Industrijski sustavi za sušenje recikliranja plastike

Postignite vlažnost <3% • Povećajte protok • Maksimizirajte vrijednost

Profesionalna rješenja za odvodnjavanje i sušenje opranih plastičnih folija i krutih pahuljica - dizajnirana za stabilizaciju ekstruzije, poboljšanje kvalitete peleta i smanjenje operativnih troškova.

Sušenje je posljednji pokazatelj kvalitete prije peletiranja

Većina linija za recikliranje mehanički uklanja višak vode (cijeđenjem ili centrifugalnom sušilicom) prije konačnog sušenja vrućim zrakom. Pravilna kontrola vlage osigurava stabilnu ekstruziju i veću vrijednost peleta. Ako planirate ekstruziju nakon sušenja, pogledajte Peletizatori plastike.

Tehnologija za vrhunske performanse

Visokoučinkovito odvodnjavanje i sušenje

Naši sustavi su dizajnirani za kontinuirani, teški rad, rukovanje različitim vrstama plastike i pružanje vodeće suhoće u industriji za pripremu materijala za visokokvalitetno peletiranje.

-

Precizna kontrola vlage

Postići konačni sadržaj vlage od samo 1-3% za filmove i ispod 2% za krute pahuljice.

-

Mehanička i termička rješenja

Od centrifugalne sile do termičkog sušenja, nudimo pravu tehnologiju za vaš specifični materijal i budžet.

Napredna integracija sustava

Svaki stroj je konstruiran tako da se besprijekorno integrira u postojeće linije za pranje, povećavajući ukupnu učinkovitost procesa i protok.

-

Svestranost materijala

Optimizirano za širok raspon materijala, uključujući PE/PP folije, PET pahuljice i krute HDPE/PP plastike.

-

Dizajni koji štede energiju

Mehanički sustavi za odvodnjavanje nude isplativu alternativu termalnim sušilicama, smanjujući operativne troškove.

Povećana propusnost

Učinkovitim uklanjanjem vode, naši sustavi sprječavaju uska grla u proizvodnji i povećavaju učinak cijele vaše linije.

Poboljšana kvaliteta peleta

Pravilno osušen materijal uklanja nedostatke u konačnim peletima, što dovodi do krajnjeg proizvoda veće vrijednosti.

Istražite naše sustave za sušenje

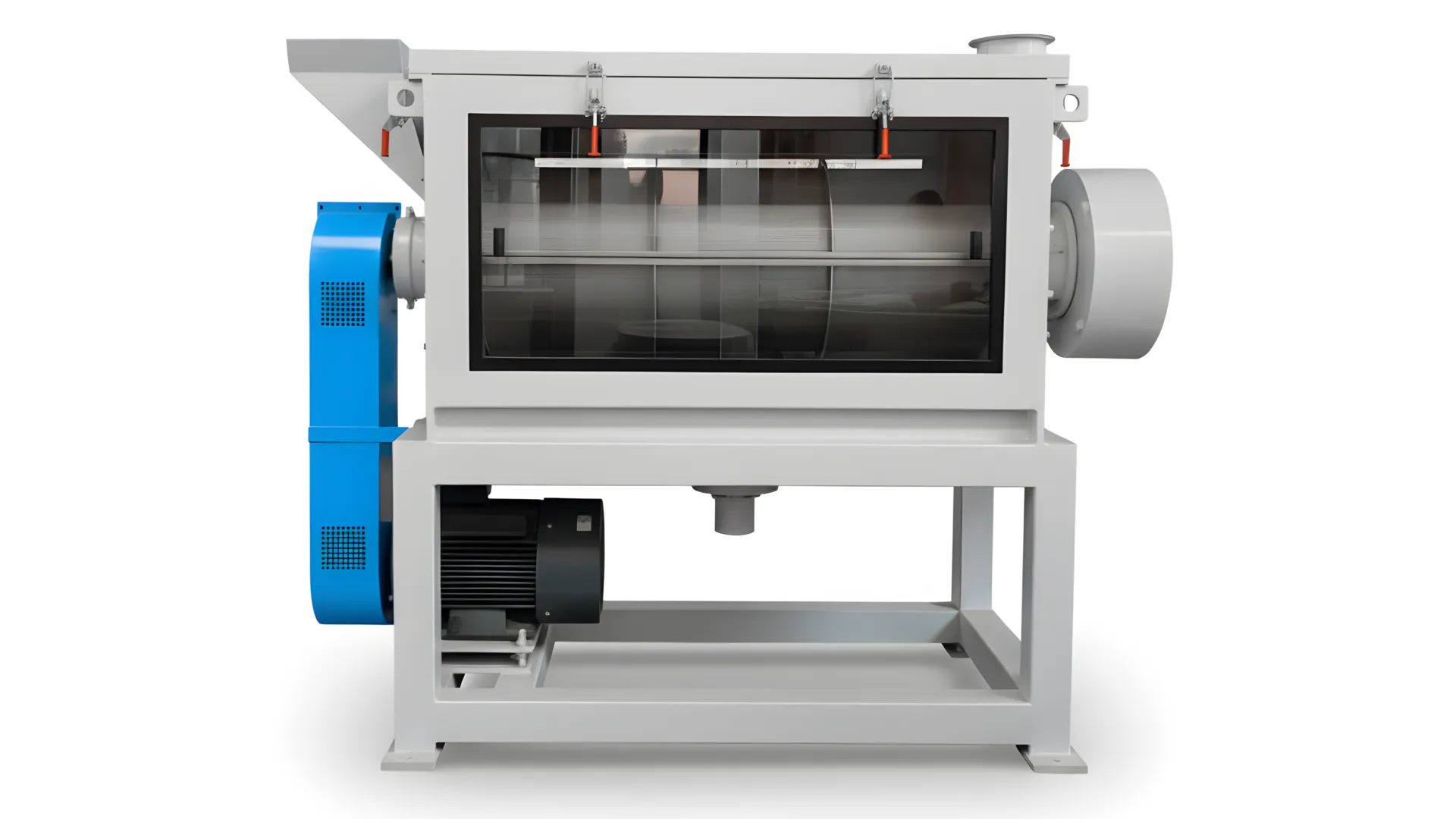

Cjedilo i zgušnjivač plastične folije

Vrhunsko rješenje za odvodnjavanje i zgušnjavanje opranih filmova. Mehanički smanjuje vlagu na 1-5% i pretvara glomazni materijal u guste, lako usisane grudice.

Centrifugalna sušilica za krute pahuljice

Brzi, energetski učinkovit stroj koji brzo smanjuje vlagu u krutim pahuljicama (PET, PP, PE) na ispod 2% koristeći snažnu centrifugalnu silu za završno ispiranje i sušenje.

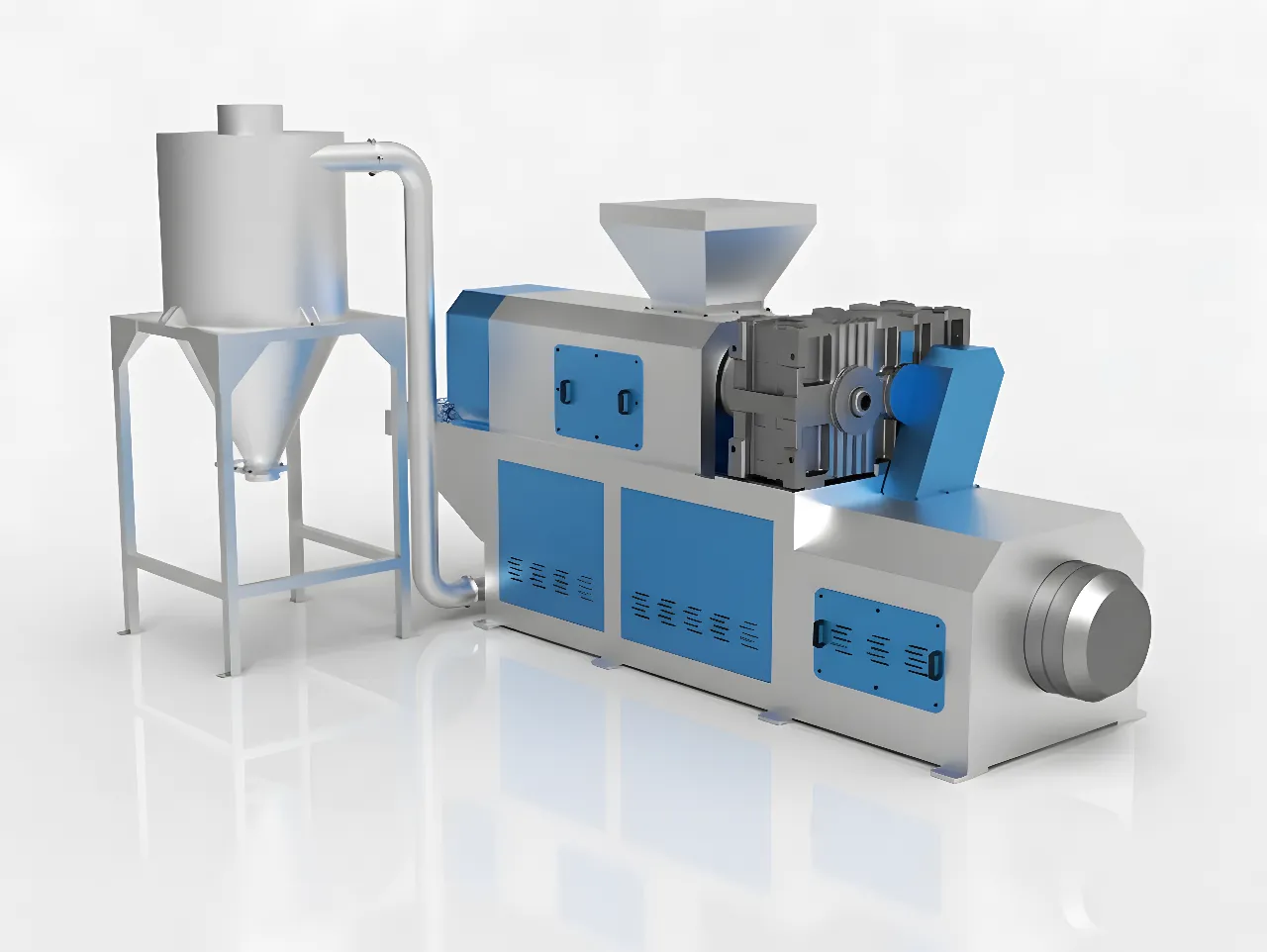

Termalna sušilica za recikliranje plastike

Visokoučinkovito rješenje za linije za folije i PET. Pomoću vrućeg zraka i ciklonskog separatora učinkovito smanjuje sadržaj vlage na ispod 3% za čist i suh izlaz.

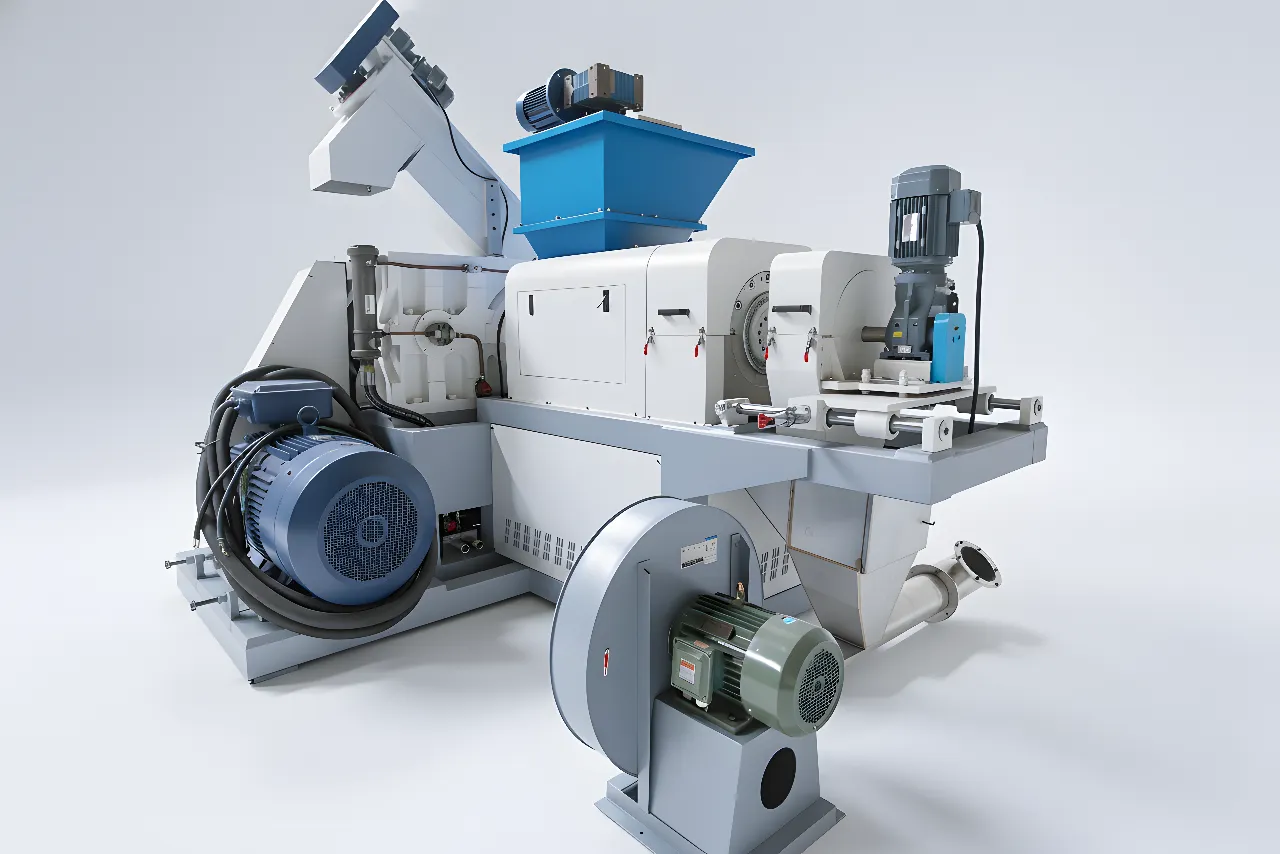

Sustav za odvodnjavanje pužnom prešom

Projektiran za linije za pranje PE folija, ovaj stroj učinkovito ekstrahira vlagu ispod 15%, nudeći isplativu alternativu termalnim sušilicama.

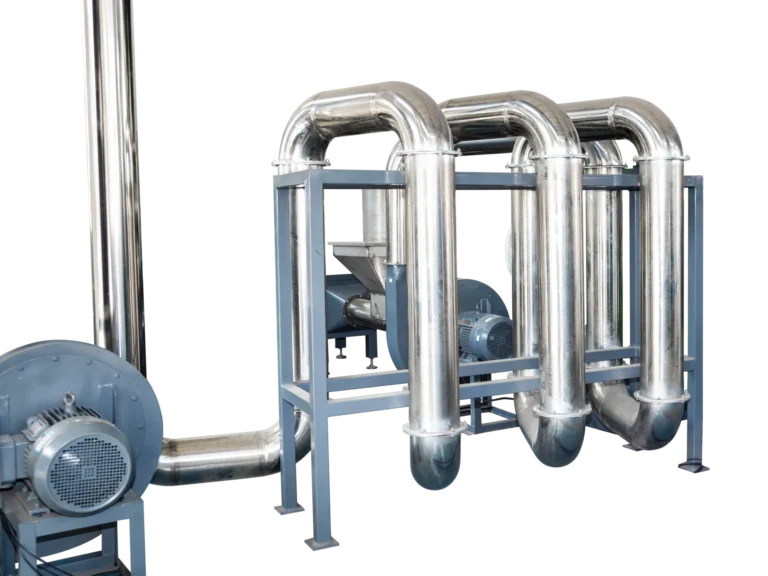

Sustav sušenja vrućim zrakom u cjevovodu

Teški sustav za krute plastike (PET, HDPE, PP) koji jamči konačni sadržaj vlage manji od 2%, povećavajući protok i vrijednost materijala.

Frikcijska podloška velike brzine

Učinkovito uklanja vlagu iz raznih plastičnih materijala, poboljšavajući kvalitetu proizvoda, povećavajući učinkovitost obrade i štedeći energiju.

Mjerljive koristi

Veća vrijednost materijala

Vrhunska cijena s dosljedno niskim udjelom vlage.

Niži operativni troškovi

Mehaničko odvodnjavanje značajno štedi troškove energije u usporedbi s termičkim sušenjem.

Povećane stope proizvodnje

Povećajte protok sprječavanjem uskih grla u vašoj liniji za pranje rublja.

Manje nizvodnih nedostataka

Uklonite probleme uzrokovane vlagom u procesima ekstruzije i oblikovanja.

Često postavljana pitanja

Koja je razlika između mehaničkog i termičkog sušenja?

Mehaničko odvodnjavanje (poput cijeđenja ili centrifugalne sušilice) koristi fizičku silu za uklanjanje većine vode - vrlo je energetski učinkovito. Termičko sušenje koristi zagrijani zrak za isparavanje preostale vlage na najniže moguće razine, što je ključno za materijale poput PET-a.

Koji je sustav sušenja pravi za moj plastični materijal?

Ovisi o vašem materijalu i ciljanoj vlažnosti. Za meke PE/PP folije, stiskalica za folije često je najbolje rješenje "sve u jednom". Za krute pahuljice poput PET-a koje zahtijevaju vrlo nisku vlažnost, idealna je kombinacija centrifugalne sušilice i sustava vrućeg zraka u cjevovodu.

Koju konačnu razinu vlage mogu očekivati?

Naši sustavi su dizajnirani za vrhunske performanse. Možete očekivati razinu vlage od 1-5% za filmove obrađene stiskalicom, a ispod 2% za krute pahuljice obrađene našim naprednim centrifugalnim i termičkim sustavima, osiguravajući da je vaš materijal spreman za visokokvalitetno peletiranje.

Možete li projektirati kompletnu liniju za pranje, sušenje i peletiranje?

Da. Projektiramo sustave recikliranja po principu "ključ u ruke" na temelju vašeg materijala, razine kontaminacije, ciljane vlažnosti i učinka. Oprema za sušenje odabire se kao dio kompletne linije kako bi se osigurala stabilna ekstruzija i dosljedna kvaliteta peleta.

Spremni za optimizaciju procesa sušenja?

Kontaktirajte naše stručnjake kako biste razgovarali o vrsti vašeg materijala, ciljanoj razini vlage i zahtjevima za protok. Preporučit ćemo najučinkovitiju konfiguraciju sušenja i dati konkurentnu ponudu. Za projekte po principu "ključ u ruke", od pranja do peletiranja, počnite s Rješenja za recikliranje.

Zatražite besplatnu ponudu