Otpad pjene, osobito ekspandiranog polistirena (EPS) i poliuretanske (PU) pjene, velika je briga za okoliš. Obično se koristi u pakiranju, izolaciji i raznim industrijskim primjenama, pjena nije biorazgradiva i zauzima značajan prostor na odlagalištu ako se njome ne upravlja pravilno. Strojevi za recikliranje pjene nude praktično rješenje za ovaj izazov omogućavajući recikliranje i prenamjenu otpada od pjene. Ovaj će vodič pružiti detaljan pregled strojeva za recikliranje pjene, istražujući njihove vrste, prednosti i primjene u kojima dodaju najveću vrijednost.

Što je stroj za recikliranje pjene?

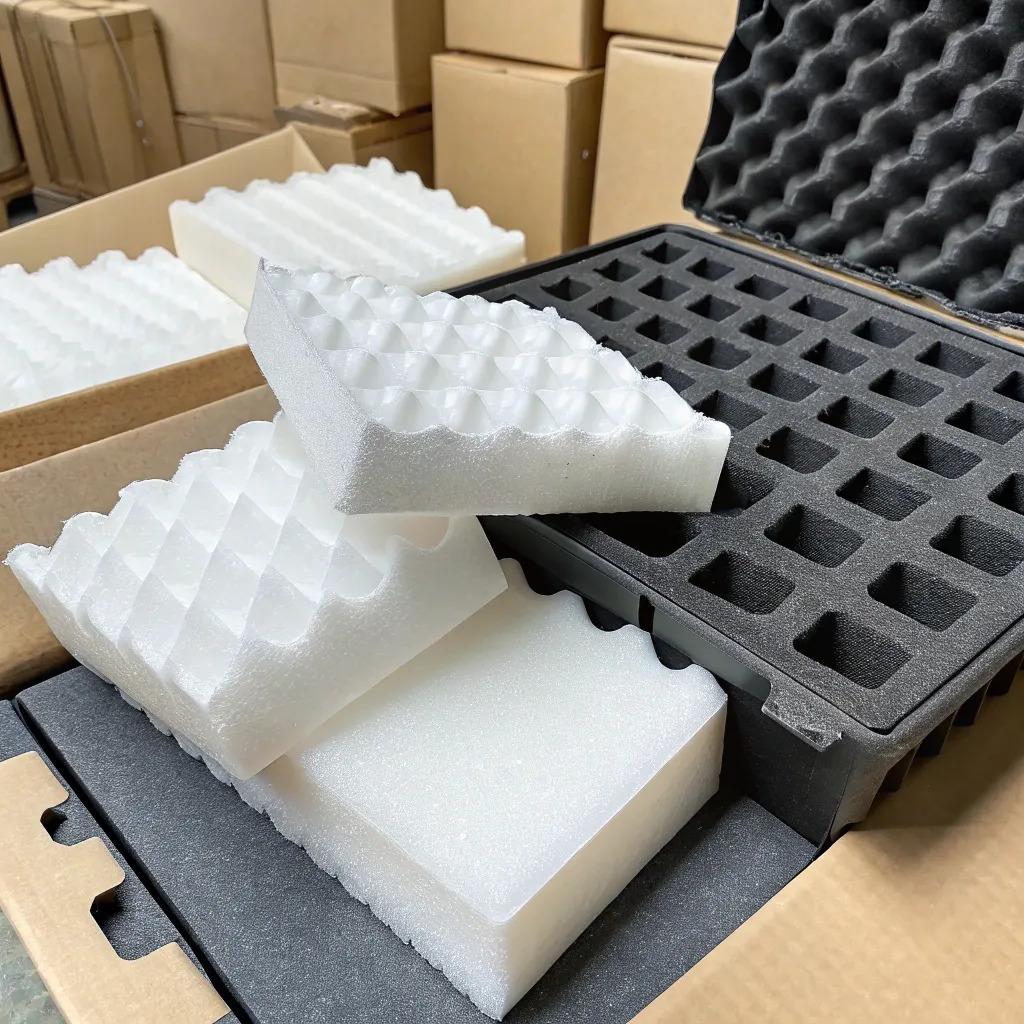

A stroj za recikliranje pjene je oprema posebno dizajnirana za obradu i recikliranje otpada od pjene. Ovi strojevi rade kompresijom ili topljenjem pjenastih materijala, omogućujući njihovu prenamjenu u nove proizvode. Recikliranje pjene smanjuje utjecaj na okoliš, štedi prostor na odlagalištima i omogućuje tvrtkama da smanje troškove gospodarenja otpadom.

Vrste strojeva za recikliranje pjene

Postoji nekoliko vrsta strojeva za recikliranje pjene, od kojih je svaka prilagođena određenim vrstama pjene i postupcima recikliranja. Razumijevanje ovih vrsta može pomoći tvrtkama da odaberu pravu opremu za svoje potrebe.

1. Hladni kompaktori

Hladni kompaktori su idealni za tvrtke koje rade s velikim količinama ekspandirane polistirenske (EPS) pjene. Stroj sabija otpadnu pjenu pomoću mehaničkog pritiska bez primjene topline, pretvarajući je u zbijene blokove. Hladno sabijanje smanjuje volumen pjene za 50-90%, čineći je lakšom i ekonomičnijom za transport.

- Najbolje za: EPS pjena i slični lagani materijali.

- Prednosti: Bez grijanja znači uštedu energije i manje operativne troškove.

- Prijave: Uobičajeno u industriji pakiranja i logistike.

2. Strojevi za vruće taljenje

Strojevi za vruće taljenje koriste toplinu za topljenje i zgušnjavanje otpada pjene. Pjena se dovodi u stroj, gdje se zagrijava dok se ne otopi, a zatim ekstrudira kao gusti blokovi ili ingoti. Ovaj proces značajno smanjuje volumen pjene, s omjerima zgušnjavanja do 90:1. Ova vrsta stroja je svestrana, radi za različite vrste pjene, uključujući EPS, XPS i EPE.

- Najbolje za: EPS, XPS i druge vrste ekspandirajućih pjena.

- Prednosti: Izlaz visoke gustoće i kompatibilnost s različitim vrstama pjene.

- Prijave: Idealno za industrije s velikim otpadom pjene, kao što je proizvodnja namještaja i uređaja.

3. Toplinski denzifikatori

Toplinski zgušnjivači funkcioniraju slično strojevima za vruće taljenje, ali se razlikuju u načinu na koji primjenjuju toplinu i zgušnjavaju pjenu. Umjesto potpunog rastapanja pjene, oni primjenjuju kontroliranu toplinu za omekšavanje i komprimiranje otpadne pjene, što olakšava transport i recikliranje.

- Najbolje za: EPS i EPE pjena.

- Prednosti: Učinkovito zgušnjavanje i mali zahtjevi za radom.

- Prijave: Koristi se u skladištima i postrojenjima za recikliranje koja upravljaju velikim količinama otpada od pjene.

4. Sjeckalice i granulatori

Sjeckalice i granulatori razbijaju pjenu u male komadiće ili granule, koje se zatim mogu ponovno upotrijebiti u drugim proizvodima ili procesima. Ovi su strojevi posebno korisni za recikliranje poliuretanske (PU) pjene, koja se obično koristi u namještaju i posteljini.

- Najbolje za: PU pjena i druge meke pjene.

- Prednosti: Reciklirana pjena može se ponovno upotrijebiti u novoj proizvodnji.

- Prijave: Uobičajeno u proizvodnji namještaja, automobilskoj industriji i industriji pakiranja.

Prednosti strojeva za recikliranje pjene

1. Ušteda troškova

Recikliranjem otpada od pjene, tvrtke mogu smanjiti troškove zbrinjavanja. Budući da je pjena lagana, ali glomazna, često zahtijeva visoke naknade za prijevoz i odlaganje otpada. Strojevi za recikliranje pjene smanjuju količinu otpada pjene, značajno smanjujući te troškove.

2. Smanjenje utjecaja na okoliš

Pjeni su potrebne stotine godina da se razgradi na odlagalištima. Ulaganjem u strojeve za recikliranje pjene, poduzeća doprinose kružnom gospodarstvu, smanjujući utjecaj na okoliš povezan s otpadom pjene.

3. Prihod od reciklirane pjene

Reciklirani blokovi i granule pjene imaju komercijalnu vrijednost jer se mogu prodati proizvođačima za upotrebu u raznim proizvodima. Ovaj dodatni izvor prihoda može pomoći nadoknaditi početno ulaganje u stroj za recikliranje.

4. Poboljšani imidž marke

Tvrtke koje aktivno sudjeluju u inicijativama za recikliranje i smanjenje otpada povećavaju reputaciju svoje marke. Mnogi potrošači danas preferiraju marke kojima je održivost prioritet, a recikliranje pjene može biti opipljiva demonstracija korporativne odgovornosti.

Primjena strojeva za recikliranje pjene

1. Ambalažna industrija

Pjena se široko koristi u pakiranju za zaštitu robe tijekom transporta. Tvrtke za pakiranje koje obrađuju velike količine otpada od pjene mogu koristiti strojeve za recikliranje kako bi pretvorile otpad u zbijene blokove, smanjujući troškove zbrinjavanja i pridonoseći inicijativama za održivo pakiranje.

2. Proizvodnja namještaja

Poliuretanska (PU) pjena uobičajena je u namještaju za oblaganje. Korištenjem drobilica ili granulatora, proizvođači namještaja mogu reciklirati otpadnu pjenu i ponovno je upotrijebiti u novom namještaju ili je prodati drugim proizvođačima.

3. Izgradnja i izolacija

Pjenasti materijali, posebno EPS i XPS, često se koriste u izolaciji i građevinarstvu. Građevinske tvrtke mogu imati koristi od strojeva za vruće taljenje i zgušnjivača za recikliranje ostataka ili otpadne pjene, koja se zatim može ponovno upotrijebiti u novim građevinskim projektima.

4. Elektronika i proizvodnja uređaja

Proizvođači uređaja često koriste pjenu za zaštitnu ambalažu. Strojevi za recikliranje pjene omogućuju tim tvrtkama preradu pjenastog otpada na licu mjesta, smanjujući troškove upravljanja otpadom i podržavajući usklađenost s ekološkim propisima.

Odabir pravog stroja za recikliranje pjene

Prilikom odabira stroja za recikliranje pjene, uzmite u obzir vrstu pjenastog otpada koji stvarate, volumen obrade i proračun. Evo ključnih čimbenika koje treba uzeti u obzir:

- Vrsta pjene: Ne rade svi strojevi sa svim vrstama pjene. Odredite je li vaš otpad EPS, PU, EPE ili neka druga vrsta pjene i odaberite stroj koji odgovara vašim potrebama.

- Količina otpada: Veće količine zahtijevaju robusnije strojeve, kao što su strojevi za vruće taljenje ili toplinski zgušnjivači, koji mogu podnijeti kontinuiranu obradu velikog kapaciteta.

- Proračun i ROI: Strojevi za recikliranje pjene imaju početne troškove, ali uštede u troškovima zbrinjavanja i potencijalni prihod od reciklirane pjene mogu ponuditi povrat ulaganja. Procijenite svoj proračun i izračunajte dugoročne uštede.

Budućnost recikliranja pjene

Budućnost recikliranja pjene vjerojatno će vidjeti napredak u tehnologiji recikliranja, sa strojevima koji će postati učinkovitiji i ekološki prihvatljiviji. Očekuje se da će više poduzeća usvojiti recikliranje pjene kao dio svojih inicijativa za održivost, potaknuto regulatornim zahtjevima i očekivanjima potrošača.

Strojevi za recikliranje pjene bitan su alat za poduzeća koja žele održivo upravljati otpadom od pjene. Razumijevanjem vrsta, prednosti i primjene ovih strojeva, tvrtke mogu donositi informirane odluke koje podržavaju njihove financijske i ekološke ciljeve.