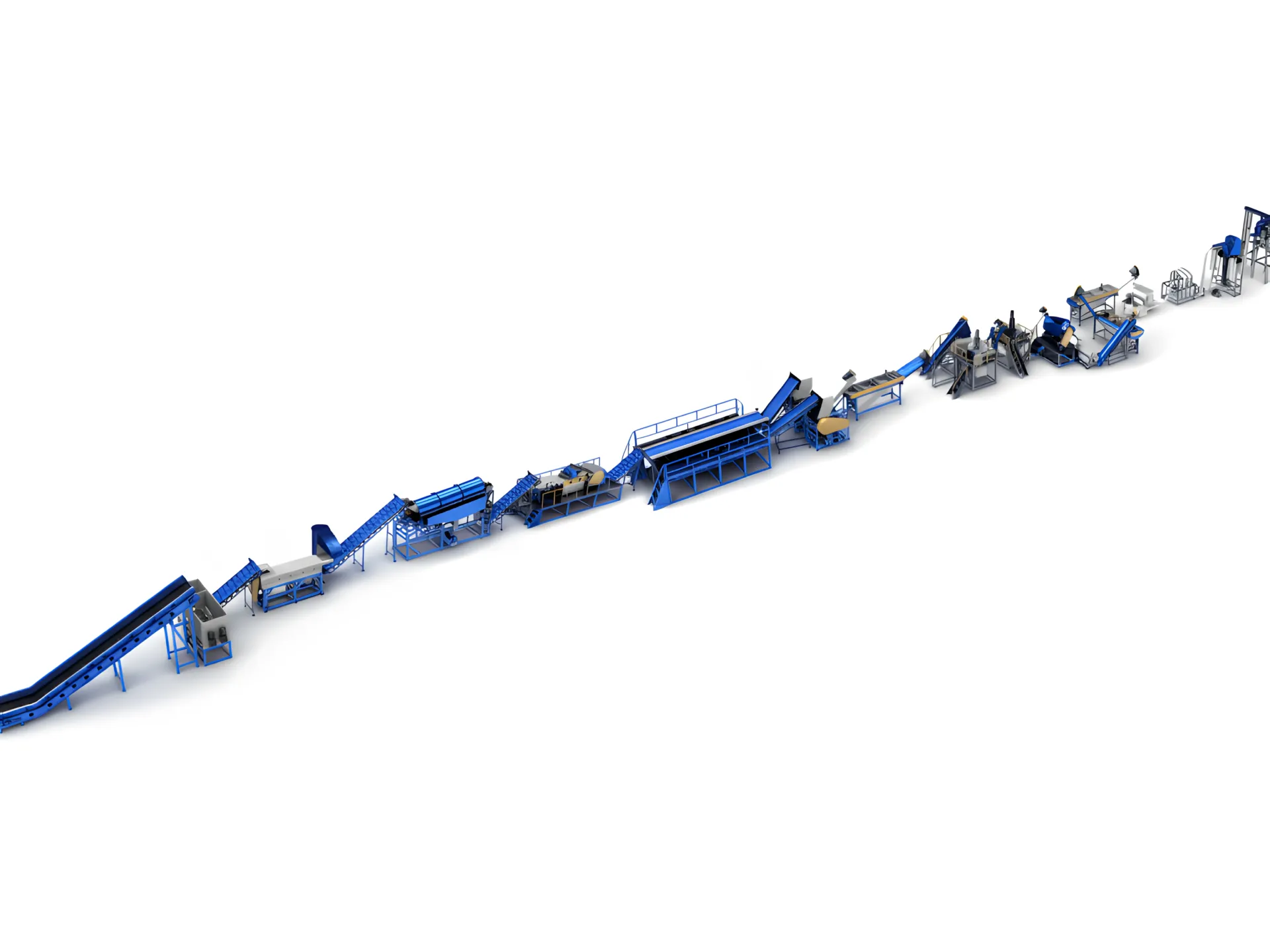

Linija za pranje i recikliranje krute plastike HDPE i PP

Pretvorite glomazni HDPE/PP otpad - poput boca, sanduka, bačvi i cijevi - u čiste, visokovrijedne reciklirane pahuljice. Naša potpuno automatizirana linija projektirana je za visoku propusnost, vrhunsko čišćenje i maksimalnu učinkovitost.

Pretvorite otpad u vrijednu robu

Ulaganje u našu liniju za recikliranje pametan je izbor za vaše poslovanje i planet. Stvorite novi izvor prihoda od plastičnog otpada, a istovremeno ostvarite svoje ciljeve održivosti.

Izlaz visoke kvalitete

Naš višestupanjski proces pranja i pročišćavanja pažljivo uklanja onečišćujuće tvari poput prljavštine, etiketa i ljepila, proizvodeći čiste, konzistentne pahuljice pogodne za širok raspon proizvodnih primjena.

Automatizirana učinkovitost

Dizajniran za visoku propusnost i pouzdanost, naš pojednostavljeni proces od usitnjavanja do sušenja potpuno je automatiziran kako bi se smanjilo vrijeme zastoja, smanjili troškovi rada i maksimizirao vaš operativni učinak.

Ekonomska i ekološka prednost

Pretvorite odgovornost za otpad u vrijednu imovinu. Proizvodite isplative reciklirane pahuljice koje smanjuju potražnju za djevičanskom plastikom, čuvaju prirodne resurse i značajno smanjuju vaš ugljični otisak.

Od glomaznog otpada do čistih pahuljica: Proces

Smanjenje veličine

Glomazne krute plastike se ubacuju u snažan drobilicu i granulator, gdje se usitnjavaju na male, jednolične pahuljice.

Pranje i odvajanje

Pahuljice se intenzivno čiste u peračima trenjem i pročišćavaju se u spremnicima s plutajućim sudoperom kako bi se uklonile onečišćujuće tvari.

Sušenje

Stroj za odvodnjavanje i termalna sušilica rade zajedno kako bi uklonili vlagu, postižući konačnu razinu vlažnosti idealnu za skladištenje ili prodaju.

Kolekcija

Čiste, suhe pahuljice skupljaju se u silosu za skladištenje, često sa sustavom za uklanjanje prašine, spremne za pakiranje i ponovnu upotrebu.

Ključni moduli linije za recikliranje

Naše linije za recikliranje su modularne i mogu se prilagoditi vašim specifičnim zahtjevima za ulaznim materijalima i izlazom. Tipična visokoučinkovita linija uključuje:

Primarno smanjenje veličine

Robusni šreder s jednom osovinom, nakon kojeg slijedi drobilica (granulator), učinkovito usitnjava glomazne predmete u jednolične pahuljice, pripremajući ih za proces pranja. Naši šrederi imaju velike komore i brze hidraulične klipove za maksimalni protok.

Intenzivni sustav pranja

Brza peračica trenjem riba ljuskice kako bi uklonila prljavštinu i ostatke s površine. Za jako zaprljane materijale može se integrirati opcionalni sustav vrućeg pranja kako bi se razgradile tvrdokorne nečistoće poput ulja i ljepila.

Sustav za pročišćavanje

Spremnik s plutajućim sustavom koristi gustoću vode za izvođenje ključnog koraka odvajanja. Omogućuje vrijednim HDPE/PP pahuljicama da plutaju, dok teži onečišćujući materijali (PET, PVC, metal, staklo) tonu i uklanjaju se iz sustava.

Visokoučinkoviti sustav sušenja

Centrifugalni stroj za odvodnjavanje prvo mehanički uklanja većinu površinske vode. Naknadni termalni sustav sušenja cijevi koristi vrući zrak za smanjenje konačnog sadržaja vlage na manje od 1%, osiguravajući da su pahuljice spremne za visokokvalitetno peletiranje ili proizvodnju.

Tehničke specifikacije i potrošnja

| Opcije kapaciteta | 500 kg/h do 2000 kg/h |

|---|---|

| Primjenjivi materijali | HDPE, PP (boce, sanduci, cijevi, bačve itd.) |

| Konačni proizvod | Čiste, visokočiste plastične pahuljice |

| Konačni sadržaj vlage | < 1% |

| Kontrolni sustav | Automatizirani PLC s HMI-jem |

| Struja | ~ 50 - 80 kWh / tona |

|---|---|

| Voda | ~ 0,8 - 1,5 tona / tona (standardna recirkulacija) |

| Komprimirani zrak | ~ 0,5 - 1 m³ / tona |

| Deterdžent (opcionalno) | ~ 2 - 4 kg / tona |

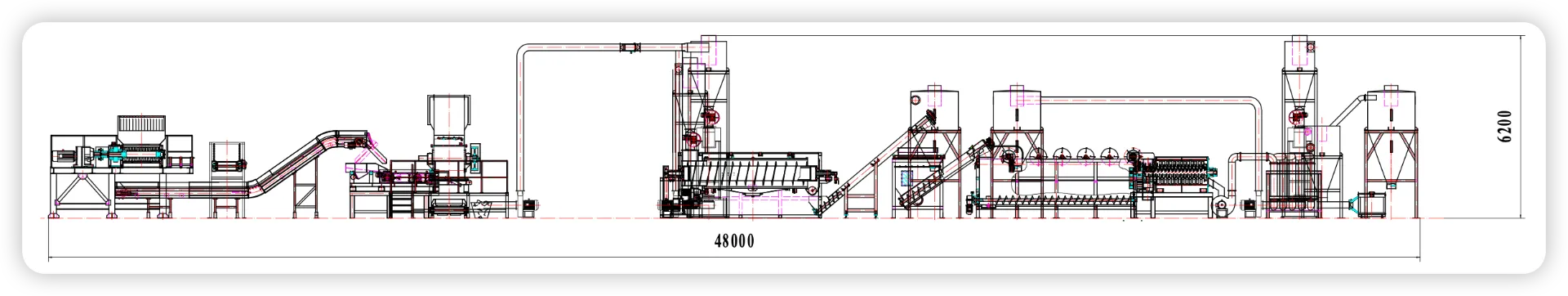

Dijagram rasporeda sustava

Često postavljana pitanja

Kakva je kvaliteta konačnih recikliranih plastičnih pahuljica?

Naš sustav je dizajniran za proizvodnju pahuljica visoke čistoće. Uz pravilno sortiranje i opcionalni sustav vrućeg pranja, konačni proizvod može postići razinu kvalitete pogodnu za proizvodnju novih cijevi, spremnika, automobilskih dijelova i još mnogo toga, često konkurirajući djevičanskim materijalima u određenim primjenama.

Koliko vode troši linija za recikliranje?

Iako pranje zahtijeva vodu, naše su linije dizajnirane imajući na umu učinkovitost. Svi naši sustavi uključuju recirkulaciju i filtraciju vode, što značajno smanjuje potrošnju svježe vode na otprilike 0,8-1,5 tona po toni prerađene plastike.

Može li se ova linija prilagoditi mojim specifičnim potrebama?

Apsolutno. Naše linije su potpuno modularne. Možemo prilagoditi kapacitet (od 500 do 2000 kg/h), dodati ili ukloniti određene module (poput vrućeg pranja ili drugog spremnika s plutajućim sudoperom) i konfigurirati raspored kako bi odgovarao prostoru vašeg pogona i razini kontaminacije vašeg materijala.

Surađujte s nama za vaše potrebe recikliranja

Svi naši strojevi za recikliranje dolaze s sveobuhvatnim jednogodišnjim ograničenim jamstvom. Kontaktirajte nas još danas kako biste razgovarali o svom projektu, dobili trenutne cijene i prilagođeni raspored za vaše poslovanje.