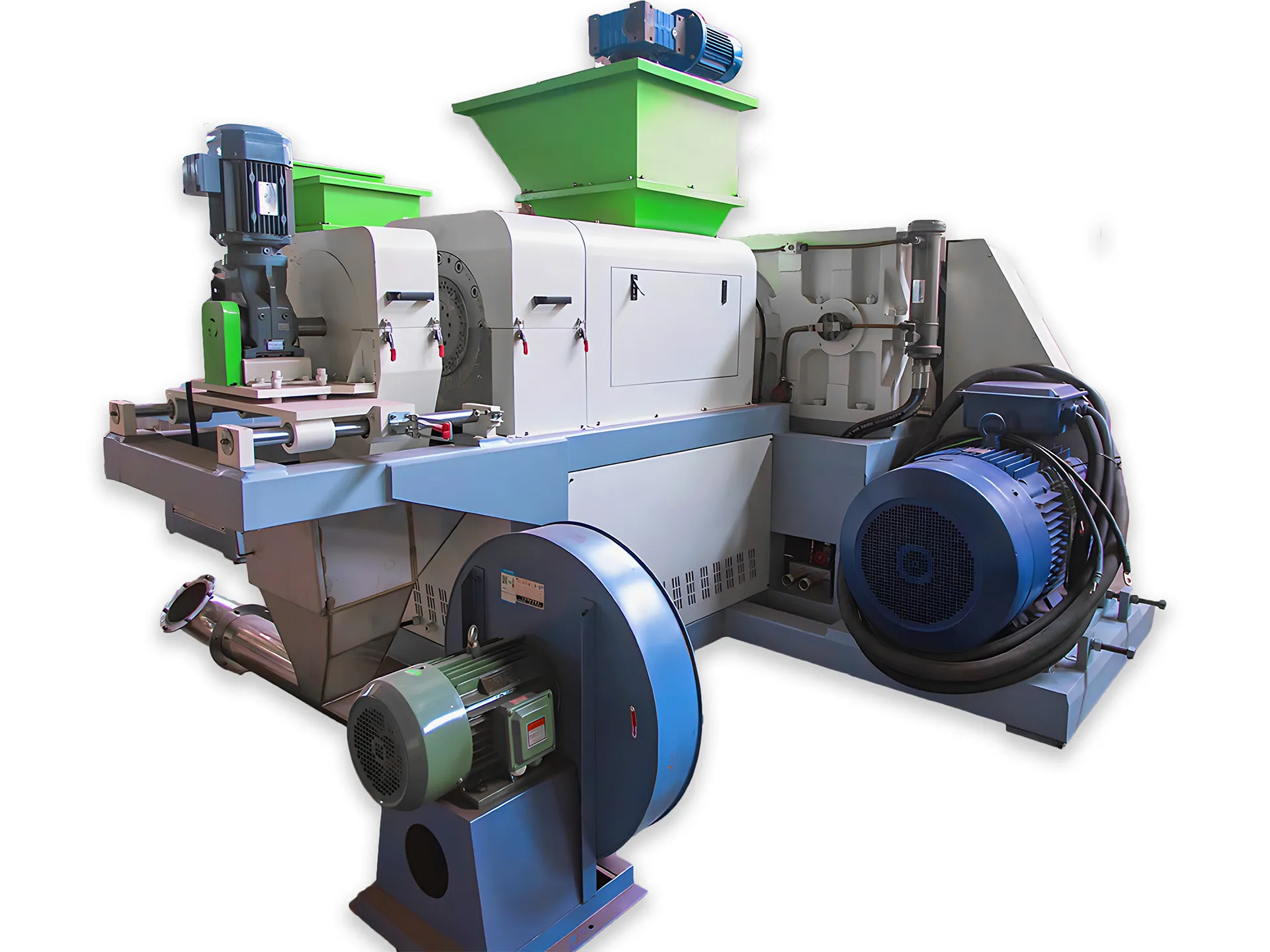

The Plastic Film Squeezer & Densifier System is a cutting-edge piece of equipment designed to transform voluminous, low-density plastic film waste into a denser, semi-dry, and easily manageable form. This innovative system significantly enhances the efficiency of downstream recycling processes, reduces transportation costs, and ultimately contributes to a more sustainable and profitable operation.

Unlock the Potential of Your Plastic Film Waste:

Our Squeezer & Densifier System offers a comprehensive solution with a focus on Fonctionnalité, Avantages, et Quality:

Key Functions:

- Efficient Water Removal: Effectively squeezes out moisture from washed plastic film, significantly reducing water content (from 40% down to only 2-5%).

- Volume Reduction: Dramatically decreases the bulk volume of the film, making it easier and cheaper to transport and store.

- Préparation du matériel : Prepares the film for subsequent processing stages like pelletizing or extrusion by creating a more uniform and dense material.

- Contaminant Removal (Optional): Some configurations can assist in removing residual fine contaminants through the squeezing action.

Unmatched Advantages:

- Increased Recycling Efficiency: Denser material feeds more consistently and efficiently into extruders and pelletizers, leading to higher throughput and better quality recycled products.

- Significant Cost Savings: Reduced water content translates to lower energy consumption during drying processes. Decreased volume minimizes transportation and storage expenses.

- Enhanced Material Quality: The densified material is more uniform and less prone to bridging or feeding issues in downstream equipment.

- Environmentally Friendly: By efficiently processing plastic film waste, you contribute to a circular economy and reduce the amount of plastic ending up in landfills.

- Utilisation conviviale : Designed for ease of use and maintenance, minimizing downtime and maximizing productivity.

- Solutions personnalisables : Available in various sizes and configurations to meet specific processing needs and capacity requirements.

Superior Qualities:

- Construction robuste : Built with high-quality materials and components to ensure durability and long-term reliable performance, even in demanding industrial environments.

- Advanced Engineering: Incorporates innovative design principles for optimal squeezing and densifying action, maximizing efficiency and minimizing energy consumption.

- Performances fiables : Engineered for consistent and dependable operation, minimizing maintenance requirements and ensuring continuous production.

- Caractéristiques de sécurité : Equipped with comprehensive safety mechanisms to protect operators and ensure a safe working environment.

- Technical Support: Backed by our experienced technical team, providing comprehensive support for installation, operation, and maintenance.

Spécification:

| Modèle | Diamètre de la vis | Screw Barrel Material & Treatment | Puissance du moteur | Puissance de chauffage | Capacité |

|---|---|---|---|---|---|

| ERMSD250 | 250 mm | 38CrMoAlA Nitride | 90 kW | 15 kW | 200-300kg/h |

| ERMSD300 | 300 mm | 38CrMoAlA Nitride | 110-132kw | 22 kW | 300-400kg/h |

| ERMSD320 | 320mm | 38CrMoAlA Nitride | 160-185kw | 30 kW | 500-600kg/h |

| ERMSD350 | 350 mm | 38CrMoAlA Nitride | 200-220kw | 36kw | 700-800kg/h |

Ready to take your plastic film recycling to the next level?

Contact us today to learn more about how our Plastic Film Squeezer & Densifier System can revolutionize your operations and contribute to a more sustainable future.