-2.webp)

-3.webp?fit=crop&ar=4:3&auto=format,compress&fm=webp)

-4.webp?fit=crop&ar=4:3&auto=format,compress&fm=webp)

-5.webp?fit=crop&ar=4:3&auto=format,compress&fm=webp)

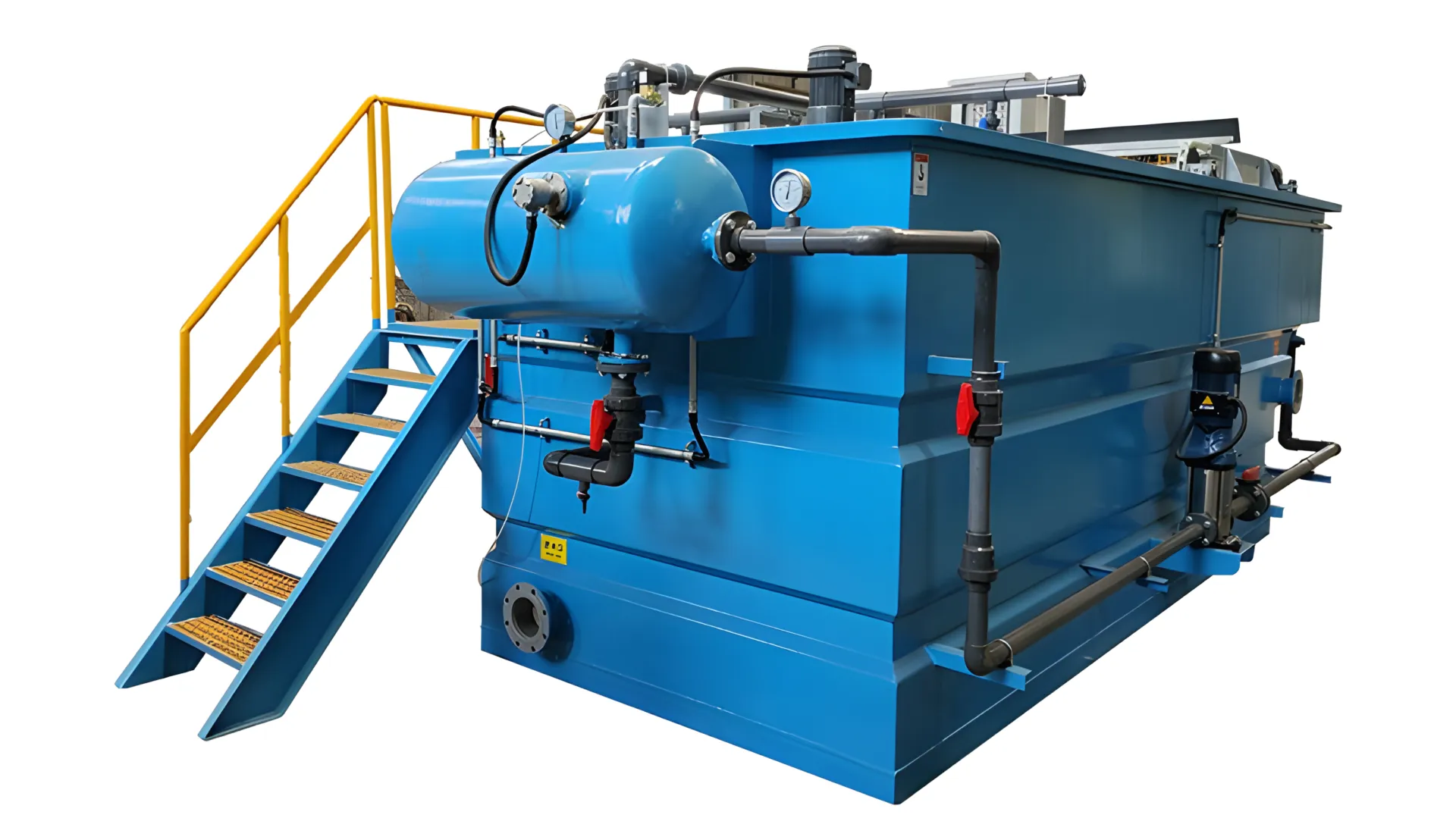

Working Principle

Dissolved Air Flotation Process

The Dissolved Air Flotation (DAF) system is designed to effectively remove suspended solids (TSS), biochemical oxygen demand (BOD₅), and oils and greases (O&G) from wastewater. This process utilizes a dissolved aqueous solution of water, which is enriched with air injected into the recirculating stream of DAF effluent under pressure.

Once the recycle stream mixes with incoming wastewater in the internal contact chamber, air bubbles form. These bubbles lift contaminants to the surface, creating a floating layer that is skimmed off by a surface skimmer for further processing. This ensures high efficiency in wastewater treatment and sludge management.

Features

- Innovative Structural Design: Exponential increase in settlement area, enhancing capacity.

- Inclined Lamella Plates: Promotes re-agglomeration for better particle settlement.

- Lamella Clarifier: Ensures optimal laminar flow for improved precipitation.

- High Sludge Concentration: Results in efficient sludge sinking.

- Stable Sewage Removal: Prevents sludge coverage during the process.

- Space-Saving: Optimized design significantly reduces floor space requirements.

- Durable Materials: PVC inclined plates provide superior strength and resistance to collapse.

- Easy Maintenance: Plates are removable and easy to maintain.

- Back-Washing Machine: Prevents sludge build-up on inclined plates, ensuring uninterrupted performance.

Advantages

-

Stable and Low-Noise Operation: Ensures consistent performance with minimal noise.

-

Enhanced Removal Efficiency: High-density air bubbles increase adsorption and improve the removal of suspended solids.

-

User-Friendly Control System: Simple, reliable, and easy to maintain.

-

Compact Multi-Phase Flow Pump: Replaces traditional components like pressure pumps and air compressors, reducing footprint.

-

High Efficiency: Yosun DAF offers superior flotation efficiency compared to conventional systems.

-

Effective Micro-Bubble Generation: Produces abundant 20µm bubbles for superior water treatment.

-

Multilayer Solid Outlet: Enhances the efficiency of water processing.

-

Energy Efficiency: Operates under low tension, achieving air flotation efficiency of up to 99%.

Applications

The DAF system is ideal for industries requiring advanced water treatment, such as municipal wastewater plants, food processing facilities, and oil refineries. Its compact, efficient design ensures compliance with stringent environmental regulations while maintaining operational efficiency.

DAF Model Selection Table

| Model | Capacity (m³/h) | Inlet | Outlet | Sludge | Vent | L/L1 (m) | W/W1 (m) | H/H1 (m) |

|---|---|---|---|---|---|---|---|---|

| DAF-002 | 2 | DN50 | DN50 | DN100 | DN100 | 3.4/2.5 | 3.4/1.16 | 2.2/1.7 |

| DAF-003 | 3 | DN50 | DN50 | DN100 | DN100 | 3.7/2.8 | 2.4/1.16 | 2.2/1.7 |

| DAF-005 | 5 | DN80 | DN80 | DN100 | DN80 | 4.0/3.0 | 2.4/1.16 | 2.2/1.7 |

| DAF-010 | 10 | DN100 | DN100 | DN100 | DN100 | 4.65/3.8 | 2.7/1.36 | 2.4/1.9 |

Warranty & Installation

Each recycling machine includes a 1-year limited warranty. We provide installation services, with our engineers visiting your site to assist with the setup process. Arrangements for regular maintenance crews and operational consultants can also be made.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.

.webp?fit=crop&ar=4:3&auto=format,compress&fm=webp)