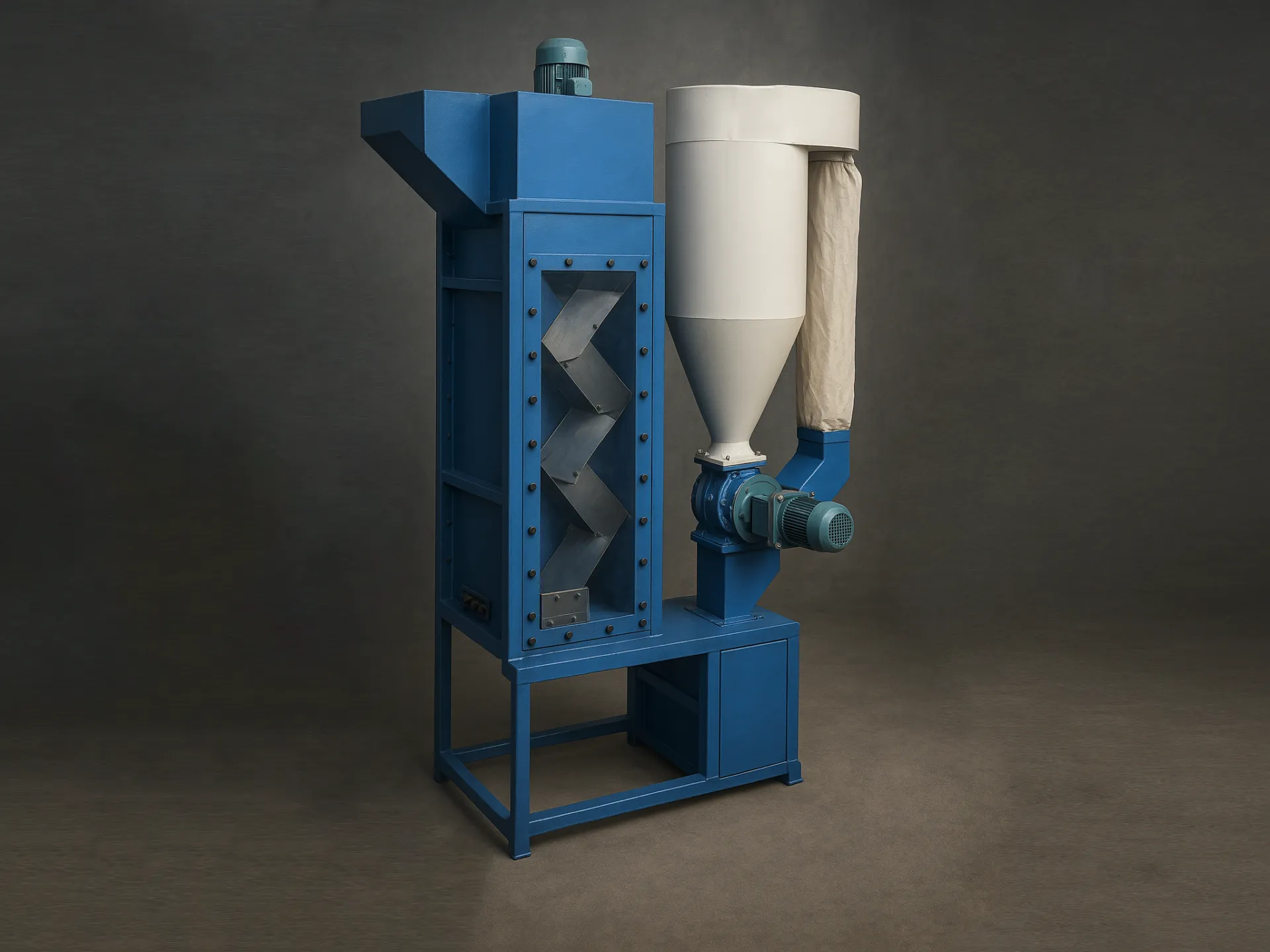

Erzielen Sie eine hervorragende Materialtrennung mit dem fortschrittlichen Zickzack-Luftklassierer

Einführung der Zickzack-Luftklassierer, eine innovative Lösung, die sorgfältig für höchste Präzision bei der Materialtrennung entwickelt wurde. Dieses hochmoderne System zeichnet sich durch die effiziente Trennung leichterer Verunreinigungen von schwereren Materialien aus und hat sich in zahlreichen Branchen als unverzichtbarer Bestandteil etabliert, insbesondere im Kunststoffrecycling und in der umfassenden Abfallwirtschaft.

Die innovative Wissenschaft der luftbetriebenen Trennung

Der Zig-Zag-Luftklassierer nutzt eine hochentwickelte luftbasierte Trenntechnik, um außergewöhnliche Ergebnisse zu erzielen:

- Materialeinführung: Ein heterogener Materialstrom wird nahtlos in die fachmännisch konstruierte Kammer des Klassifizierers eingeführt.

- Aktivierung der Luftsäule: In der Trennkammer wird eine präzise kontrollierte und kräftige Säule aufsteigender Luft erzeugt.

- Der Trennungsprozess enthüllt:

- Leichtere Materialien steigen auf: Gegenstände mit geringerer Dichte werden vom aufsteigenden Luftstrom mühelos angehoben und treten effizient durch den dafür vorgesehenen oberen Auslass aus.

- Schwerere Materialien steigen ab: Umgekehrt überwinden dichtere Gegenstände den aufwärts gerichteten Luftstrom, sinken ab und werden zuverlässig durch den unteren Auslass ausgetragen.

Dieses sorgfältig konzipierte Verfahren garantiert einen zuverlässigen und äußerst effizienten Trennprozess, der auf den grundlegenden Unterschieden in der Materialdichte beruht.

Hauptmerkmale und entscheidende Vorteile

- Unübertroffene Trenneffizienz: Erreichen Sie eine punktgenaue Sortierung der Materialien durch die intelligente Anwendung der Luftdynamik und verbessern Sie so die Gesamtverarbeitungseffizienz und Materialreinheit erheblich.

- Breite Anwendungsvielfalt: Perfekt geeignet für eine große Bandbreite an Materialien, darunter verschiedene Kunststoffarten, diverse Metalle und zahlreiche andere wertvolle Wertstoffe.

- Energiebewusster Betrieb: Entwickelt, um den Energieverbrauch zu minimieren und gleichzeitig stets optimale Leistung zu liefern, was direkt zu erheblichen Kosteneinsparungen beiträgt und Initiativen zur ökologischen Nachhaltigkeit unterstützt.

- Platzsparendes und anpassungsfähiges Design: Verfügt über eine kompakte Stellfläche, wodurch wertvoller Betriebsraum gespart wird, gepaart mit modularen Komponenten, die eine nahtlose Integration in vorhandene Verarbeitungslinien ermöglichen und mühelose Skalierbarkeit für zukünftiges Wachstum bieten.

Nahtlose Integration und umfassender Support

- Maßgeschneiderte Lösungen für Ihre Bedürfnisse: Vollständig konfigurierbar, um Ihre spezifischen Betriebsanforderungen genau zu erfüllen und eine mühelose Integration in eine Vielzahl von Verarbeitungsumgebungen zu gewährleisten.

- Fachmännische Inbetriebnahme und gründliche Einweisung: Profitieren Sie von professionellen Einrichtungsservices durch unsere erfahrenen Techniker sowie umfassenden Schulungsprogrammen für Ihr Betriebspersonal, die maximale Systemeffektivität und Benutzerkompetenz garantieren.

- Spezieller After-Sales-Support: Profitieren Sie von kontinuierlicher Wartung und reaktionsschnellen Supportservices, die eine dauerhaft optimale Leistung und längere Lebensdauer Ihrer wertvollen Geräte gewährleisten.

Erhöhen Sie Ihre Materialsortierleistung mit dem Zig-Zag-Luftklassierer – hier treffen modernste Innovation und außergewöhnliche Effizienz aufeinander. Für detaillierte Informationen, die speziell auf Ihre individuellen Anwendungsanforderungen zugeschnitten sind, kontaktieren Sie uns gerne. Kontaktieren Sie uns noch heute.

Technische Spezifikationen

| Gebläsemotor: | 5,5 KW |

| Drehventilmotor: | 1,5 KW |

| Drehventil Durchmesser: | ⌀270 mm |

| Drehgeschwindigkeit des Drehventils: | 50 U/min |

| Zyklonabscheider Volumen: | 600 Liter |

Bilder

Fazit: Die Zukunft der Materialtrennung ist da

Der Zig-Zag-Luftklassierer überwindet die Grenzen herkömmlicher Sortierlösungen. Er stellt eine echte Innovation dar, die die Effizienz deutlich steigert, Abfall minimiert und ein breites Anwendungsspektrum bietet. Von der Revolutionierung der Kunststoffindustrie bis zur Optimierung von Papierrecyclingprozessen – dieser Klassierer ist ein echter Wendepunkt in der Materialtrennung. Sein durchdachtes, kompaktes Design und der bemerkenswert geringe Wartungsaufwand machen ihn zur ersten Wahl für zukunftsorientierte Unternehmen, die ihre Betriebsabläufe optimieren möchten.

Garantie und Support

Für alle unsere modernen Recyclingmaschinen gilt eine umfassende Garantie, die Ihnen absolute Sicherheit bietet. Wir bieten außerdem professionelle Installationspakete an. Unsere erfahrenen Techniker kommen zu Ihnen vor Ort und begleiten Sie fachkundig durch die einzelnen Schritte des Installationsprozesses.

Alle unsere Hochleistungsprodukte können vollständig individuell angepasst werden, um genau auf die spezifischen Kundenanforderungen abgestimmt zu sein und so eine perfekte Passform für Ihre individuellen Bedürfnisse zu gewährleisten.

ANFRAGEN

Um die aktuellsten Preisinformationen und detaillierte Lieferzeiten zu erhalten, senden Sie uns bitte eine Nachricht über das unten stehende praktische Formular.

[…] Zyklonabscheider […]

[…] Zyklonabscheider sind im Kunststoffrecycling von entscheidender Bedeutung, da sie Materialien effizient sortieren und reinigen, indem sie Unterschiede in Partikeldichte, -größe und Luftströmungsdynamik ausnutzen. So werden sie an branchenspezifische Anforderungen angepasst: […]