Introduction to Drying Systems

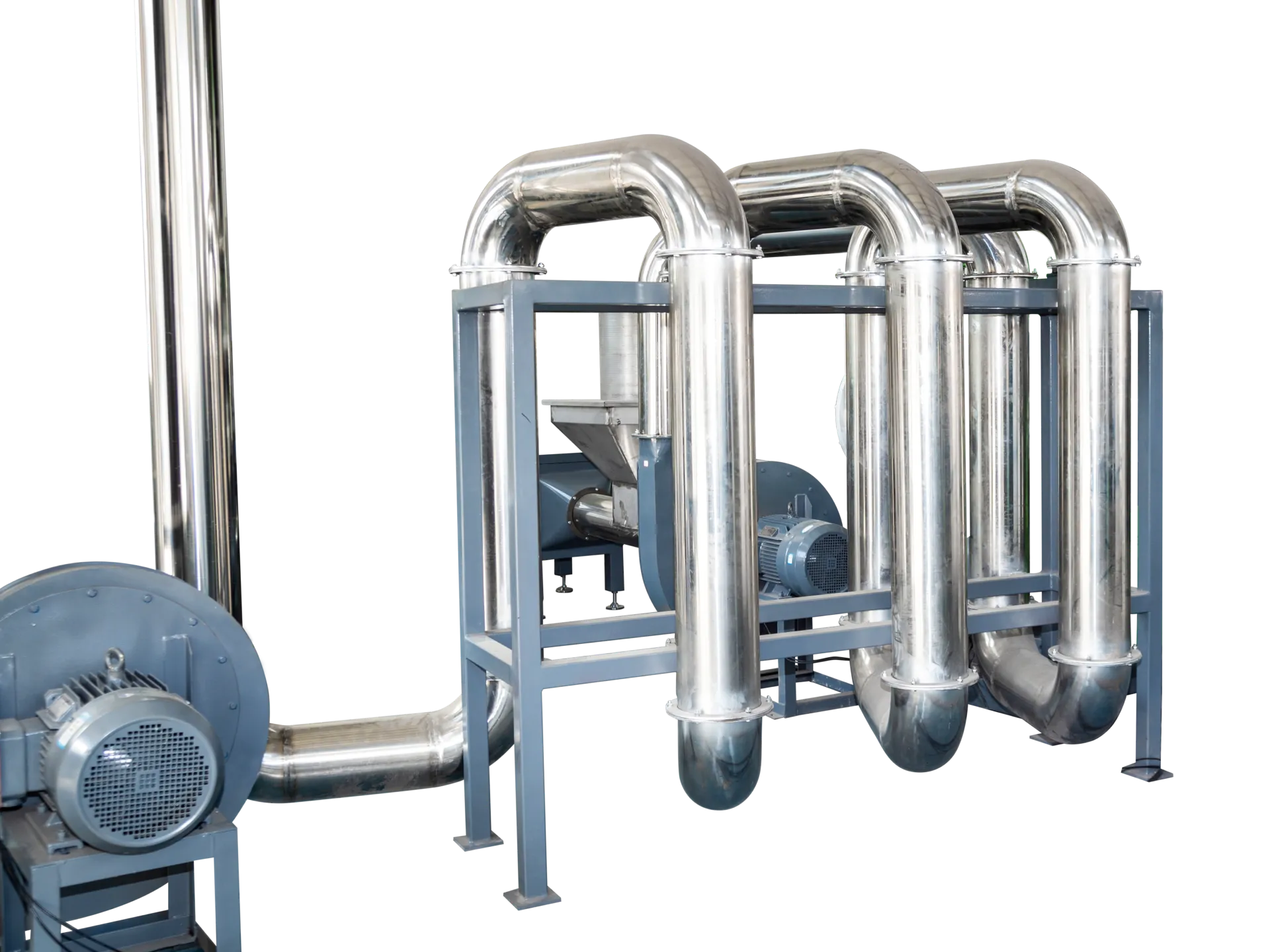

Drying systems are a critical component in the plastic recycling process. They ensure that plastic materials are free from moisture before they are processed further. Moisture can negatively affect the quality of recycled plastic, leading to defects in the final product. Drying systems help maintain the integrity and performance of recycled plastics.

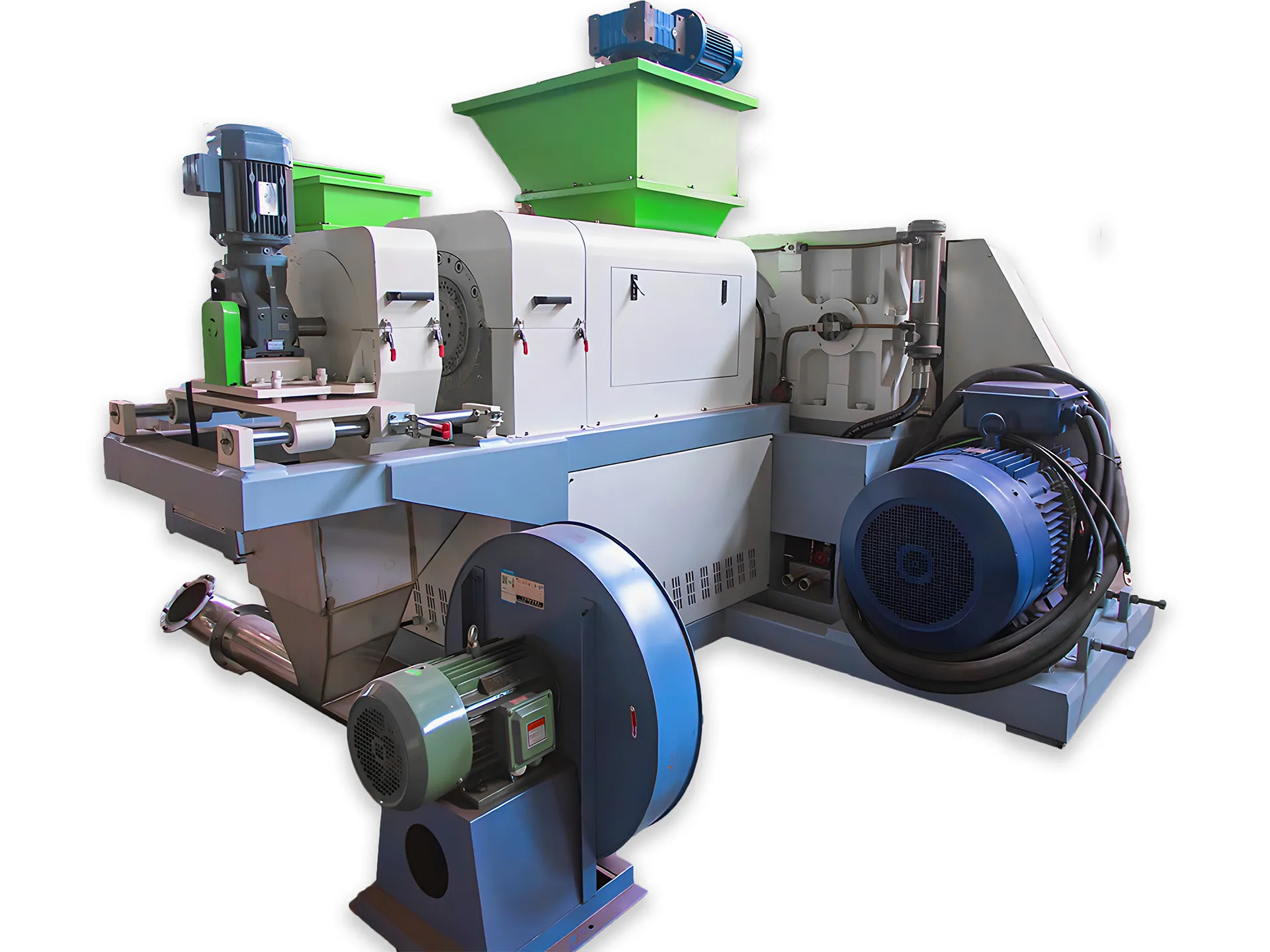

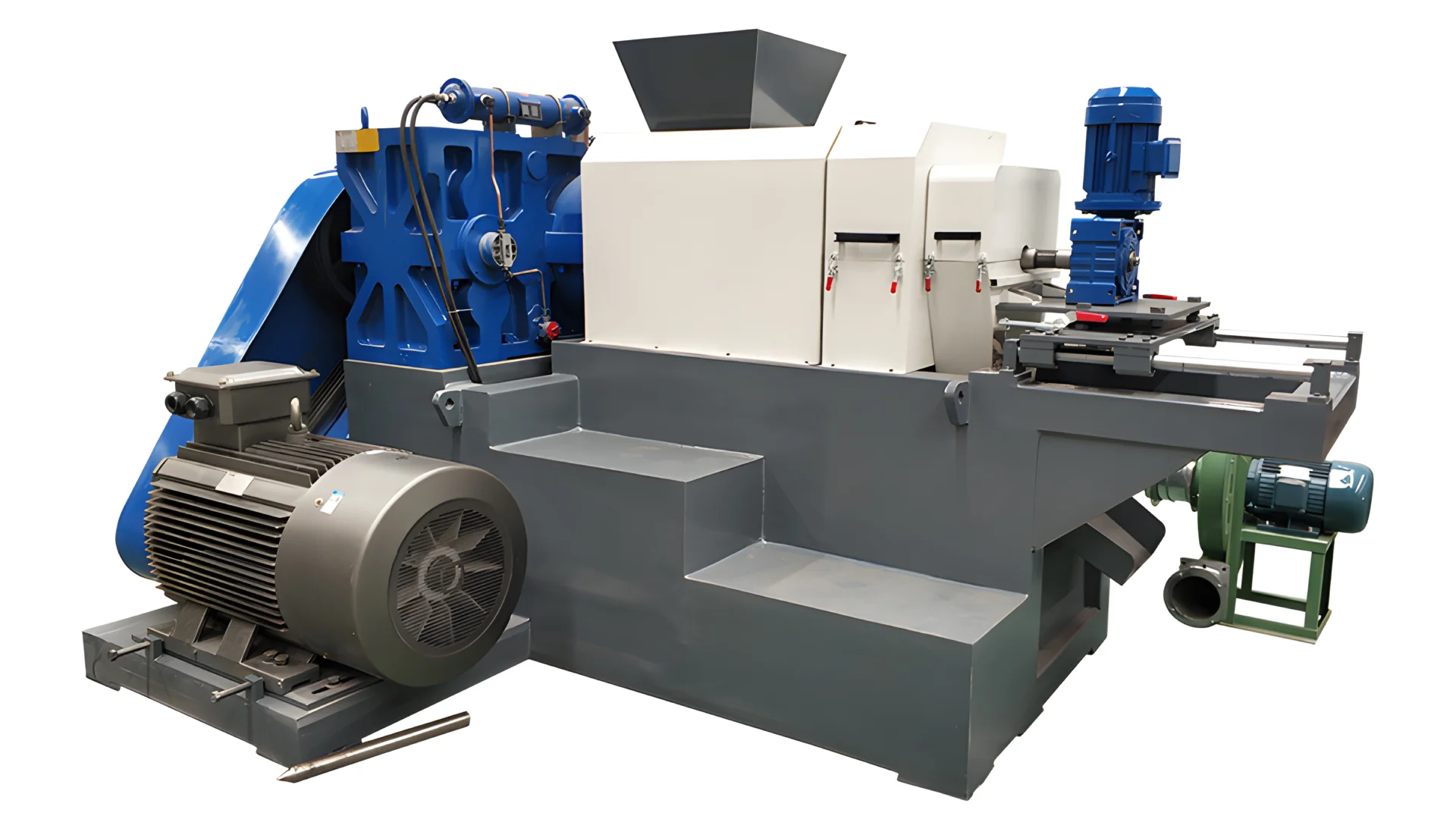

Key Features of Drying Systems

- Efficient Moisture Removal: Advanced drying systems are designed to remove moisture quickly and effectively, ensuring optimal material quality.

- Energy Efficiency: Modern drying systems are built to consume less energy, reducing operational costs and environmental impact.

- Customizable Solutions: Drying systems can be tailored to meet the specific needs of different types of plastic materials and recycling processes.

- Durability: Constructed with high-quality materials, these systems are built to withstand the rigors of continuous operation.

- User-Friendly Controls: Intuitive interfaces make it easy for operators to monitor and adjust drying parameters.

Benefits of Using Drying Systems

Investing in a high-quality drying system for your plastic recycling operation offers several benefits:

- Improved product quality and consistency.

- Reduced waste and increased efficiency.

- Lower energy consumption and operational costs.

- Enhanced durability and longevity of recycled plastic products.

Data-Driven Drying: Optimize Your Process with Intelligent Systems

Boost Productivity, Save Resources: The Power of Efficient Drying

Quality Control Champions: Precision Drying for Consistent Results

Sustainability Champions: Eco-Friendly Drying Systems for a Greener Future