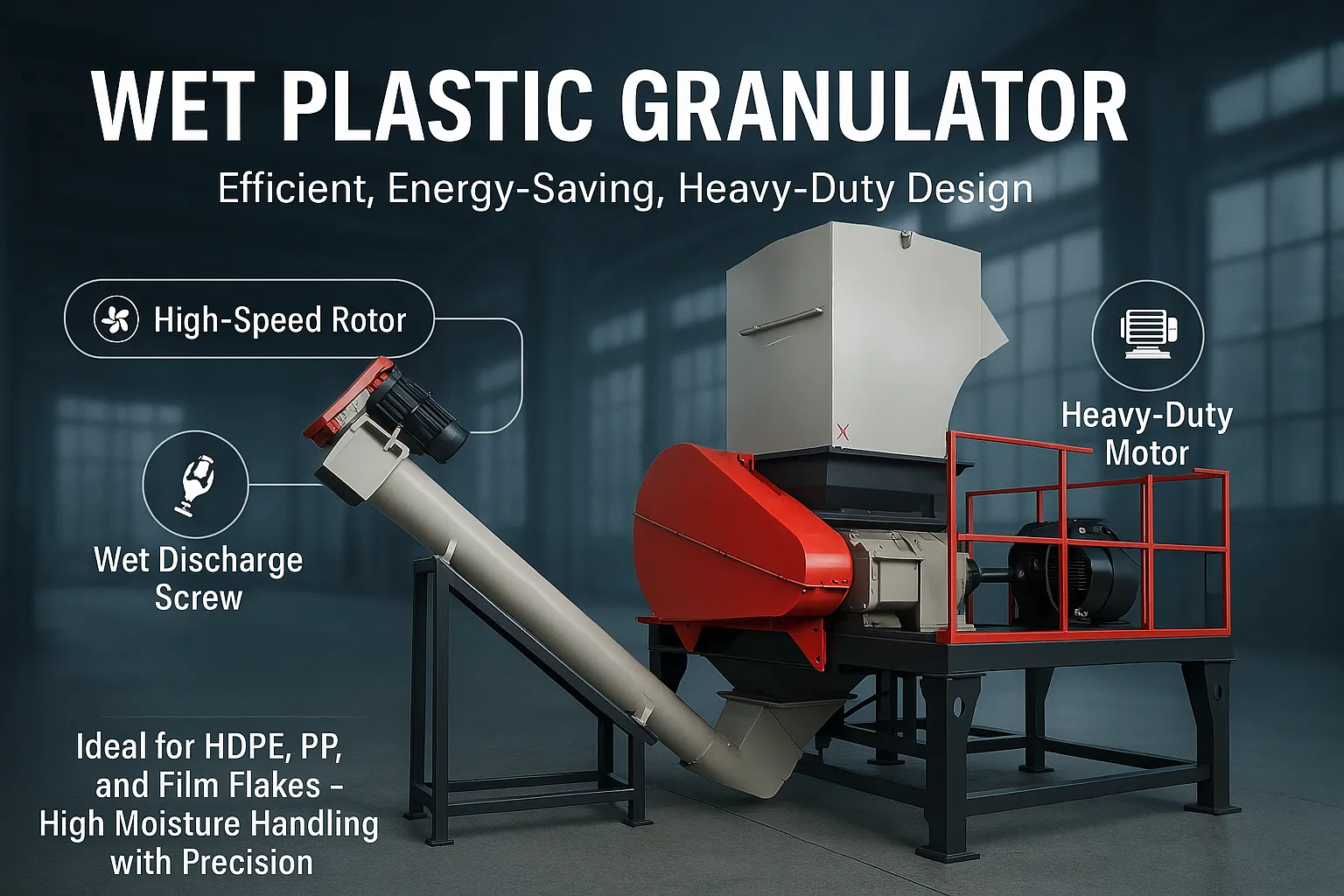

Wet Plastic Granulator: The Advanced Solution for Efficient Plastic Recycling

The escalating global challenge of plastic waste presents not just an environmental concern, but a significant opportunity for innovation. With millions of tons of plastic discarded annually, the need for advanced recycling technologies has never been greater.

Among these innovations, the wet plastic granulator emerges as a specialized and highly effective tool for processing plastic waste. This machine offers a unique and advantageous approach to traditional granulation by integrating water into the process. This incorporation of water not only boosts operational efficiency but also minimizes wear and tear on the machinery, positioning it as a sustainable and increasingly cost-effective solution for modern recycling facilities. Join us as we delve into the distinctive features and benefits of wet plastic granulators and explore how they can significantly enhance your recycling capabilities.

What is a Wet Plastic Granulator?

A wet plastic granulator represents a significant advancement in machinery designed for the efficient shredding and grinding of plastic materials into consistent, small granules. What sets it apart is its innovative use of water throughout the granulation process. Unlike conventional dry granulators that rely solely on mechanical force for cutting, the wet granulator strategically introduces water into the cutting chamber. This addition serves a multifaceted role: it actively cleans the plastic material, provides crucial lubrication for the cutting blades, and effectively cools the entire system.

The result is a smoother, more efficient operation that yields a higher quality output of plastic regrind. Predominantly utilized in plastic recycling plants, these robust machines are capable of processing a diverse range of plastics, from flexible bottles and films to rigid containers, transforming them into valuable, reusable flakes or granules ready for subsequent processing stages.

To learn the difference between a wet plastic shredder and a standard plastic shredder, see our detailed comparison.

Main Features and Advantages

The wet plastic granulator is more than just an upgrade; it’s a significant leap forward in how we approach plastic recycling. Its unique design and features offer a compelling set of advantages:

Hauptmerkmale

- Integrated Water Injection System: A precisely engineered water line strategically sprays a controlled amount of liquid directly into the cutting chamber, significantly enhancing the granulation process through cleaning, lubrication, and cooling.

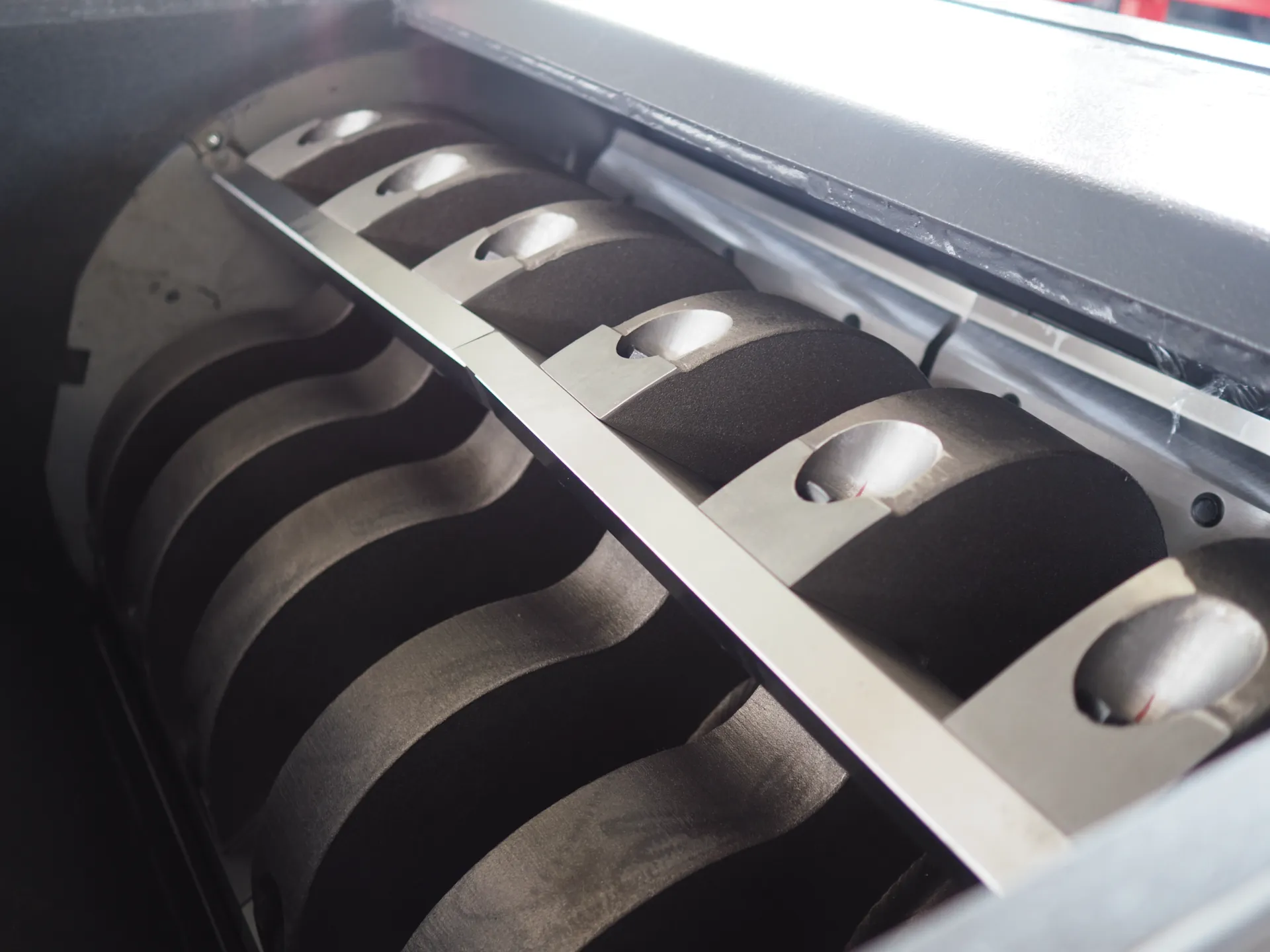

- High-Quality, Durable Blades: Equipped with exceptionally durable knives crafted from high-carbon, high-chromium steel (often utilizing grades like D2 or equivalent), these blades are typically arranged in a highly efficient double-scissor or V-shape configuration to ensure optimal cutting performance and longevity.

- Robust Open Rotor Design: A dynamically balanced open rotor spins at high speeds, typically ranging from 400 to 600 RPM, guaranteeing efficient shredding and the production of consistently sized granules.

Vorteile

- Built-in Pre-Washing Capability: The continuous flow of water actively washes away a significant portion of dirt, dust, labels, and other surface contaminants from the plastic during the granulation process.

- Significantly Reduced Friction and Heat: Water acts as a highly effective lubricant and coolant, drastically minimizing friction between the rotating blades and the plastic material.

- Superior Granule Quality: The combination of consistent cutting action and effective cooling results in the production of uniform, high-quality granules with minimal fines.

Wet Granulator in Action

Anwendungsbereiche

The versatility and efficiency of the wet plastic granulator make it an invaluable asset across a diverse range of industries focused on plastic recycling and material processing. Here are some key sectors where its capabilities truly shine:

Plastic Recycling Plants

As a cornerstone of post-consumer plastic processing, wet granulators are ideally suited for transforming collected plastics into high-quality reusable granules.

Verpackungsindustrie

Provides an efficient solution for converting in-house scrap plastic generated during production processes back into valuable raw material.

Manufacturing Sector

The consistent and high-quality granules serve as an excellent feedstock for various manufacturing processes.

Technische Parameter

| Modell | Drehzahl (U/min) | Drehdurchmesser (mm) | Hauptmotorleistung (kW) | Messermaterial | Kapazität (kg/h) |

|---|---|---|---|---|---|

| ERMW-500 | 550 | Φ500 | 45 kW | SKD11 | 500-800 |

| ERMW-600 | 500 | Φ600 | 55 kW | SKD11 | 800-1500 |

| ERMW-700 | 428 | Φ700 | 90 kW | SKD11 | 1500-2000 |

| ERMW-800 | 370 | Φ800 | 110 kW | SKD11 | 2000-2500 |

Why Choose Our Wet Plastic Granulator?

- Anpassbare Konfigurationen: We offer tailored machine configurations to precisely match your specific material processing needs.

- Superior Build Quality: Constructed using only top-tier components for exceptional long-term reliability.

- Energy-Saving Design: Engineered for optimal efficiency to help reduce operational costs.

- Expert Support Team: Comprehensive, hands-on guidance from installation to ongoing maintenance.

Contact Us Now!

Ready to revolutionize your plastic recycling operations? The wet plastic granulator represents more than just a piece of machinery—it’s a strategic investment in sustainability and business growth.