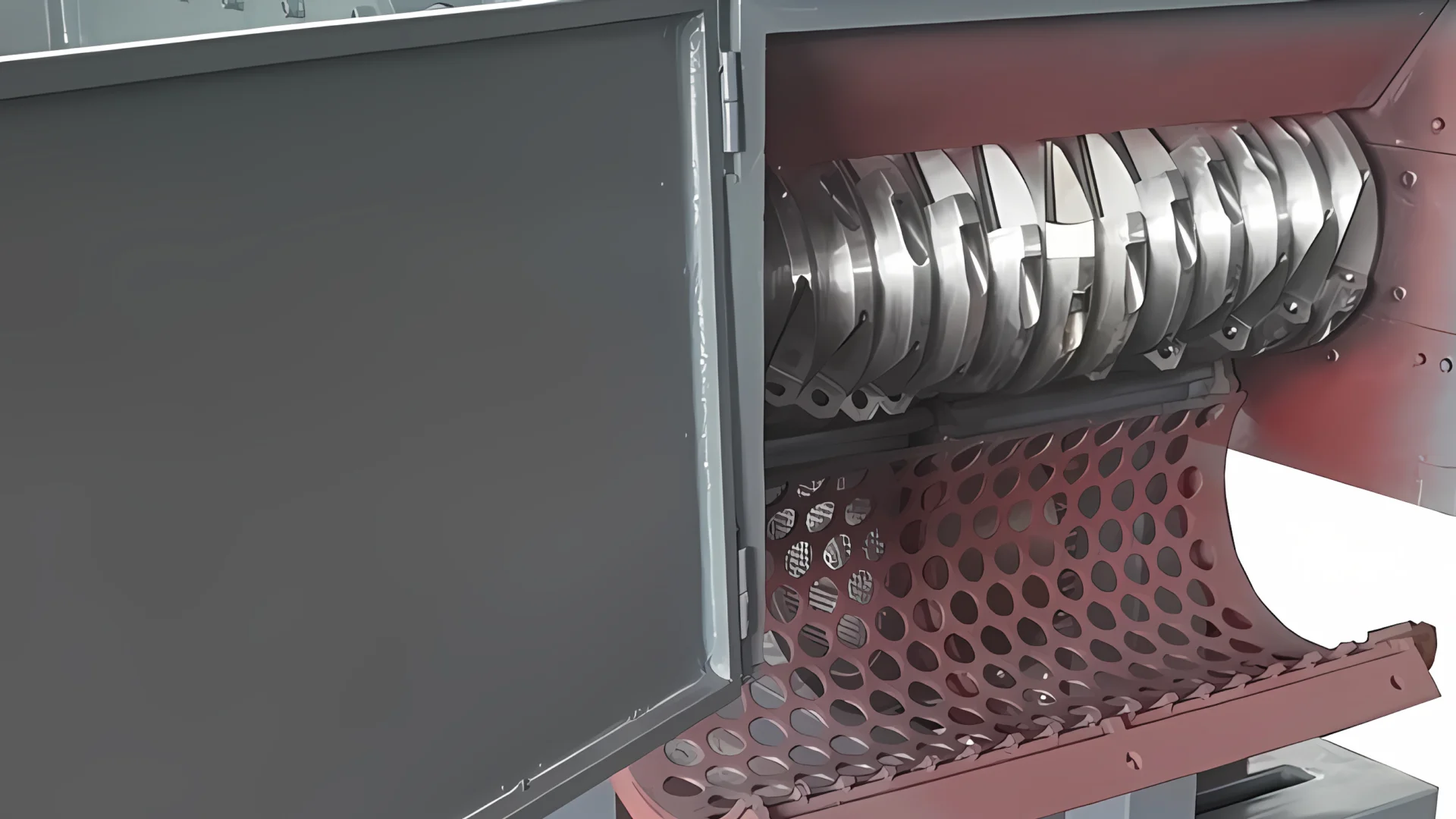

Hvad er nøglekomponenterne i en enkeltskaftet makuleringsmaskine?

Det kan være afgørende for dem, der arbejder i genbrugs- eller affaldshåndteringsindustrien, at forstå forviklingerne ved en enkeltskaftet makuleringsmaskine. Denne type makuleringsmaskine p...