Integrating a centrifugal dryer into your plastic recycling workflow can significantly improve efficiency, reduce drying time, and lower energy costs. Centrifugal dryers are essential for removing moisture from plastic pellets, flakes, or regrind after washing. To maximize their benefits, you need a clear strategy for installation, operation, and maintenance. This guide explains how to seamlessly incorporate a centrifugal dryer into your recycling process.

1. Understand the Role of a Centrifugal Dryer in Recycling

Before integrating a centrifugal dryer, it’s important to understand its function. A centrifugal dryer uses high-speed spinning and airflow to remove water from plastic materials. Unlike thermal drying methods, it relies on mechanical force, making it energy-efficient and faster. This step is critical in recycling because excess moisture can affect the quality of the final product, such as plastic pellets or flakes.

By incorporating a centrifugal dryer, you can:

- Improve the quality of recycled plastic.

- Reduce drying time compared to traditional methods.

- Lower energy consumption, as it minimizes the need for heat-based drying.

2. Evaluate Your Current Workflow

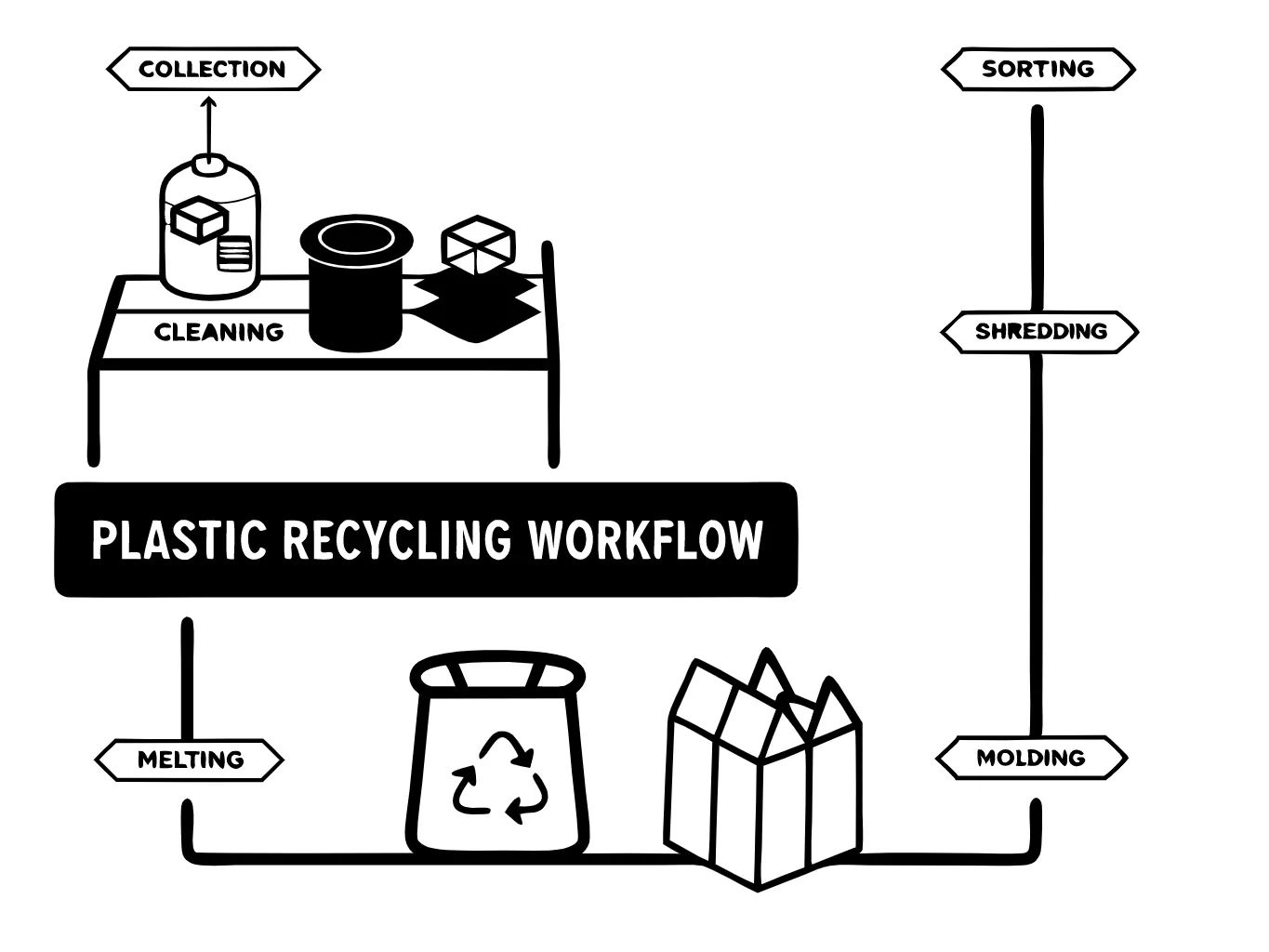

To integrate a centrifugal dryer effectively, assess your existing recycling process. Identify where the dryer fits best to optimize efficiency. Typically, the centrifugal dryer is placed after the washing and rinsing stages but before storage or extrusion.

Key Questions to Ask:

- What materials are you processing? Centrifugal dryers work best for rigid plastics like PET, HDPE, and PP. Ensure the dryer is compatible with your material type.

- What is your current moisture removal method? If you’re using thermal drying, switching to a centrifugal dryer can reduce energy costs.

- What is your processing capacity? Choose a dryer that matches your throughput to avoid bottlenecks.

3. Choose the Right Centrifugal Dryer

Selecting the right dryer is crucial for seamless integration. Consider the following factors:

Capacity

Match the dryer’s capacity to your recycling line’s output. For example, if your washing line processes 1,000 kg/hour, the dryer should handle the same volume without delays.

Material Compatibility

Ensure the dryer can handle the size and type of plastic you process. Some dryers are better suited for small flakes, while others handle larger pellets or regrind.

Energy Efficiency

Look for models with energy-saving features, such as variable speed motors or optimized airflow systems. These features reduce operating costs over time.

Maintenance Requirements

Choose a dryer with easy-to-clean components and minimal downtime for maintenance. This ensures consistent performance and reduces disruptions.

4. Plan the Installation Process

Proper installation is key to integrating the centrifugal dryer into your workflow. Work with your equipment supplier to ensure the dryer is installed correctly and aligned with your existing machinery.

Steps for Installation:

- Position the Dryer: Place the dryer immediately after the washing system. Use conveyors or piping to transfer materials directly into the dryer.

- Connect Utilities: Ensure the dryer has access to power and, if required, compressed air. Verify that the electrical setup meets the manufacturer’s specifications.

- Test the System: Run a trial to check for proper alignment, material flow, and moisture removal efficiency. Adjust settings as needed.

5. Optimize Workflow Integration

Once installed, optimize the dryer’s operation to maximize efficiency. This involves fine-tuning the process and ensuring smooth coordination between the dryer and other equipment.

Tips for Optimization:

- Adjust Speed and Settings: Set the dryer’s speed and airflow to match the material type and moisture level. For example, lighter flakes may require lower speeds to prevent damage.

- Monitor Moisture Levels: Use moisture sensors to ensure the output meets your quality standards. Adjust the dryer’s operation if moisture levels are too high.

- Minimize Downtime: Schedule regular maintenance to keep the dryer running efficiently. Clean the drum and inspect moving parts to prevent wear and tear.

6. Train Your Team

Proper training ensures your team can operate and maintain the centrifugal dryer effectively. Provide hands-on training during installation and create a manual for reference.

Key Training Areas:

- Operating procedures, including startup and shutdown.

- Troubleshooting common issues, such as blockages or uneven drying.

- Maintenance tasks, such as cleaning and part replacement.

7. Monitor Performance and Make Adjustments

After integration, monitor the dryer’s performance to identify areas for improvement. Track metrics such as drying time, energy consumption, and output quality. Use this data to fine-tune the process.

Common Adjustments:

- Increasing or decreasing speed to match material flow.

- Adjusting airflow to improve drying efficiency.

- Replacing worn components to maintain performance.

8. Consider Future Upgrades

As your recycling operation grows, you may need to upgrade your centrifugal dryer or add additional units. Plan for scalability by choosing a modular system that can expand with your needs.

Conclusion

Integrating a centrifugal dryer into your plastic recycling workflow improves efficiency, reduces costs, and enhances product quality. Start by evaluating your current process, selecting the right dryer, and planning the installation. Optimize the system through regular monitoring and maintenance, and train your team to ensure smooth operation. By following these steps, you can maximize the benefits of a centrifugal dryer and streamline your recycling operations.

For more tips on improving your plastic recycling process, explore our guide to optimizing washing systems.