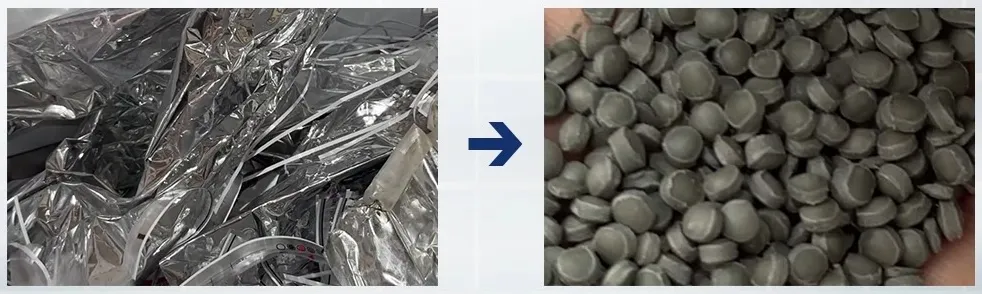

The integrated recycling machine is specifically designed to gently convert edge trims, rolls, and loose LDPE, LLDPE, HDPE, PP films, sheets, bags, and raffia waste into high-quality pellets. It is suitable for processing ordinary non-printed films, film rolls, multilayer films (such as PE/PET/PP/PA), lightly printed films, and highly printed films.

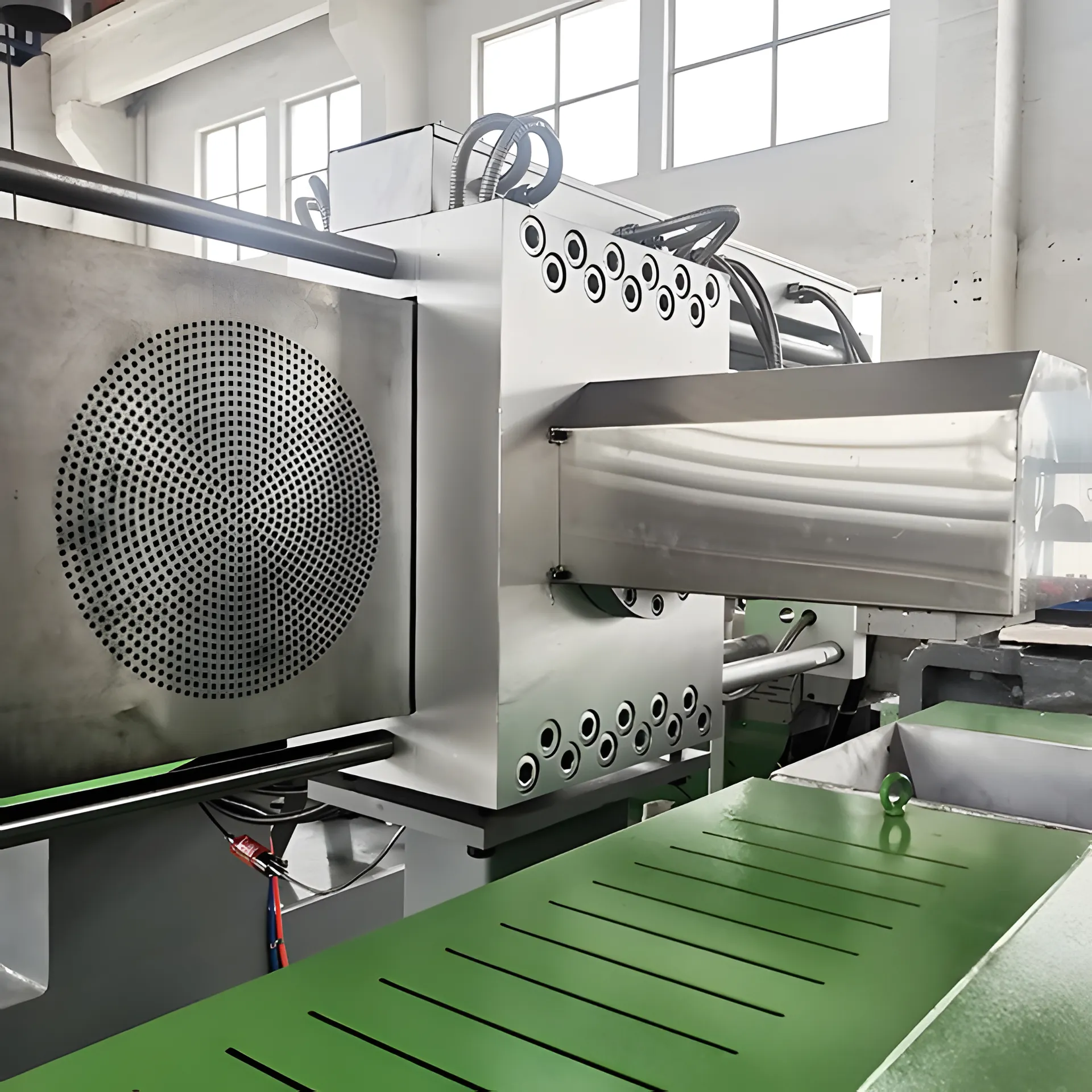

The machine’s advanced technological features include dual or triple degassing functionality in the agglomerator/cutter-compactor and an exceptional screw design combined with an extruder degassing system. These ensure thorough degassing and enhance melt homogenization efficiency. From an economic perspective, the machine not only enables the production of high-quality pellets from complex materials but also reduces energy consumption by up to 30% thanks to its energy-saving system. Additionally, its compact design further lowers production costs.

Značajka

- Combination design of agglomerator and extruder.

- Multiple screw size options.

- High-efficiency output capacity.

- Venting extruder functionality.

- Adjustable pellet size design.

- Equipped with a melt pressure sensor.

Primjena

Process Your Plastic Waste with Versatility,This innovative system is designed to handle a diverse range of plastic materials, including:

- Films: PP, PE, HDPE, LDPE, LLDPE.

- Packaging: PA66, PC, PET, OPP, BOPET.

- Fibers: ABS, Raffia, Silk, Yarn.

- Other: Foamed PE, Sheets, Food Containers, Fruit Nets, Covers.

Workflow

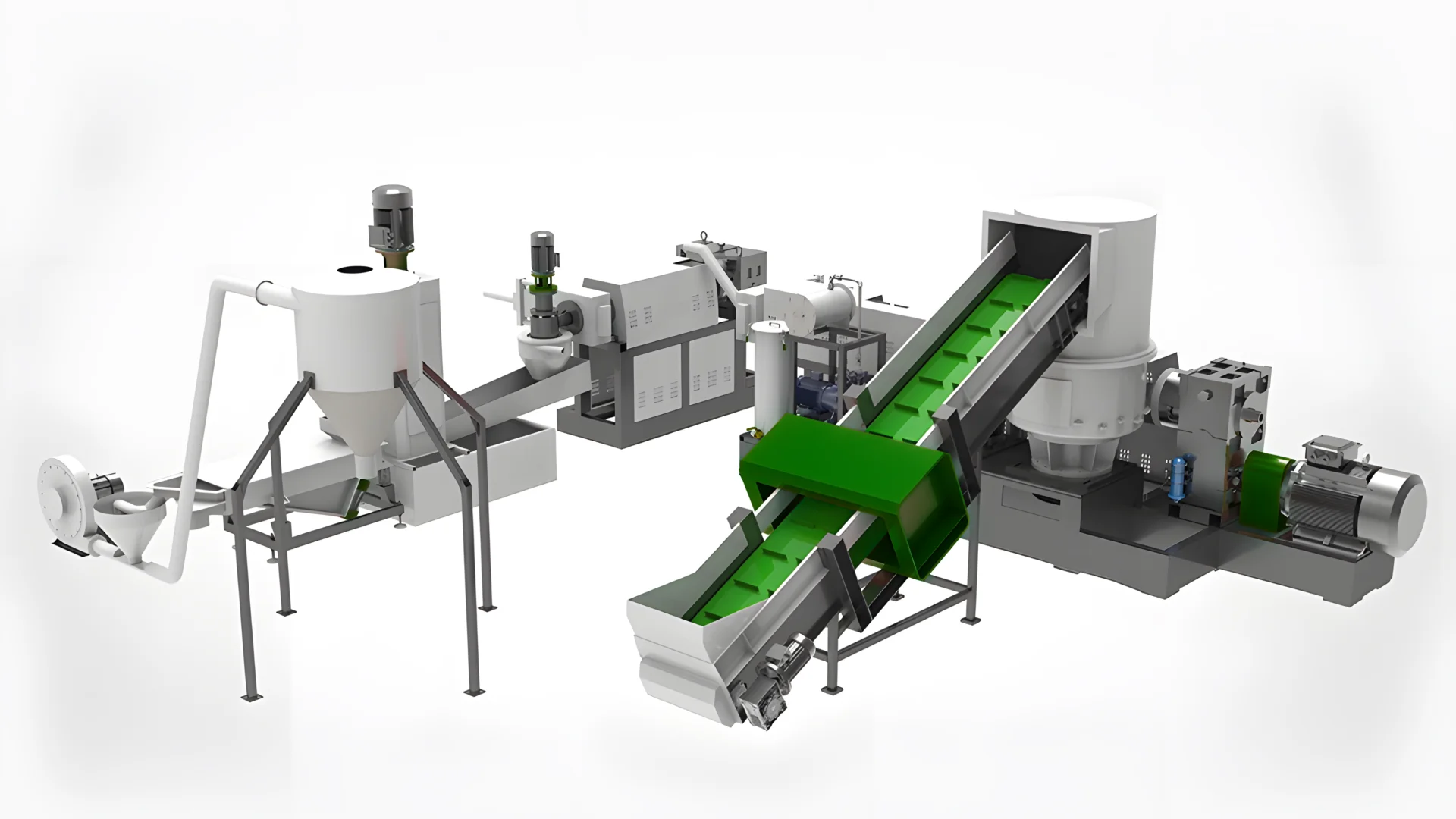

Rumtoo’s Cutter Compactor Recycling Granulating Line utilizes a multi-stage process to efficiently convert plastic waste into high-quality pellets:

- Feeding: A belt conveyor system, equipped with an optional roll hauling off device, transports plastic scraps into the compactor. An integrated metal detector ensures the removal of any metal contaminants.

- Compaction: The compactor’s rotating blades cut and compact the plastic scraps, generating frictional heat that softens the material. This pre-compaction process ensures smooth and stable feeding into the extruder.

- Extrusion: A specialized single-screw extruder gently melts and plasticizes the pre-compacted material. A double-zone vacuum degassing system effectively removes volatiles, ensuring high-quality pellets.

- Pelletizing: Water-ring die-face cutting technology precisely cuts the extruded material into uniform pellets.

- Drying: An advanced dewatering vibration sieve and horizontal-type centrifugal dewatering system efficiently dry the pellets, minimizing energy consumption.

Benefits

- High Efficiency: Process a wide range of plastic materials with high output rates (180-1500 kg/h depending on the model).

- Cost-Effectiveness: Reduce labor costs and energy consumption through automated processes and efficient drying.

- Sustainability: Transform plastic waste into valuable resources, contributing to a circular economy.

- Customization: Rumtoo offers customized solutions to meet your specific needs and material requirements.

Tehničke specifikacije:

| Model | Output ( kg/h ) |

| GL85 | 180-250 |

| GL100 | 300-400 |

| GL130 | 500-600 |

| GL160 | 700-800 |

| GL180 | 1000-1500 |

Note: Output capacity may vary depending on material type and motor configuration. Please contact Rumtoo for a personalized quotation.

Invest in a Sustainable Future:

Contact Rumtoo Machinery today to learn more about how our Cutter Compactor Recycling Granulating Line can help you transform your plastic waste into valuable resources while contributing to a greener planet.

Komentari su zatvoreni.