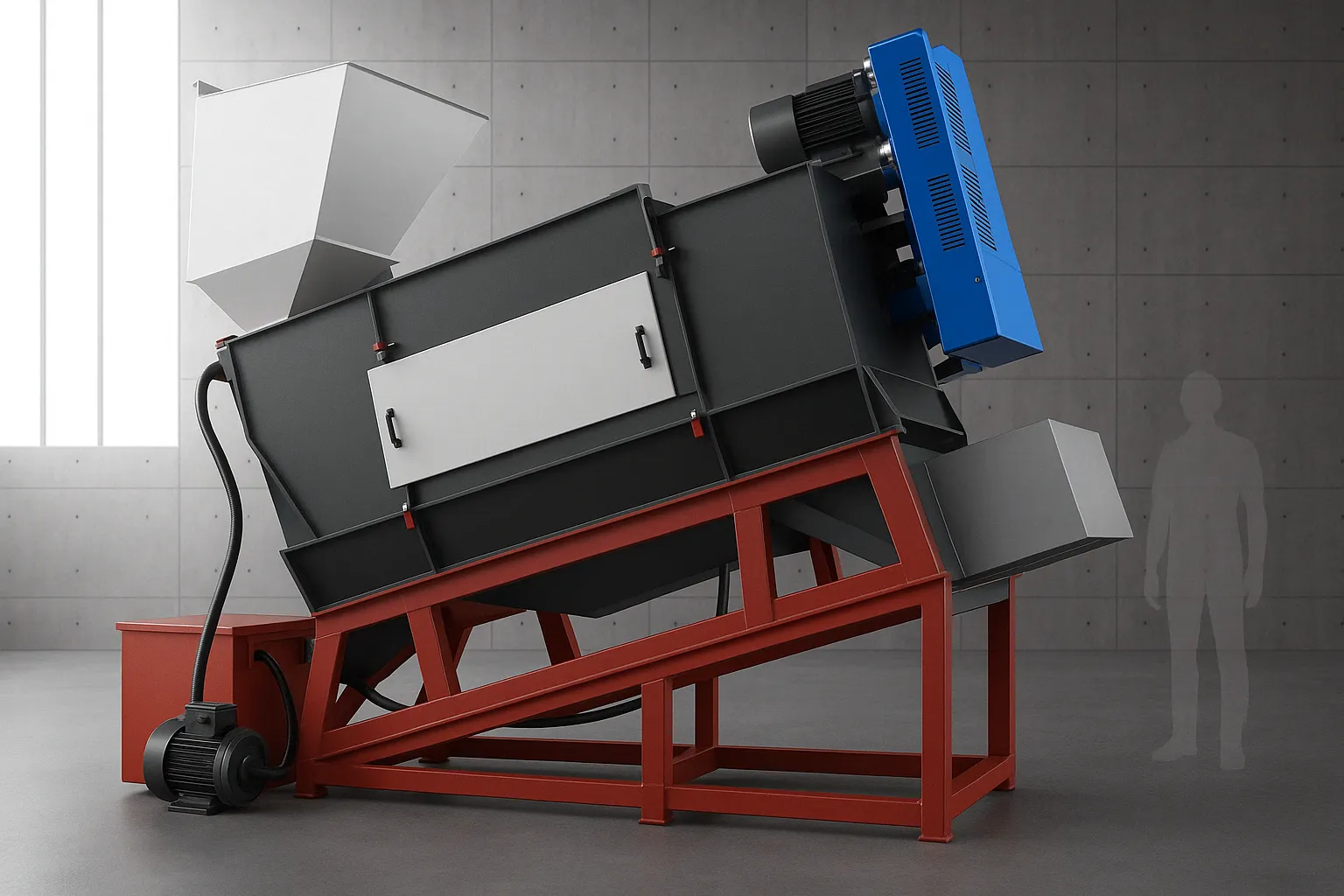

Décapant d'étiquettes de bouteilles en plastique humides

Revolutionary Solution for Enhancing Recycled Plastic Quality – Removes Over 95% of Labels While Efficiently Cleaning PET Bottles

Haute efficacité

Removes over 95% of labels, significantly reducing contamination in PET flakes

Dual Functionality

Combines label removal and bottle cleaning, streamlining the processing workflow

Durable Components

Premium alloy knives that can be removed, sharpened, and replaced for longevity

Rentable

Enhances recycling efficiency, reducing labor and processing costs

Comment ça marche

Our Wet Plastic Bottle Label Remover employs advanced mechanical and hydraulic technology to efficiently remove labels from plastic bottles while performing initial cleaning, establishing a foundation for subsequent recycling processes.

Bottle Input

Plastic bottles enter the machine through the feeding system

Blade Cutting

Special alloy knives cut and tear labels from bottles

Water Spray

Water jets wash cut labels into a collection chute

Bottle Separation

Cleaned bottles are ready for the next recycling stage

Spécifications techniques

| Paramètre | Spécification |

|---|---|

| Capacité de traitement | 500-2000 kg/h (depending on model) |

| Label Removal Efficiency | 80%-98% (typically over 95%) |

| Blade Material | Imported alloy, copper-welded |

| Rotor Speed | Medium rotation speed, adjustable angles |

| Cleaning System | High-pressure water jet technology |

| Caractéristiques de maintenance | Removable, re-sharpenable, and replaceable blades |

Why Choose Our Wet Plastic Bottle Label Remover

Enhanced Recycled Material Quality

By removing labels prior to further processing, our equipment reduces contamination in PET flakes, producing higher quality recycled materials. This is crucial for applications requiring pure PET, such as new bottle production or fiber manufacturing.

Increased Production Efficiency

The integration of label removal and cleaning into a single step streamlines the recycling process, potentially reducing labor costs and increasing throughput for your operation.

Reduced Operational Costs

By improving overall efficiency, our equipment can lower operational costs, enabling recycling facilities to optimize their processes and achieve better returns on investment.

Environmental Contribution

By enhancing recycling efficiency and the quality of recycled materials, our equipment makes a significant contribution to the circular economy for plastics and environmental protection.

Elevate Your Plastic Recycling Operation

Discover how the Wet Plastic Bottle Label Remover can improve your production efficiency and recycled material quality

Contact Us for a QuoteQuestions fréquemment posées

What is the maintenance cycle for the equipment?

Our Wet Plastic Bottle Label Remover is designed for low maintenance requirements. It is generally recommended to inspect the blades every 1-2 months and sharpen or replace them according to usage. Other components have longer maintenance cycles, typically requiring a comprehensive inspection every six months.

Can the equipment handle various types of labels?

Yes, our equipment can process most common plastic bottle labels, including paper labels, plastic labels, and shrink sleeve labels. For particularly difficult labels, equipment parameters may need to be adjusted for optimal results.

How can I integrate the equipment into my existing recycling line?

Our Wet Plastic Bottle Label Remover is designed to be modular and can be easily integrated into existing PET bottle recycling lines. It is typically installed before crushing and deep cleaning processes, and our technical team provides complete installation and integration support.

What are the operating costs for the equipment?

Operating costs vary by equipment model and scale, but overall, our equipment offers better cost-effectiveness compared to traditional methods. By improving recycled material quality and simplifying subsequent processing steps, the long-term cost savings typically far exceed the initial investment and operating costs.