In today’s world, plastic waste management has become a critical environmental challenge. As industries seek sustainable solutions, double-shaft plastic shredders have emerged as a game-changing technology. This article explores the features, benefits, and applications of these powerful machines in recycling and waste reduction.

What is a Double-Shaft Plastic Shredder?

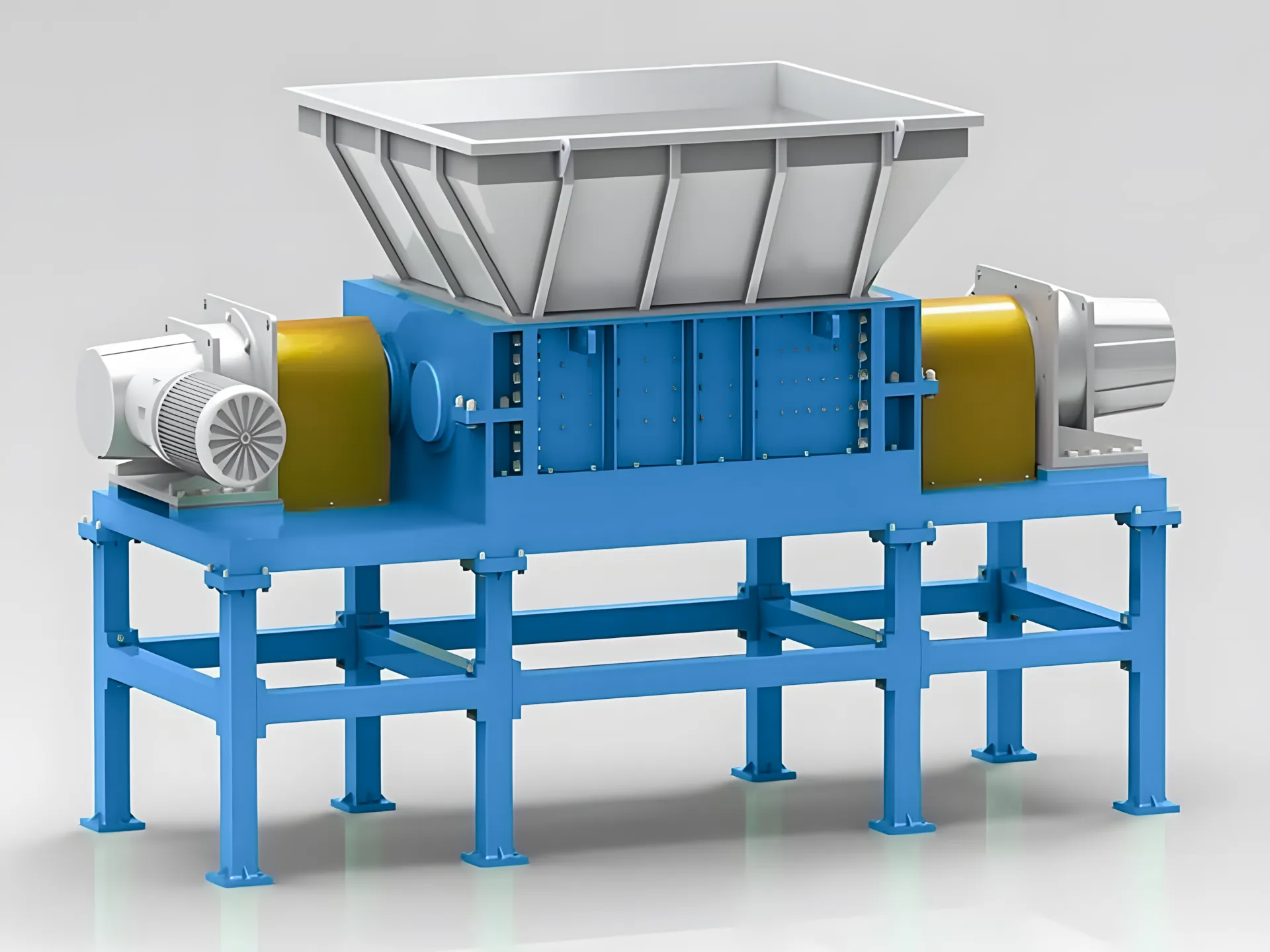

A double-shaft plastic shredder is an industrial machine designed to process large volumes of plastic waste efficiently. It features two counter-rotating shafts equipped with cutting blades, capable of handling a wide range of plastic materials, including PVC, PET, HDPE, and more.

Key Features and Advantages

- High-Efficiency Shredding: The dual-shaft design ensures even and efficient shredding of materials.

- Versatility: Capable of processing various types of plastics and other materials.

- Robust Construction: Built with high-alloy steel (42CrMo) for durability and longevity.

- Safety Features: Equipped with emergency stop buttons, safety guards, and overload protection.

- Auto-Reverse System: Automatically reverses rotor direction when overloaded or jammed.

- Optional Pusher Ram: Available for processing hollow and oversized materials.

| Model | SJ400-800 | SJ400-1200 | SJ450-800 | SJ450-1200 |

|---|---|---|---|---|

| Hydraulic motor power | 2×22kW | 2×30kW | 2×30kW | 2×45kW |

| Number of Blades | 16/26 | 24/40 | 16/26 | 24/40 |

| Approx.Capacity | 1500kg/h | 2500kg/h | 3000kg/h | 4000kg/h |

| Rotating speed(rpm/min) | 25/35 RPM | 25/35 RPM | 18/28 RPM | 18/28 RPM |

Single-shaft shredders to better handle solid, thick pieces such as plastic purging, runners, pallets, and even wood, branches, and bones.

Double-shaft shredders use shear blades to cut the plastic material and are better suited for handling bulk volumes of hollow, light-weight plastics such as PE films, PP tubes, HDPE drums, and even rubber tires, automotive parts, and electronic waste.

Applications in Various Industries

Double-shaft shredders find applications across multiple sectors:

- Plastic Recycling: Processing waste plastic products into small particles for further treatment.

- Wood Processing: Crushing wood waste for biomass fuel production.

- Electronic Waste Management: Handling discarded electronics for valuable metal extraction.

- General Recycling: Processing diverse materials like tires, scrap steel, and waste fabrics.

Environmental and Economic Benefits

- Waste Reduction: Significantly decreases the volume of plastic waste sent to landfills.

- Cost-Effective: Reduces transportation costs and landfill fees for businesses.

- Energy Efficiency: Consumes less energy compared to other shredding methods.

- Circular Economy: Supports recycling efforts and promotes sustainable resource use.

Single-Shaft vs. Double-Shaft Shredders

While both types have their merits, double-shaft shredders excel in:

- Processing denser and harder materials

- Achieving higher throughput rates

- Producing more uniform output

Single-shaft shredders, however, are more suitable for softer materials and are generally more cost-effective.

Conclusion

Double-shaft plastic shredders represent a significant advancement in waste management technology. By investing in these machines, businesses can enhance their recycling capabilities, reduce environmental impact, and potentially save on operational costs. As we move towards a more sustainable future, technologies like double-shaft shredders will play a crucial role in managing our plastic waste effectively.

Warranty

All recycling machines come with a 1 year limited warranty.

INQUIRIES

To get the latest prices and lead times, send us a message using the form below.