Our Horizontal Fully Automatic Hydraulic Baler represents the pinnacle of modern waste compression technology, designed to handle various materials like cardboard, paper, plastic film, and straw. This innovative baler is widely adopted in industries such as packaging, corrugation, breweries, recycling centers, and printing plants, providing exceptional efficiency and dependability.

Key Features and Advantages

- Durable, Heavy-Duty Construction: The robust body of the baler requires only a flat ground surface for installation, making it both versatile and easy to set up.

- Automatic Activation with Photoelectric Switch: The baler activates automatically once the charge box reaches capacity, streamlining the process and reducing manual intervention.

- Double-Cutting Design for Enhanced Efficiency: Featuring a unique double-cutting design, the cutters improve processing speed and extend the lifespan, ensuring sustained operational efficiency.

- Anti-Slide Mechanism for Consistent Bale Quality: An integrated anti-slide design ensures that the bales produced are uniform and compact, meeting industry standards.

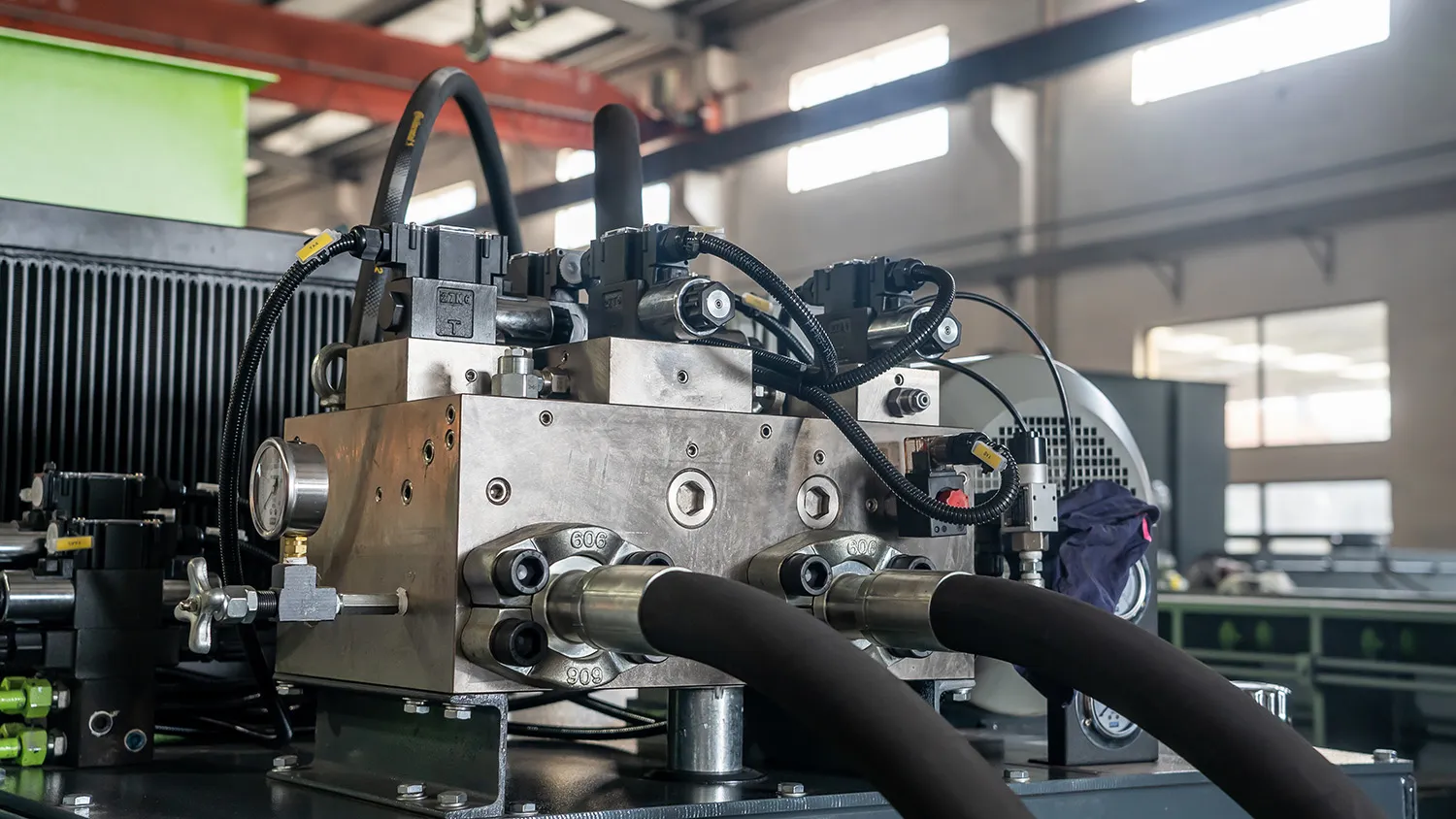

- Trunnion-Mounted Frame & Ball-End Joint: The main cylinder’s trunnion-mounted frame and ball-end joint reduce torque on the rod, thereby increasing the seal’s lifespan and overall machine durability.

- Automatic Tying System: The rapid tying mechanism enables fast binding of bales, reducing downtime and facilitating easy cleaning and maintenance.

- Differential Hydraulic System for Speed & Energy Efficiency: The differential technique in the hydraulic system shortens cycle time, enhances operational speed, and reduces energy consumption.

- Automatic Tensioning for “Brick-Like” Bales: This feature ensures that bales maintain a consistent, brick-like structure, especially for loose materials.

- Adjustable Bale Length & Quantity Accumulation: Operators can easily set bale length and accumulate bale quantities, making operation more convenient and user-friendly.

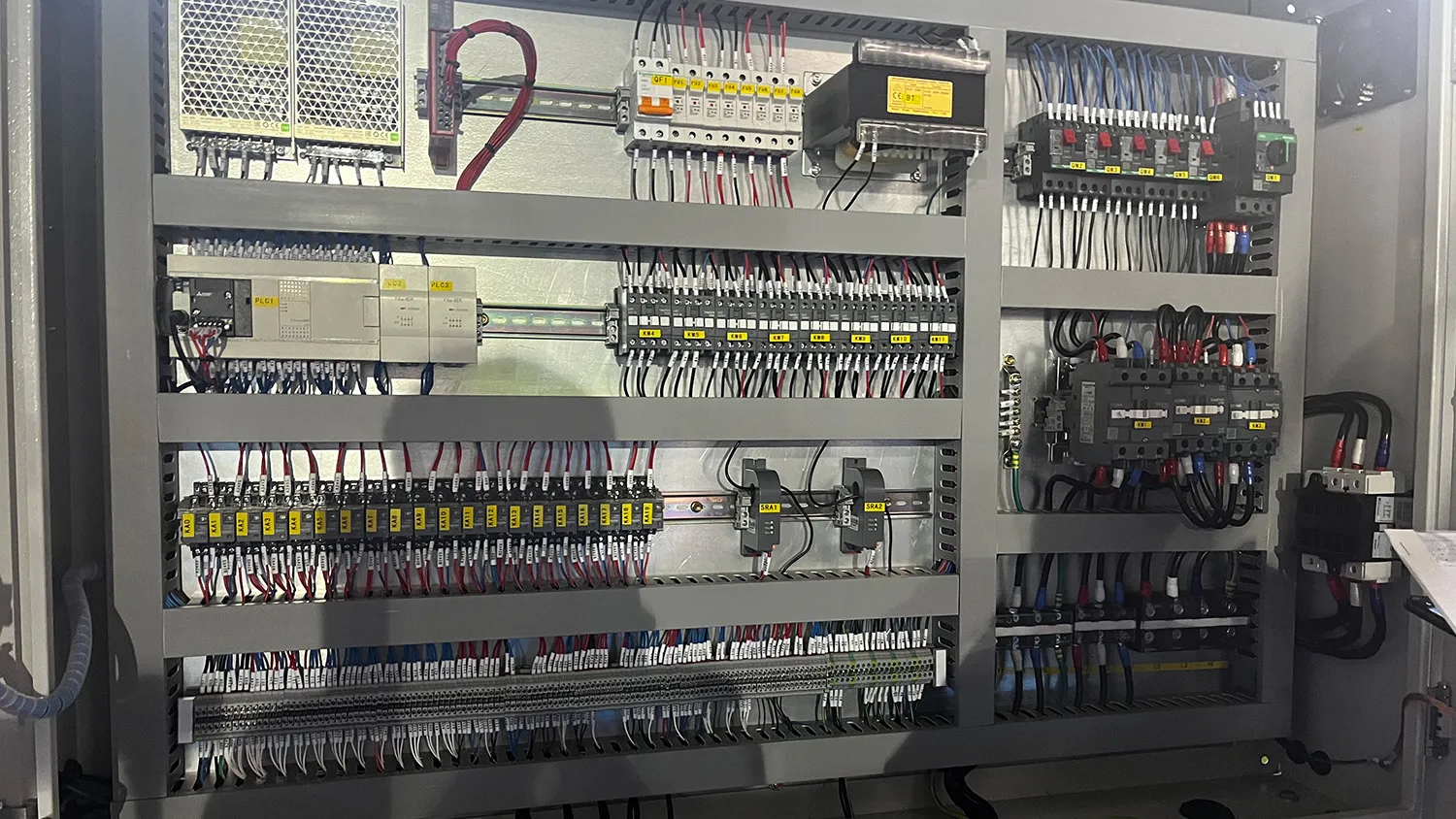

- Error Detection System: The built-in error detection system identifies malfunctions quickly, increasing inspection efficiency and reducing downtime.

- Standardized Electrical Layout: The international-standard electric circuit layout, combined with graphic instructions and detailed part markers, simplifies operation and maintenance.

- High-Precision Press Heads: The press heads are machined using a planomiller, ensuring accurate and smooth operation.

- Taiwanese Hydraulic System: The use of premium hydraulic systems from Taiwan guarantees stable and reliable machine performance.

Specifications

| Model | RTM-600W11075-30 | RTM-800W11075-50 |

|---|---|---|

| Pressure | 60tons | 80tons |

| Main Motor Power | 22kw | 37.5kw |

| Cooling System | air cooler / water cooler | air cooler / water cooler |

| Cycle Time (unload) | 24s | 16s |

| Oil Reservoir | 1000L | 1100L |

| Number of Belting | 4lines | 4lines |

| Wire Size | ?2.7-3.0 | ?2.7-3.0 |

| Feed Opening Size (L*W) | 1600*1050mm | 1600*1050mm |

| Chamber Size (L*W*H) | 2100*1100*750mm | 2100*1100*750mm |

| Bale Size (L*W*H, L is adjustable) | L*1100*750mm | L*1100*750mm |

| Bale Density (OCC) | 400-500kgs/m3 | 420-500kgs/m3 |

| Throughput (30-60kgs/m3) | 3-7tons/h | 4-8tons/h |

| Machine Weight | 13tons | 14tons |

| Machine Overall Dimension | 7950*3950*3500mm | 8100*3900*3500mm |

| Feeding Device | Conveyor | Conveyor |

| Conveyor | ||

| Feeding Width | 1600mm | 1600mm |

| Speed | 12m/min | 12m/min |

| Power | 4/5.5KW | 4/5.5KW |

| Weight | 5tons | 5tons |

| Overall Dimension | 9000*2100*4500mm | 9000*2100*4500mm |

FAQs

1. How much does a horizontal baler cost?

The cost varies based on specifications and features. Contact us for a tailored quote.

2. What is a stealth baler?

Stealth balers are designed for compact spaces and operate quietly, making them suitable for various settings.

3. What is an automatic baler?

An automatic baler compresses waste materials into bales without manual intervention, boosting productivity.

4. Difference between vertical and horizontal balers?

Vertical balers suit smaller waste volumes with manual tying, while horizontal balers manage larger volumes with automatic tying.

Inquiries

To get the latest prices and lead times, send us a message using the form below.