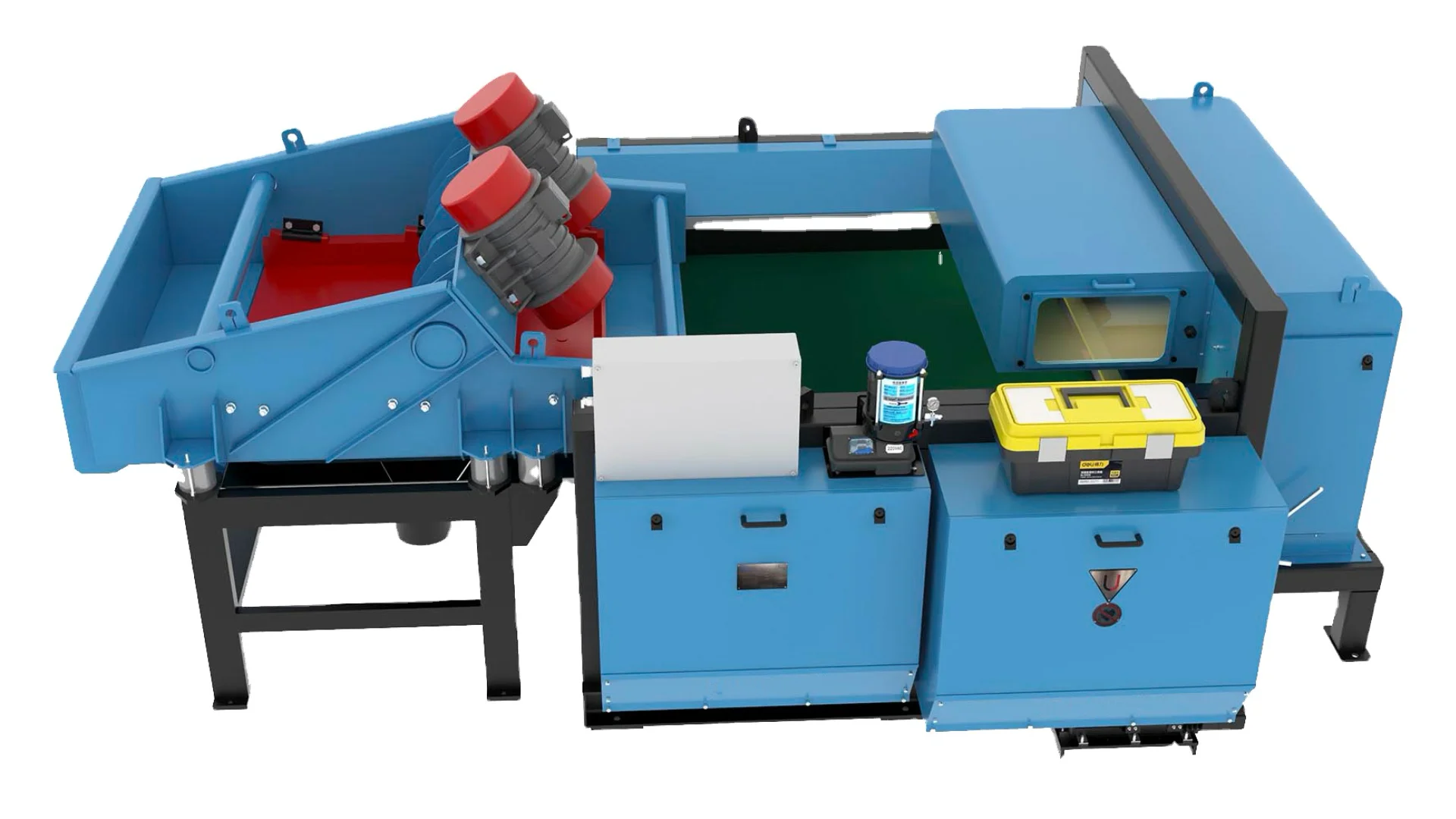

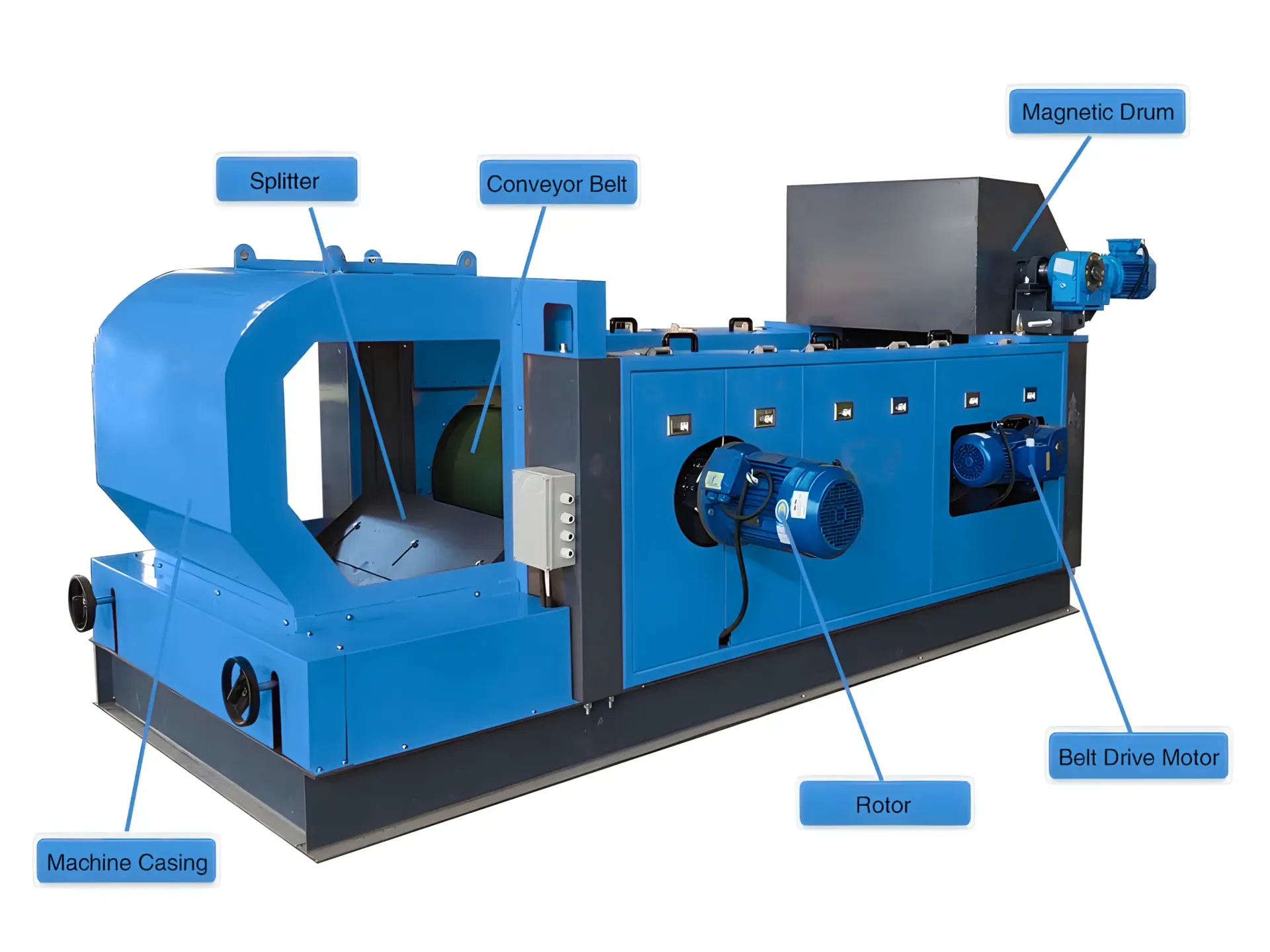

Eddy Current Magnetic Separator

Efficiently recover non-ferrous metals with advanced Eddy Current Separator. Our innovative eccentric pole system ensures maximum adjustability and recovery, making it ideal for various recycling operations.

Technical Parameters

- Roller Diameter: 280mm

- Belt Width: 300mm

- Power Supply: 4.5 kW

- Magnetic Field Strength: Adjustable for high recovery rates

- High Separation Efficiency: Achieves up to 96% recovery of non-ferrous metals

- Machine Dimensions: Customizable for different facilities

Key Features

-

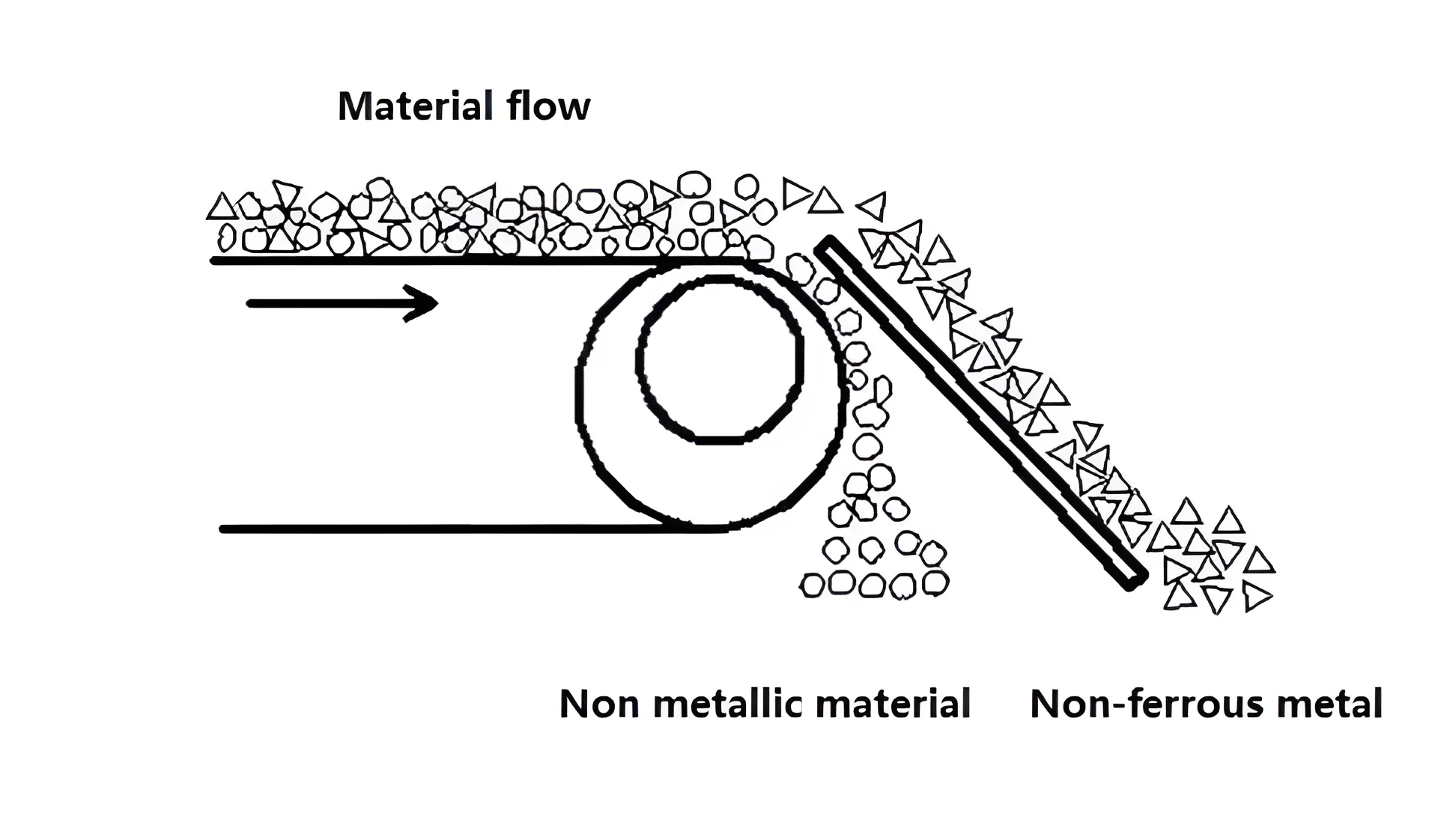

Eccentric and Concentric Pole Systems

Adaptable to different recycling needs, the eccentric pole system maximizes recovery, while the concentric pole system is ideal for fine fractions and materials with less magnetic dust.

-

High Separation Efficiency

Effectively separates non-ferrous metals with precision, ensuring maximum purity and output quality.

-

Two-Stage Separation

Optional two-stage separation process for optimized material recovery, particularly in demanding recycling environments.

-

Low Maintenance and Energy Efficient

The machine is designed for easy operation and minimal maintenance, with low energy consumption for long-term savings.

Specifications

| Model | Belt Width (mm) | Roller Diameter (mm) | Belt Speed (m/s) | Magnetic Roller Motor Power (kW) | Belt Motor Power (kW) | Weight (kg) | Length A (mm) | Width B (mm) | Height C (mm) |

|---|---|---|---|---|---|---|---|---|---|

| SES-300 | 300 | 280 | 0~2.5 | 2.2 | 0.75 | 760 | 1940 | 1472 | 1075 |

Applications

Aluminum Recycling

Efficient separation of aluminum from waste streams.

Shredder Material

Processes shredder material for effective metal recovery.

Electronic Scrap (WEEE)

Recovers valuable non-ferrous metals from electronic waste.

Glass and Plastics

Separation of non-ferrous metals in glass, plastic, and wood recycling applications.

More