Working Principle

1. Feeding and Crushing

2. Hydraulic Compression

- The crushed foam pieces are transferred to a compression chamber.

- A hydraulic system applies significant pressure to compress the foam, effectively reducing its volume by up to 50:1.

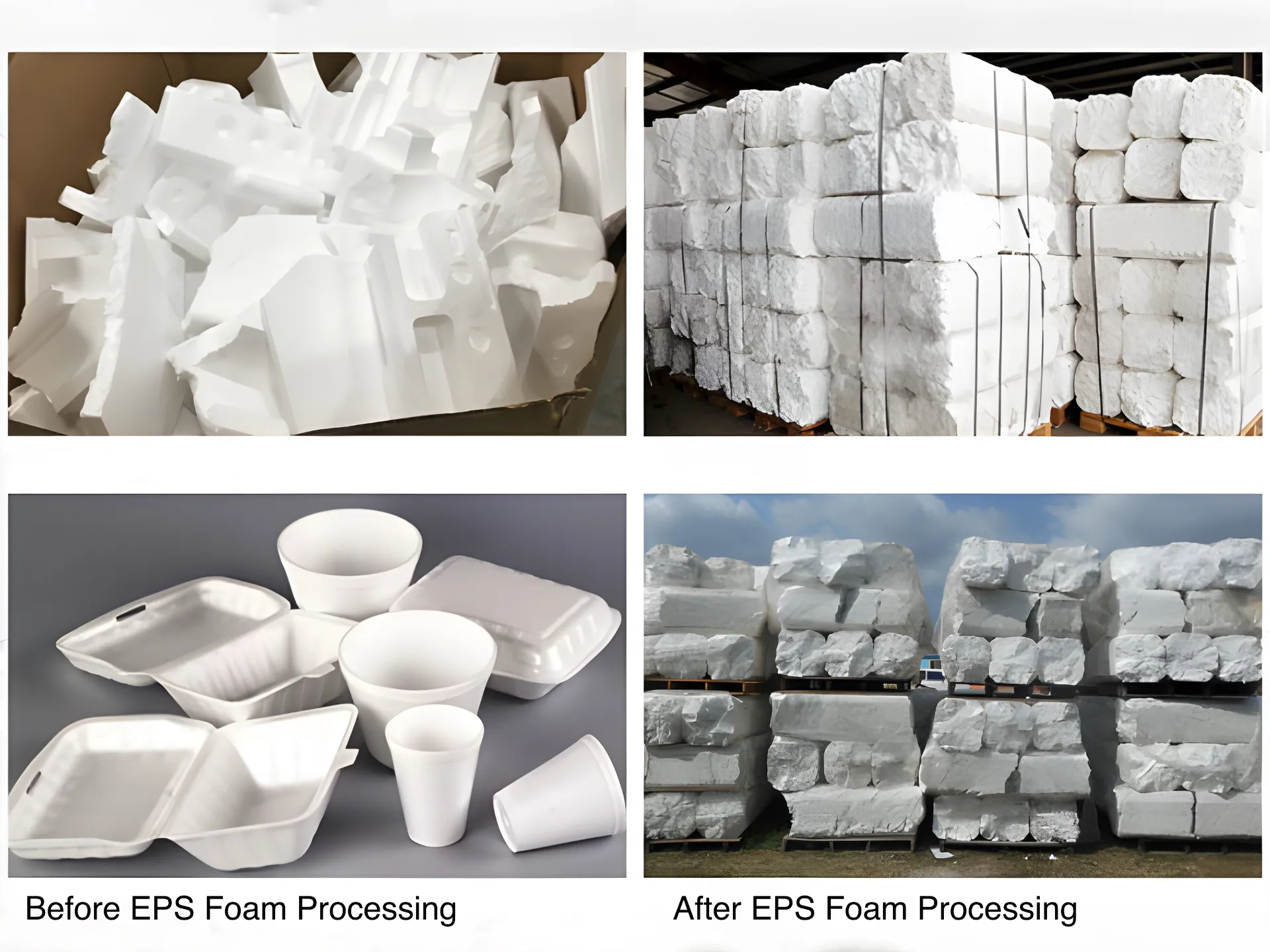

3. Formation of Dense Blocks

- The compressed foam is extruded into dense, uniform blocks or logs.

- These blocks are easier to handle, store, and transport, making them suitable for recycling or disposal.

4. Discharge and Collection

5. Advantages

Specification

| Model | GL-HM100 | GL-HM200 | GL-HM400 |

|---|---|---|---|

| Screw Diameter | Φ100mm | Φ180–120mm | Φ180–120mm |

| Screw Length | 1050mm | 2500mm | 2500mm |

| Screw Speed | 150 r/min | 110 r/min | 110 r/min |

| Output | 40–50 Kg/h | 80–120 Kg/h | 180–200 Kg/h |

| Screen Mesh Size | 40mm | 50mm | 50mm |

| Extrusion Pressure Interval | 300 min | 386 min | 366 min |

| Motor Power | 5.5 KW | 15 KW | 22 KW |

| Heating Power | 4 KW | 10 KW | 14 KW |

| Crushing Machine Power | 1.5 KW | 2.2 + 2.2 KW | 2.2 + 2.2 + 2.2 + 2.2 KW |

| Number of Crushers | 9 sets | 9 + 10 sets | 9 + 10 + 9 + 10 sets |

| Crusher Speed | 110 r/m | 110 mm | 110 mm |

| Dimensions | 1410×1085×1600 mm | 2030×1400×2050 mm | 3400×1880×2550 mm |

| Weight | 1000 Kg | 1800 Kg | 2500 Kg |

Warranty & Installation

Each recycling machine includes a 1-year limited warranty. We provide installation services, with our engineers visiting your site to assist with the setup process. Arrangements for regular maintenance crews and operational consultants can also be made.

Inquire Now

To get the latest prices and lead times, send us a message using the form below.