Concentric Eddy Current Separators are expertly engineered devices that excel in the seamless extraction of tiny non-ferrous particles from high-volume materials across various recycling applications. They demonstrate remarkable proficiency in classifying small fragments of aluminum waste.

- Capable of sorting materials as small as 2mm.

- Specifically designed to identify micro non-ferrous metallic impurities.

- Ideally suited for purification processes in PET plastic flake streams.

- Applicable for glass scrap recycling and wet sorting of Incinerator Bottom Ash (IBA) processing.

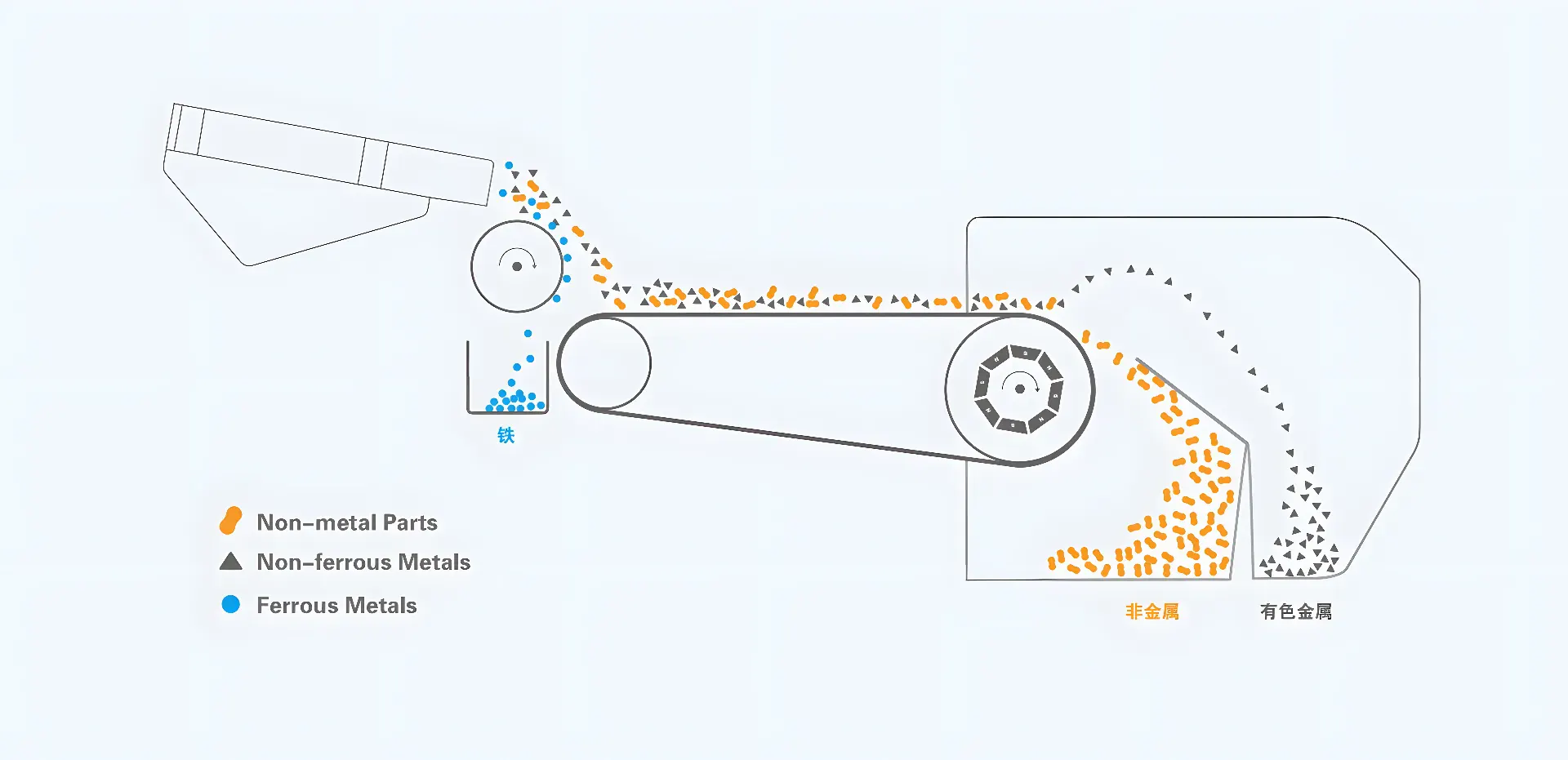

The technical principle of the concentric eddy current separator is akin to that of the eccentric eddy current separator; however, their purposes differ. The concentric rotor features an alternating pole Rare Earth magnet system that completely occupies the available space within the separation rotor drum. This magnet system rotates at high speeds, maintaining a distance of just a few millimeters from the outer shell surface, thereby generating extremely high ‘eddy currents’ on the surface and resulting in substantial repulsive forces.

Key Features

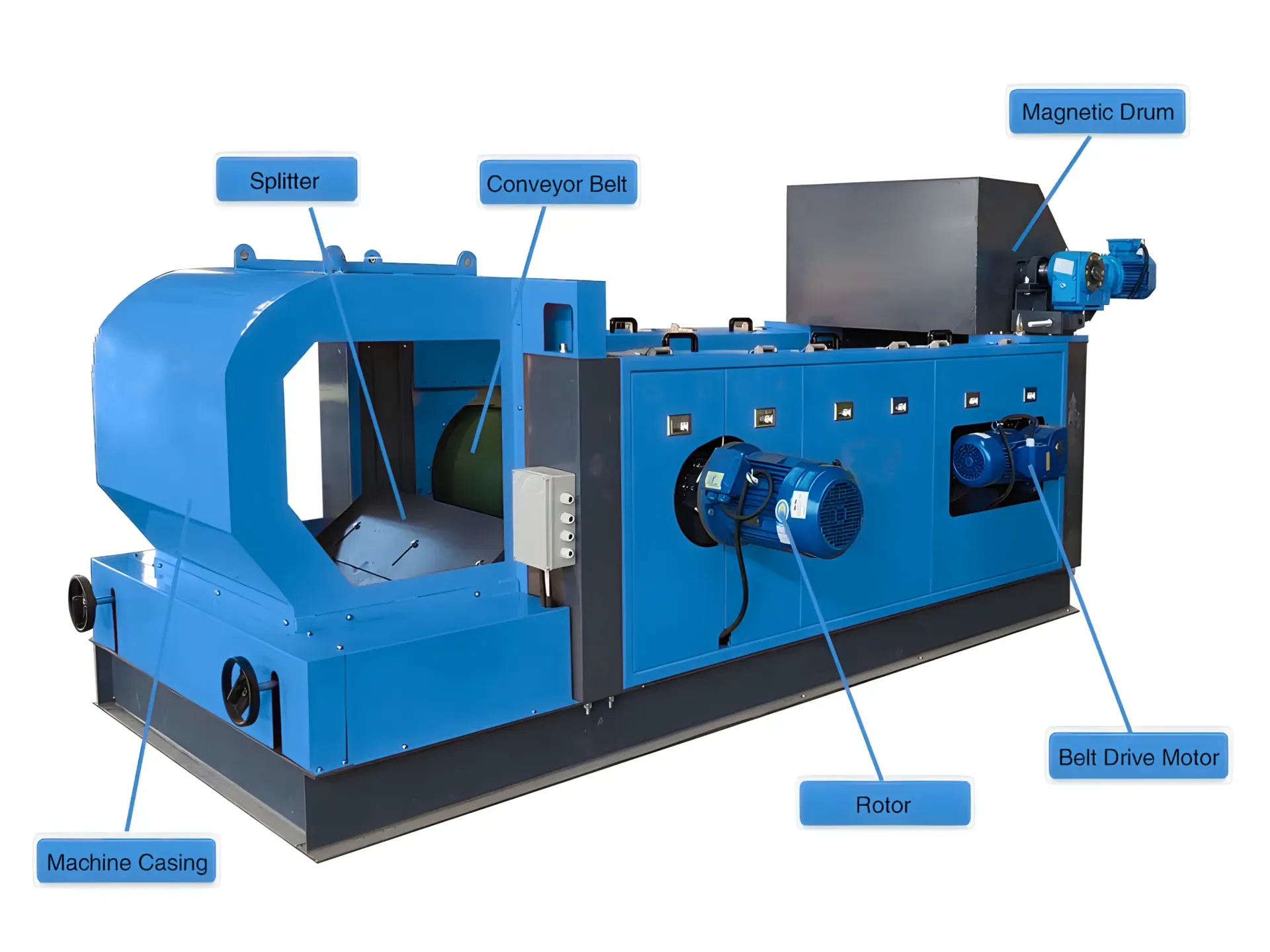

Magnetic Separation

The optional 3,000 Gauss drum magnet and 15,000 Gauss high-intensity roller are designed for the separation of small amounts of residual ferrous metals and magnetic stainless steel, protecting the concentric pole eddy current separator and other recycling equipment.

Feeding Systems

Maximize separation efficiency with uniform single-layer feeding facilitated by an optional vibratory feeder, complemented by custom-built feeding and splitter systems for high extraction and optimized recovery of non-ferrous materials.

Drive Motors

Standardly equipped with ABB® drive motors, with optional SEW® motors, all electronic components are UL and CSA certified, featuring a variable speed control panel for flexible operations using VFDs.

Drum Motor

The compact and maintenance-free integrated drum motor powers the conveyor belt with an IP66 protection rating, ensuring durability and ease of use for operators.

High-Frequency Rotor

The high-frequency rotor utilizes high-performance rare earth magnet NdFeB, featuring a robust and durable double-layer tubular structure, with a rotor speed of 3000-4000 RPM and a belt surface strength of 4500Gs.

Conveyor Belts

A diverse range of short conveyor belts is available, including thin, corrugated, PU, PVC, and rubber varieties, offered in various widths and models. The cantilever frame design allows for belt replacement in just 10 minutes.

Design & Customization

Our compact integrated design, along with specialized surface treatments tailored to various industries, significantly extends the equipment’s lifespan. Additionally, we offer customized colors based on customer preferences.

Adjustable Separation Plate

The separation plate is manually adjustable in angle, height, and distance, working in conjunction with rotor speed and position to achieve flawless 100% non-ferrous metal separation. Typically crafted from manganese steel or Trespa, these components ensure optimal performance.

Typical Applications

IBA

Recovering non-ferrous metals from waste incineration bottom ash.

RDF & SRF

Advanced sorting of commercial waste, floating metals to maximize energy recovery for value-derived full production.

ZORBA

With competitive prices and the best sorting efficiency, we are ready to enhance the quality and purity of your ZORBA.

Plastic

Enhancing plastic purity by separating non-ferrous metals with eddy current separators and expelling metal impurities.

Wood & Compost

Separation of non-ferrous metals from wood industry, paper industry, and compost.

WEEE

Efficiently extracting non-ferrous metals from waste electrical and electronic equipment.

Foundry Residues

Purifying and recycling casting residues in metal casting, machinery, and foundry industries.

Metal Grade Sorting

Sorting various grades of metals, including polymetallic materials like aluminum, copper, lead, and zinc in different sizes of continuous scrap for recycling.

Windows

Recycle aluminum components from UPVC Window Frames (Screened).

Specifications

| Model | Dimensions (L*W*H) mm | Rotor Speed r/min | Effective Belt Width mm | Belt Speed m/s | Drive Power kW |

|---|---|---|---|---|---|

| 40A | 2080*1357*1100 | 0-3000 | 330 | 0-2 | 0.75 |

| 65A | 3300*1500*1200 | 0-4000 | 520 | 0-2 | 1.5 |

| 80A | 3300*1700*1200 | 0-4000 | 670 | 0-2 | 2.2 |

| 100A | 3300*1900*1200 | 0-4000 | 840 | 0-2 | 2.2 |

| 120A | 3300*2000*1200 | 0-4000 | 1040 | 0-2 | 2.2 |

| 140A | 3300*2130*1587 | 0-4000 | 1200 | 0-2 | 2.2 |

| 160A | 3300*2300*1200 | 0-4000 | 1440 | 0-2 | 2.2 |

| 180A | 3300*2700*1200 | 0-4000 | 1500 | 0-2 | 2.2 |