The recycling industry has seen tremendous growth in recent years, driven by increasing demand for sustainable practices and materials. One critical component of this industry is the PET (Polyethylene Terephthalate) bottle flake washing line—a sophisticated system designed to clean and process used PET bottles into high-quality flakes for reuse. Whether you're a recycling startup or an established business looking to upgrade your equipment, understanding the factors that influence the price of a PET bottle flake washing line is essential for making informed purchasing decisions. In this article, we’ll explore the key elements that affect the cost of these systems, offering practical insights to help you budget effectively and optimize your investment.

What Is a PET Bottle Flake Washing Line?

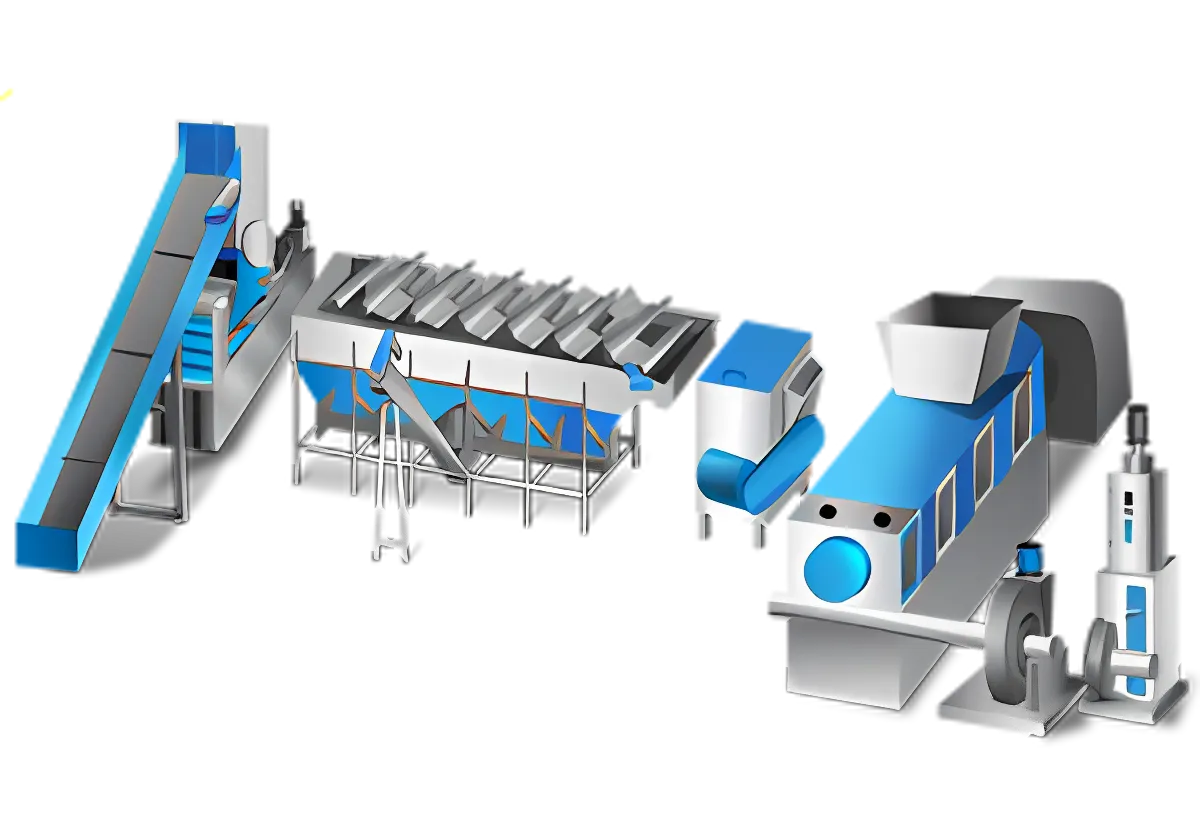

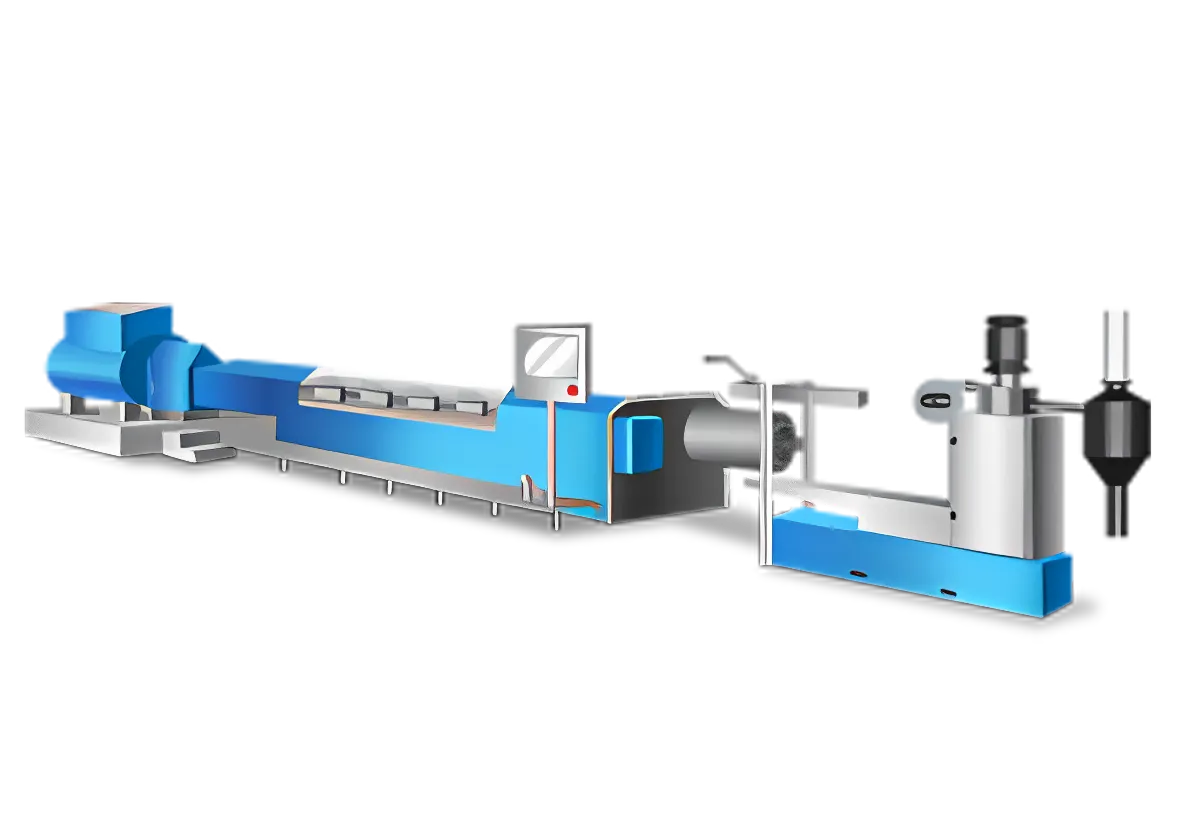

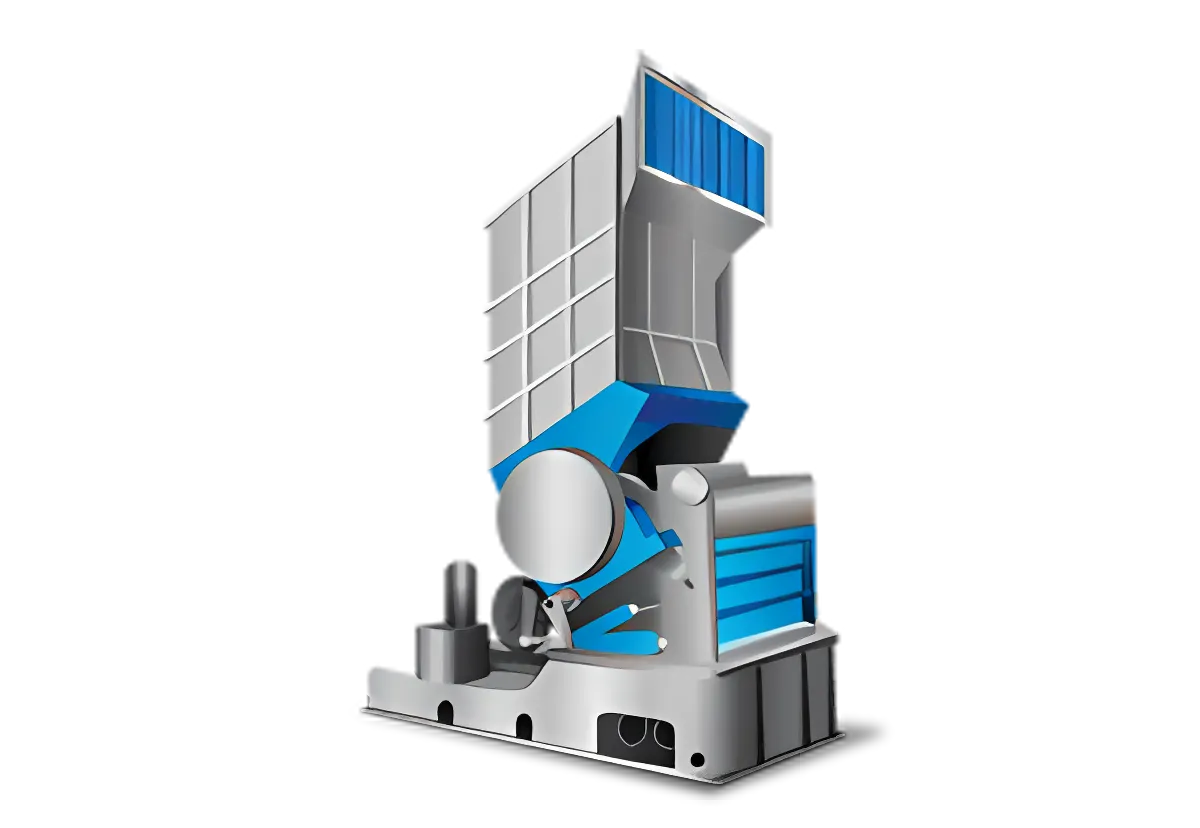

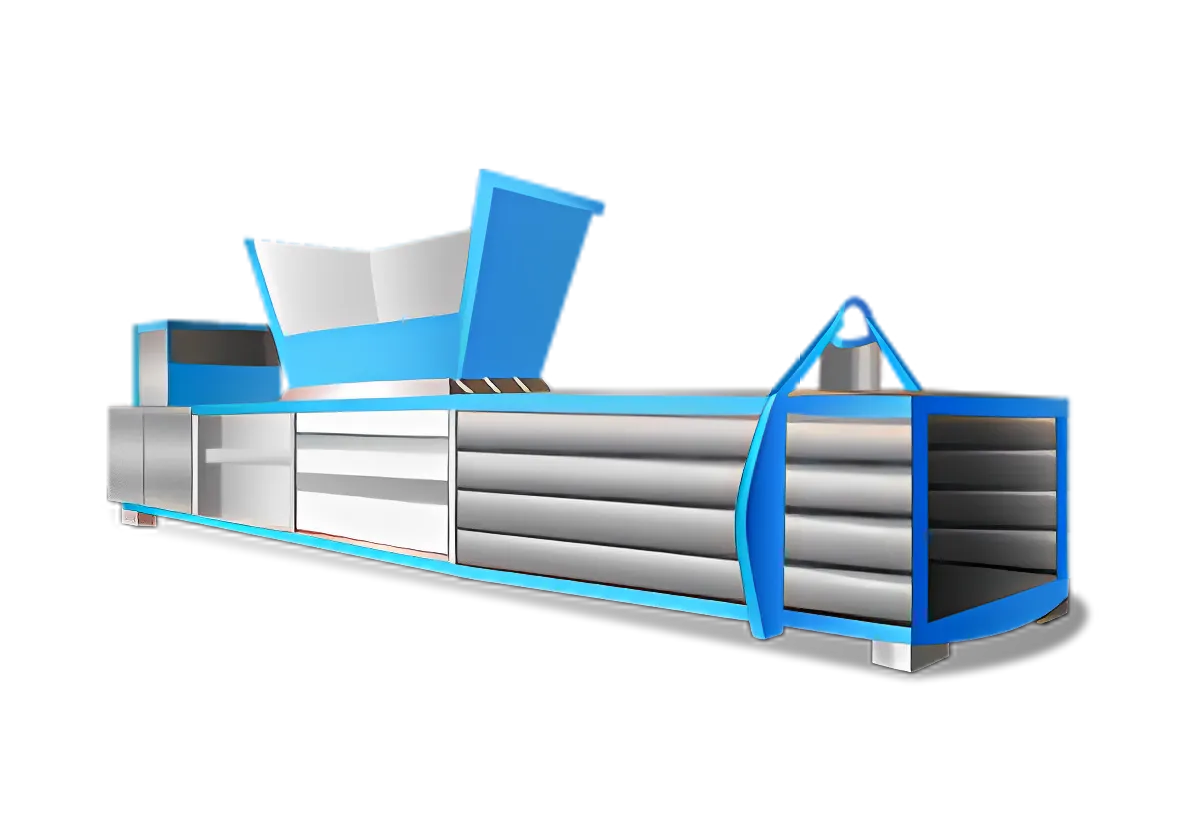

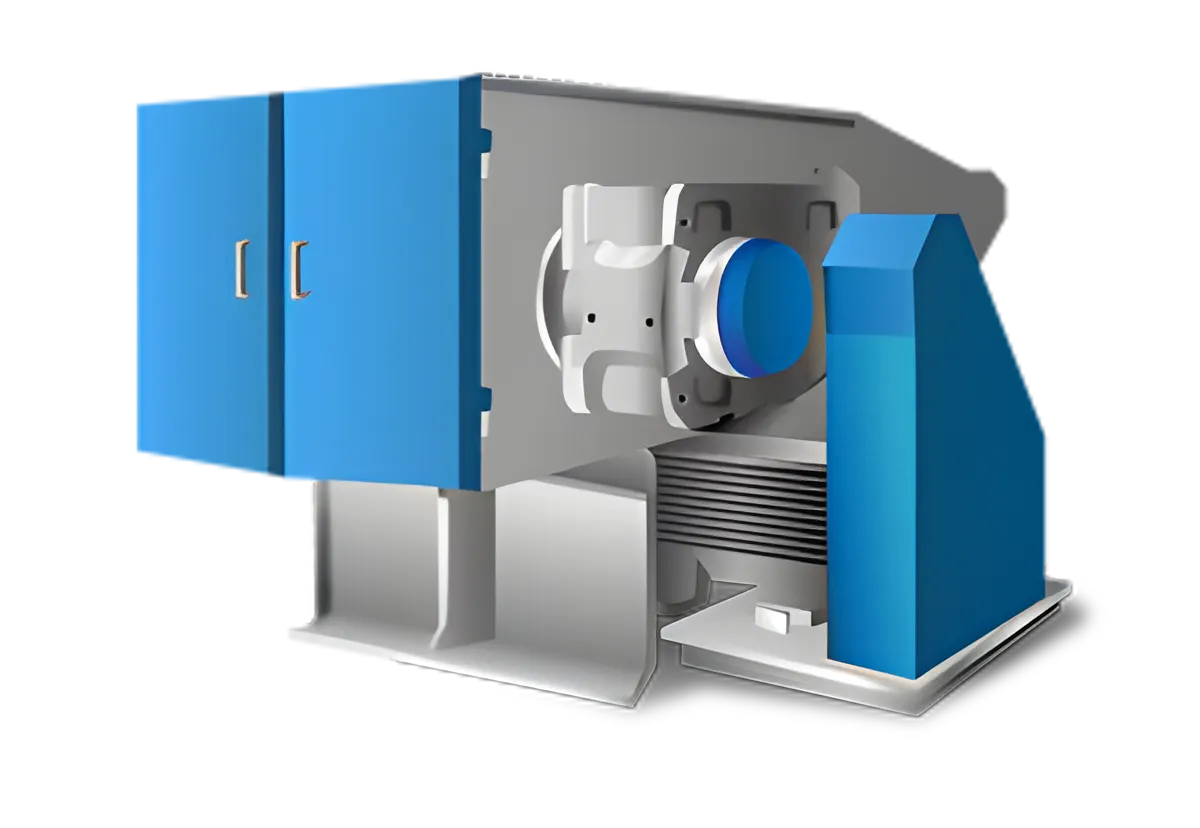

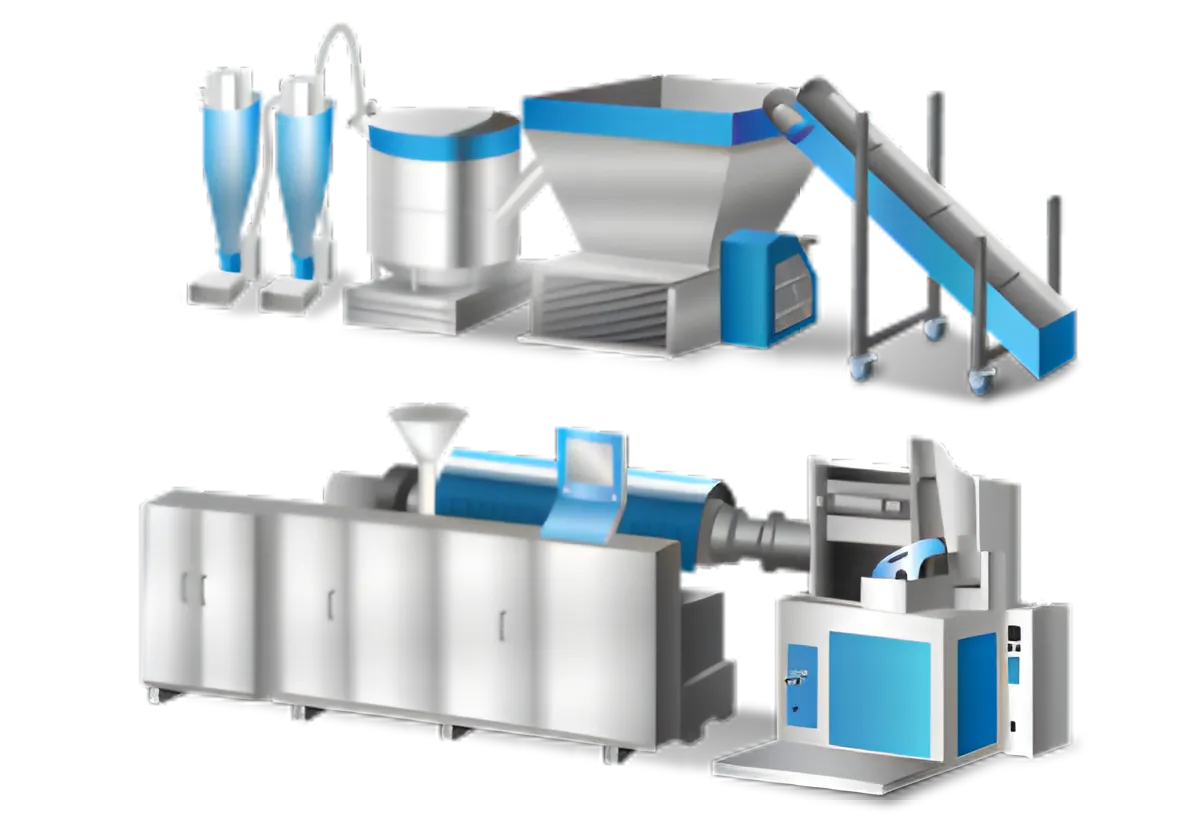

Before diving into the pricing factors, let’s clarify what a PET bottle flake washing line entails. This machinery is used to recycle post-consumer PET bottles (like water and soda bottles) by transforming them into clean, reusable flakes. The process typically includes sorting, crushing, washing, rinsing, drying, and sometimes pelletizing. The resulting PET flakes can be used to manufacture new bottles, textiles, or other plastic products. The price of this equipment can vary widely, ranging from tens of thousands to hundreds of thousands of dollars, depending on several variables. Let’s break them down.

Key Factors Influencing the Price

1. Production Capacity

The capacity of a PET bottle flake washing line—measured in kilograms or tons per hour—is one of the most significant cost drivers. A small-scale line with a capacity of 500 kg/hr will naturally cost less than a high-capacity system processing 3,000 kg/hr or more. Higher capacity lines require larger machines, more robust motors, and additional components to handle the increased throughput, all of which contribute to a higher price tag.

- Practical Insight: If you’re just entering the recycling market, start with a smaller capacity line (e.g., 500–1,000 kg/hr) to minimize upfront costs. As demand grows, you can scale up to larger systems.

- Gamme de prix: Small-scale lines might start at $50,000, while industrial-scale systems can exceed $300,000.

2. Level of Automation

Automation is a game-changer in modern recycling equipment. Fully automated washing lines, equipped with PLC (Programmable Logic Controller) systems and touch-screen interfaces, reduce labor costs and improve efficiency but come at a premium. Semi-automated or manual systems, while more affordable, require more human intervention, which can increase operational costs over time.

- Practical Insight: Consider your labor budget and production goals. For regions with high labor costs, investing in automation may pay off in the long run despite the higher initial price.

- Cost Impact: Fully automated systems can add $20,000–$100,000 to the base price compared to manual alternatives.

3. Material Quality and Durability

The materials used in constructing the washing line significantly affect its price and lifespan. High-quality systems often feature stainless steel (e.g., SUS304) for parts that contact water and plastic, ensuring corrosion resistance and durability. Cheaper models might use lower-grade materials, reducing upfront costs but potentially leading to higher maintenance expenses.

- Practical Insight: Opt for stainless steel components if you plan to run the line continuously or process heavily contaminated bottles. The initial investment will save you from frequent repairs.

- Cost Impact: Stainless steel construction can increase costs by 10–20% over basic steel or mixed-material options.

4. Washing Process Complexity

PET washing lines come in two main types: cold washing and hot washing. Cold washing uses room-temperature water and is more energy-efficient, making it cheaper to purchase and operate. Hot washing, which uses heated water to remove stubborn contaminants like grease or labels, requires additional heating systems and insulation, driving up the price.

- Practical Insight: Choose based on your input material. If your PET bottles are relatively clean, a cold washing line may suffice. For heavily soiled bottles or food-grade flake production, hot washing is worth the extra cost.

- Cost Impact: Hot washing systems can cost 15–30% more than cold washing lines due to added heating and energy requirements.

5. Customization and Additional Features

Every recycling operation has unique needs, and manufacturers often offer customizable options. Features like advanced sorting systems (e.g., color or material sorters), friction washers, or specialized drying units can enhance flake quality but increase the price. Similarly, turnkey solutions that include installation and training will cost more than basic equipment packages.

- Practical Insight: Prioritize features that align with your end-product goals. For example, if you’re targeting food-grade PET flakes, invest in high-quality sorting and washing add-ons.

- Cost Impact: Customization can add $10,000–$50,000 or more, depending on the complexity.

6. Manufacturer Reputation and Origin

The brand and country of origin play a big role in pricing. Established manufacturers with a proven track record (e.g., from Europe or North America) often charge more due to superior engineering and after-sales support. Conversely, manufacturers from regions like China may offer competitive pricing, though quality and support can vary.

- Practical Insight: Research supplier reviews and request references. A slightly higher price from a reputable brand might be justified by reliability and service, especially for long-term operations.

- Cost Impact: European or U.S.-made lines might cost 20–50% more than similar systems from emerging markets.

7. Energy and Water Efficiency

Sustainability is a growing concern, and energy-efficient machines can lower operating costs. However, these systems often require advanced technology—like heat recovery systems or optimized water recycling—which increases the purchase price. Lines designed to minimize water usage also tend to cost more due to additional filtration and treatment components.

- Practical Insight: Calculate your local energy and water costs. In areas with high utility rates, an efficient system could offset the higher upfront cost within a few years.

- Cost Impact: Energy-efficient designs can raise prices by 10–25%.

8. After-Sales Support and Warranty

A comprehensive warranty and reliable after-sales service (e.g., spare parts availability, technical support) can add to the cost but provide peace of mind. Budget models might lack robust support, leaving you vulnerable to downtime and repair expenses.

- Practical Insight: Factor in the cost of downtime. A slightly pricier system with a strong warranty might be cheaper than frequent repairs on a budget model.

- Cost Impact: Extended warranties and support packages can add $5,000–$20,000 to the total.

Hidden Costs to Consider

Beyond the sticker price, several hidden factors can affect your total investment:

- Shipping and Installation: Importing equipment from overseas can incur significant freight and customs fees, while installation might require specialized technicians.

- Coûts opérationnels: Energy, water, and labor expenses vary by region and system efficiency.

- Entretien: Regular servicing and replacement parts should be budgeted annually.

Practical Insight: Request a detailed quote that includes shipping, installation, and a year’s worth of operational cost estimates to avoid surprises.

How to Optimize Your Investment

To get the best value for your money, follow these steps:

- Assess Your Needs: Determine your production volume, input material quality, and target flake purity to avoid over- or under-spending.

- Compare Quotes: Source proposals from multiple suppliers and evaluate them based on features, not just price.

- Negotiate: Many manufacturers offer discounts or flexible payment terms, especially for bulk or repeat orders.

- Plan for Scalability: Choose a system that can be upgraded rather than replaced as your business grows.

Conclusion

The price of a PET bottle flake washing line is influenced by a mix of technical, operational, and market factors. From production capacity and automation to material quality and manufacturer reputation, each element plays a role in determining the final cost. By understanding these variables and aligning them with your business goals, you can invest wisely in a system that delivers both quality flakes and long-term profitability. Whether you’re aiming for a budget-friendly setup or a high-end, food-grade operation, thorough research and planning are your keys to success in the dynamic world of PET recycling.

Ready to take the next step? Start by defining your recycling goals and reaching out to suppliers for tailored quotes—your sustainable future awaits!