Vijesti o recikliranju

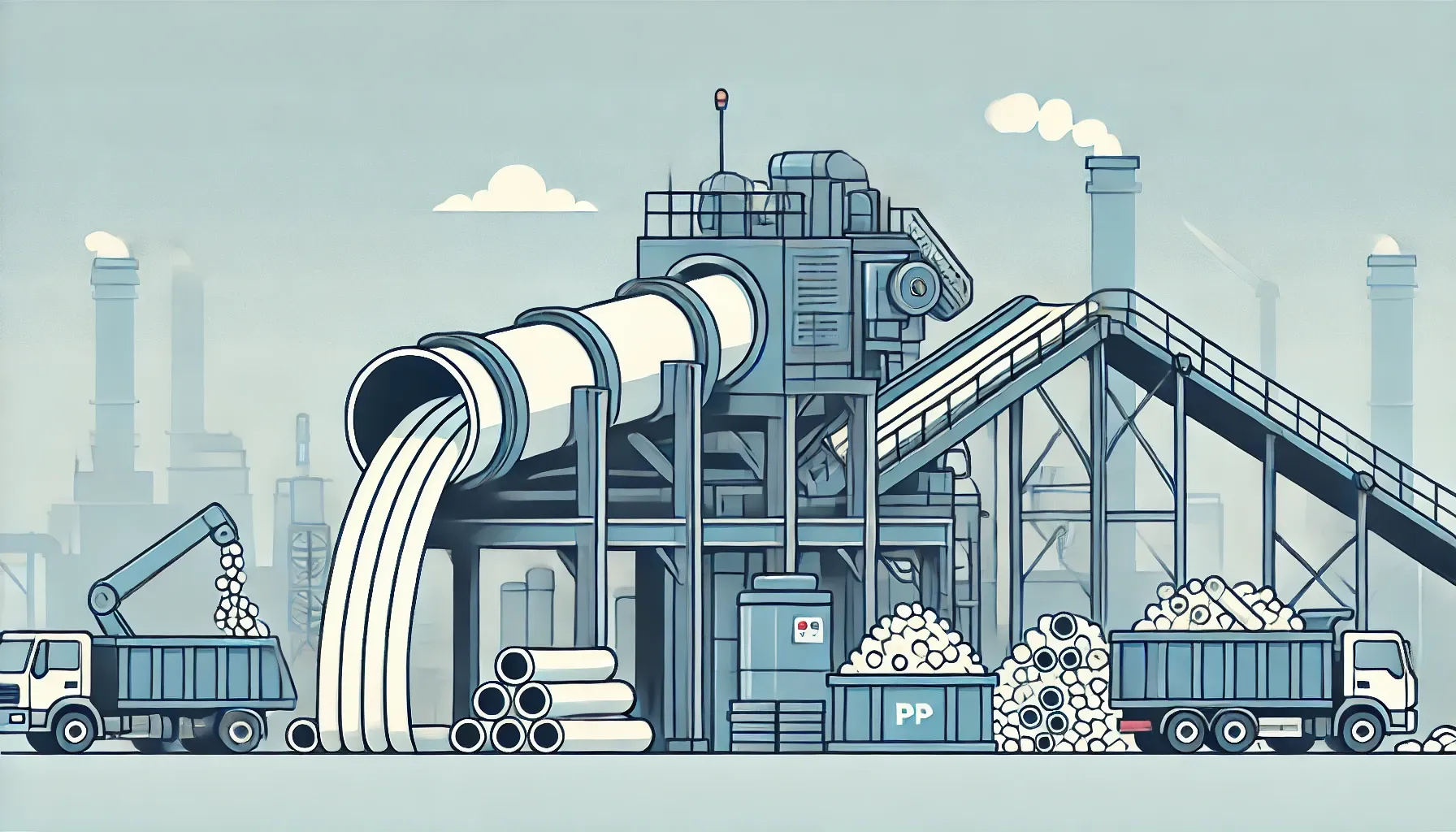

Napredna rješenja za obradu plastičnih cijevi

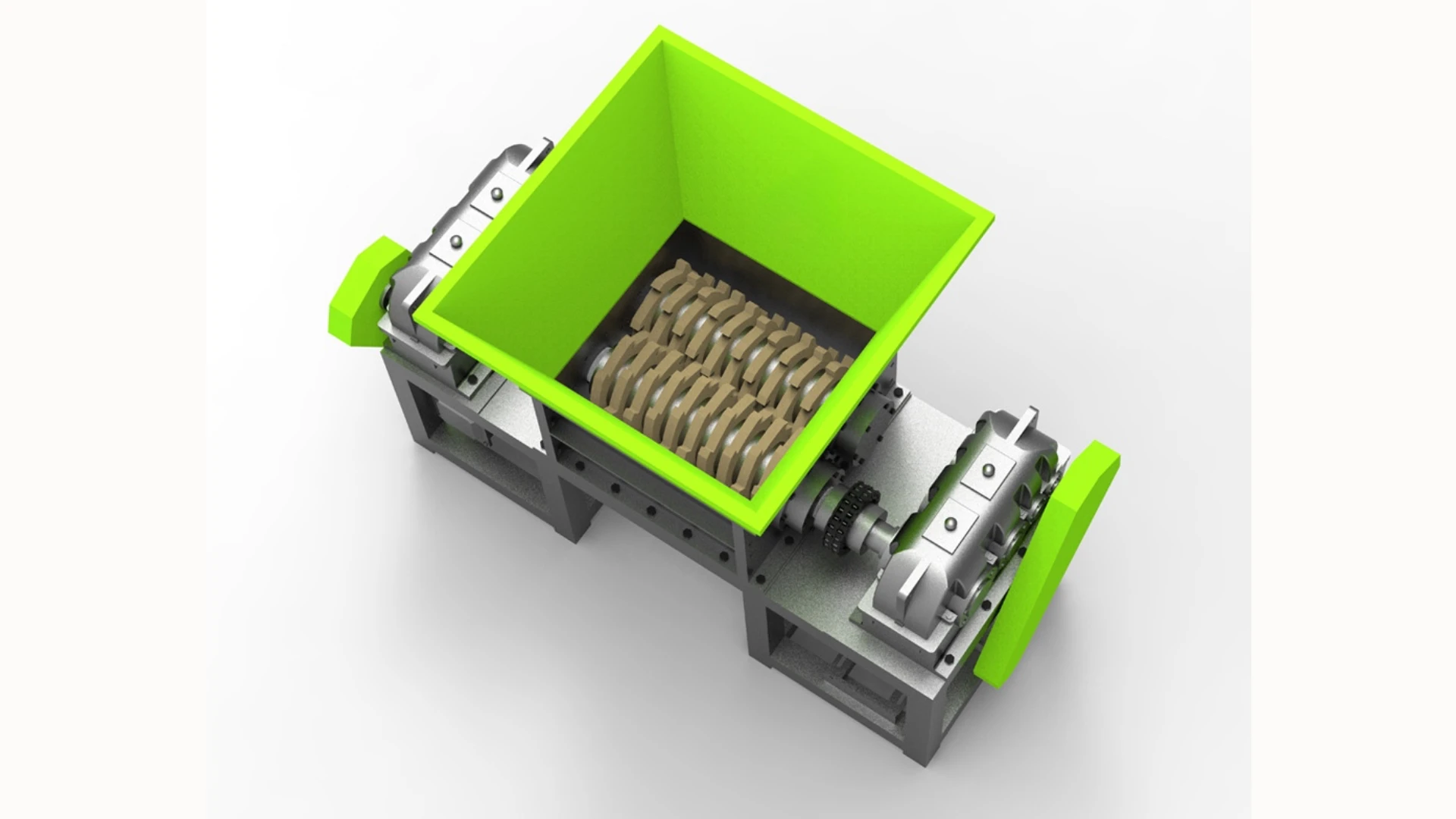

Rumtoo nudi niz rješenja za obradu plastičnih cijevi, uključujući usitnjavače s jednom osovinom s vertikalnim dovodom i vodoravne usitnjavače za duge dijelove cijevi. Više od polovice od 50 najboljih ekstrudera za cijevi, profile i cijevi oslanja se na Rumtoo opremu za recikliranje.

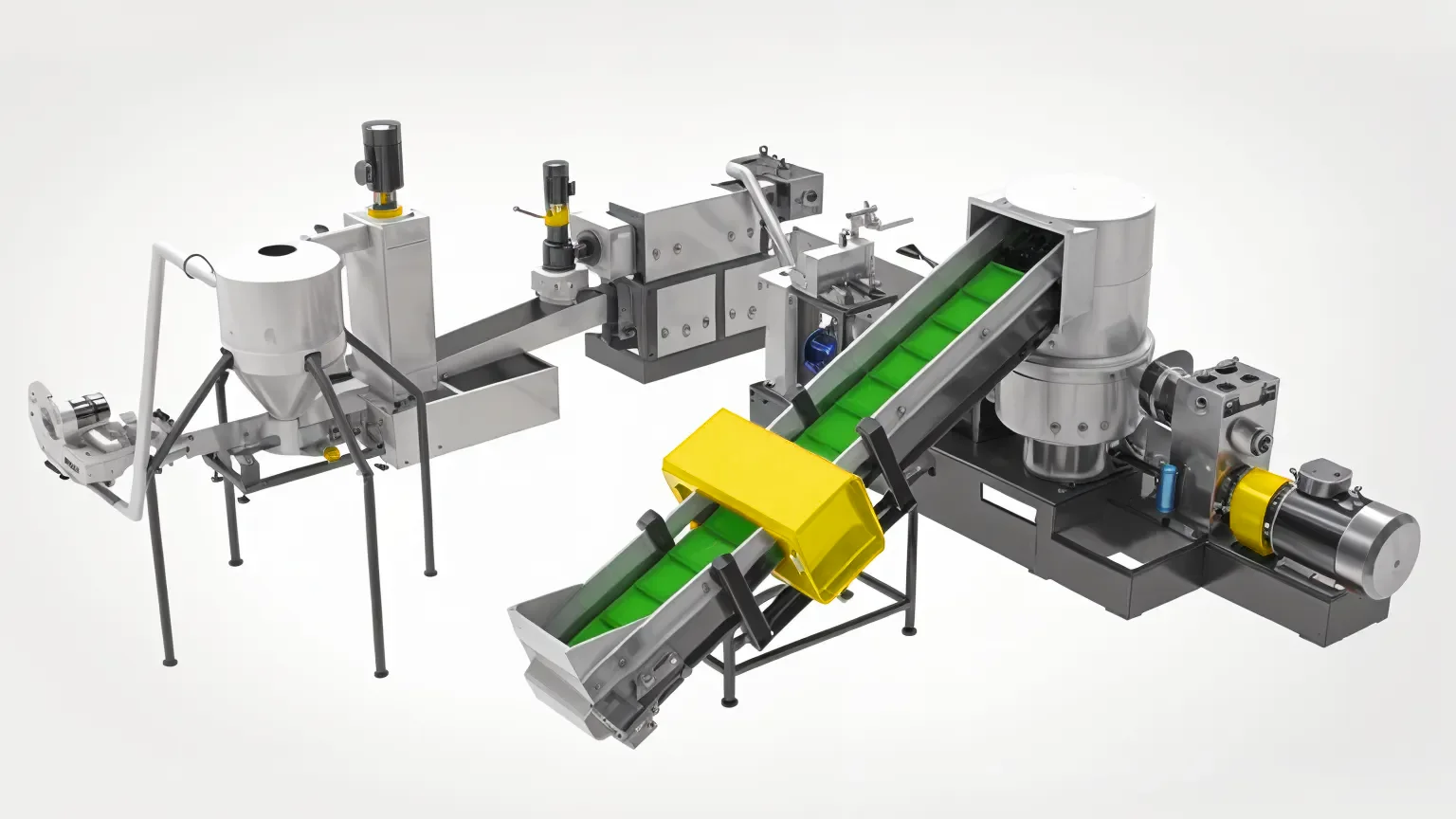

Plastic pelletizer machines are crucial in the plastics industry, turning raw plastic materials into pellets that can be used for manufacturing various products. If you're considering investing in one, it's important to understand the factors that influence their cost. This article delves into the key elements affecting the pricing of plastic pelletizer machines, including machine specifications, production capacity, and brand reputation.

When it comes to purchasing a plastic pelletizer machine, potential buyers are often faced with a variety of choices, ranging from budget-friendly models to high-end options. This guide provides an in-depth review of different models available in the market, highlighting their features, advantages, and price points to help you make an informed decision.

Tehnologija bez premca u usitnjavanju filma i vlakana

Rumtoo, svjetski lider u opremi za uništavanje filmova, nudi uništavače serije RTM, jedine strojeve opremljene patentiranim sustavom rezanja. Ovaj revolucionarni dizajn prevladava uobičajene probleme s kojima se suočavaju tradicionalni brusilice za film i vlakna, kao što su samodostavljanje i omatanje rotora. Sustav osigurava precizne rezove i velike nasipne gustoće, što ga čini bitnom komponentom učinkovitih sustava za povrat smole u obliku filma koji se danas koriste.

Jedini izbor za recikliranje filmova i vlakana

Kada je riječ o strojevi za rezanje filma, Rumtoo's RTM Series stands out. With the unique technology, these shredders deliver unparalleled performance in film and fiber recycling. Rumtoo's expertise in size reduction is evident in the quality and reliability of their equipment.

Svestrana rješenja za povećanje potreba za recikliranjem

As the recycling industry evolves, Rumtoo's film and fiber shredders are designed to handle an increasing variety of plastic and fiber scrap materials. From highly tear-resistant synthetic fibers to textiles and ropes, Rumtoo grinders efficiently process even the toughest materials. The latest advancements, including the film and fiber rotor, ensure these machines meet the highest standards in plastic grinding technology.

Pronađite svoj savršeni sustav za obnavljanje filma i vlakana

Explore Rumtoo's innovative solutions and find the film and fiber recovery system that fits your needs. Contact Rumtoo today to discover how their cutting-edge shredders can enhance your recycling operations.

Introduction to Plastic Container Recycling

Plastic bottles, buckets, barrels, drums, IBCs (intermediate bulk containers), totes, and tanks are ubiquitous in various industries due to their durability and reusability. However, these containers eventually become damaged, contaminated, or simply wear out. When they reach the end of their lifecycle, recycling becomes essential. The first crucial step in the recycling process is size reduction, a field where Rumtoo excels.

When it comes to PET bottle recycling, Rumtoo's industrial shredders are leading the way. These machines are specifically designed to handle the complexities of recycling plastic bottles, providing an efficient and reliable solution for plastic container recycling. Often referred to as PET bottle shredders or PET bottle grinders, Rumtoo's shredding technology is at the forefront of plastic waste management.

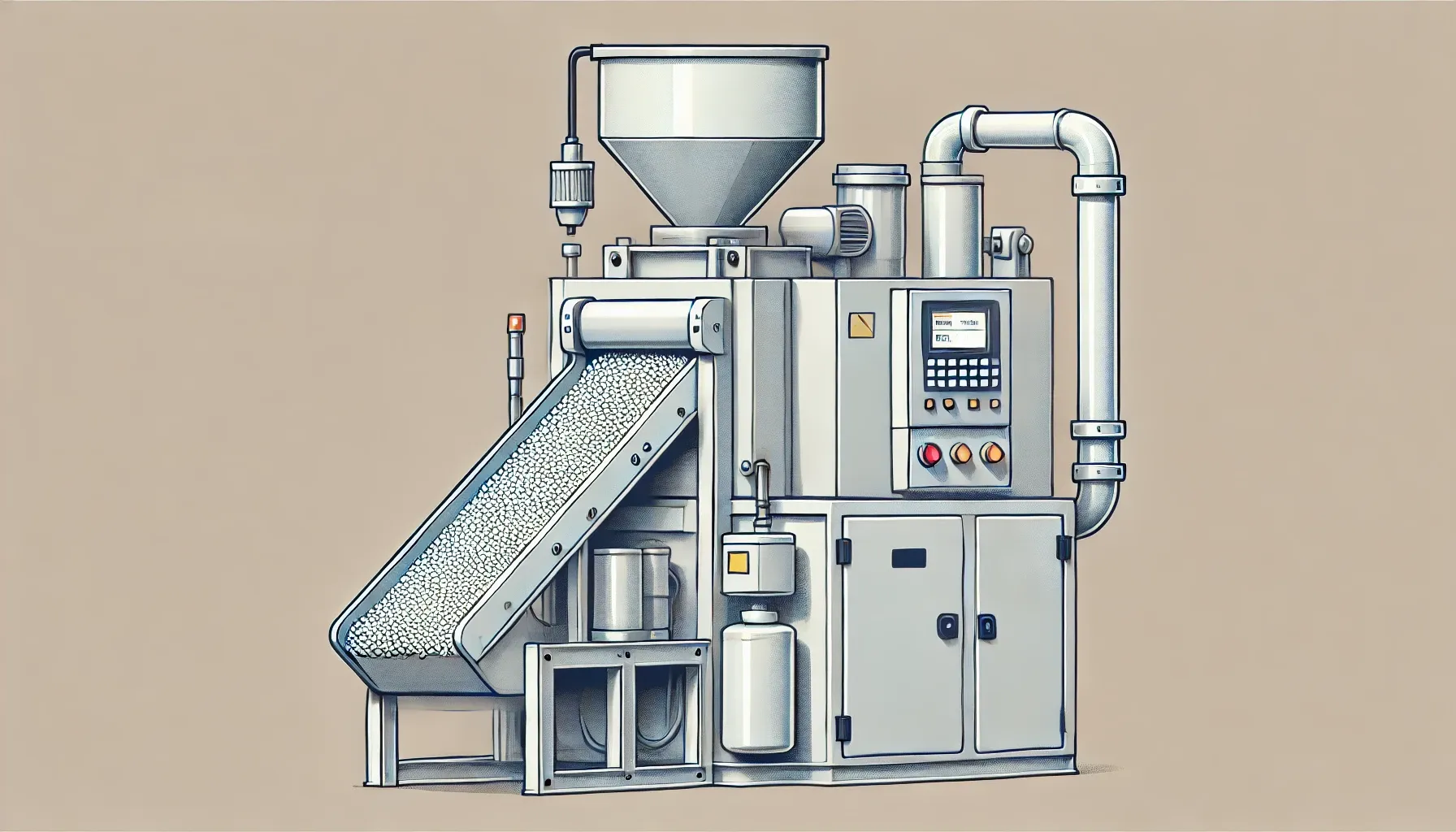

Uvod u plastične peletizere

Peletizator plastike ključni je stroj u industriji recikliranja i proizvodnje, dizajniran za pretvorbu plastičnog otpada u upotrebljive plastične kuglice. Ovi peleti služe kao sirovina za proizvodnju novih plastičnih proizvoda, čineći peletizator ključnim igračem u promicanju održivih praksi.

In today's world, where plastic waste is a growing concern, recycling has become more crucial than ever. One of the key components in the plastic recycling process is the granulator, a machine that breaks down plastic waste into smaller, more manageable pieces called granules. These granules can then be reused to create new plastic products, reducing the need for virgin plastic and minimizing the environmental impact of plastic waste.

However, not all plastic granulators are created equal. There are various types of granulators designed to handle different kinds of plastic waste and cater to specific recycling needs. In this article, we'll explore the different types of plastic granulators and help you determine which one suits your recycling needs best.

Plastic granulators play a pivotal role in the plastic recycling process, transforming plastic waste into small, uniform granules that can be reused in manufacturing new plastic products. To ensure your plastic granulator operates at peak efficiency and enjoys a long operational life, it is essential to implement a robust maintenance routine and address any issues promptly.

In recent years, the recycling industry has witnessed a surge of innovations in plastic granulators that are transforming the way we process and recycle plastic waste. These cutting-edge advancements are not only improving the efficiency and performance of granulators but also contributing to a more sustainable future. In this article, we will explore some of the most significant innovations in plastic granulators and how they are revolutionizing the recycling industry.

The Importance of Plastični granulatori in Recycling

Plastic granulators play a crucial role in the recycling process by reducing large plastic waste into smaller, more manageable pieces known as granules. These granules can then be easily sorted, cleaned, and reprocessed into new plastic products. Granulators are essential for efficiently handling the ever-growing amount of plastic waste generated by our society.

The Need for Innovation in Plastic Granulators

As the demand for recycled plastic increases, so does the need for more advanced and efficient plastic granulators. Traditional granulators often face challenges such as high noise levels, energy consumption, and maintenance requirements. Additionally, the increasing complexity of plastic waste streams requires granulators to adapt and handle a wider range of materials effectively.

Noise Reduction Technologies

One of the most significant advancements in plastic granulators is the development of noise reduction technologies. Granulators are known for their high noise levels, which can be a concern for workers and neighboring communities. However, innovative designs and materials are now being used to minimize noise pollution.

Soundproofing Materials and Enclosures

Manufacturers are incorporating soundproofing materials, such as acoustic foams and insulation, into the construction of granulators. These materials absorb and dampen sound waves, significantly reducing the noise emitted by the machines. Additionally, some granulators are equipped with soundproof enclosures that further contain the noise, creating a quieter working environment.

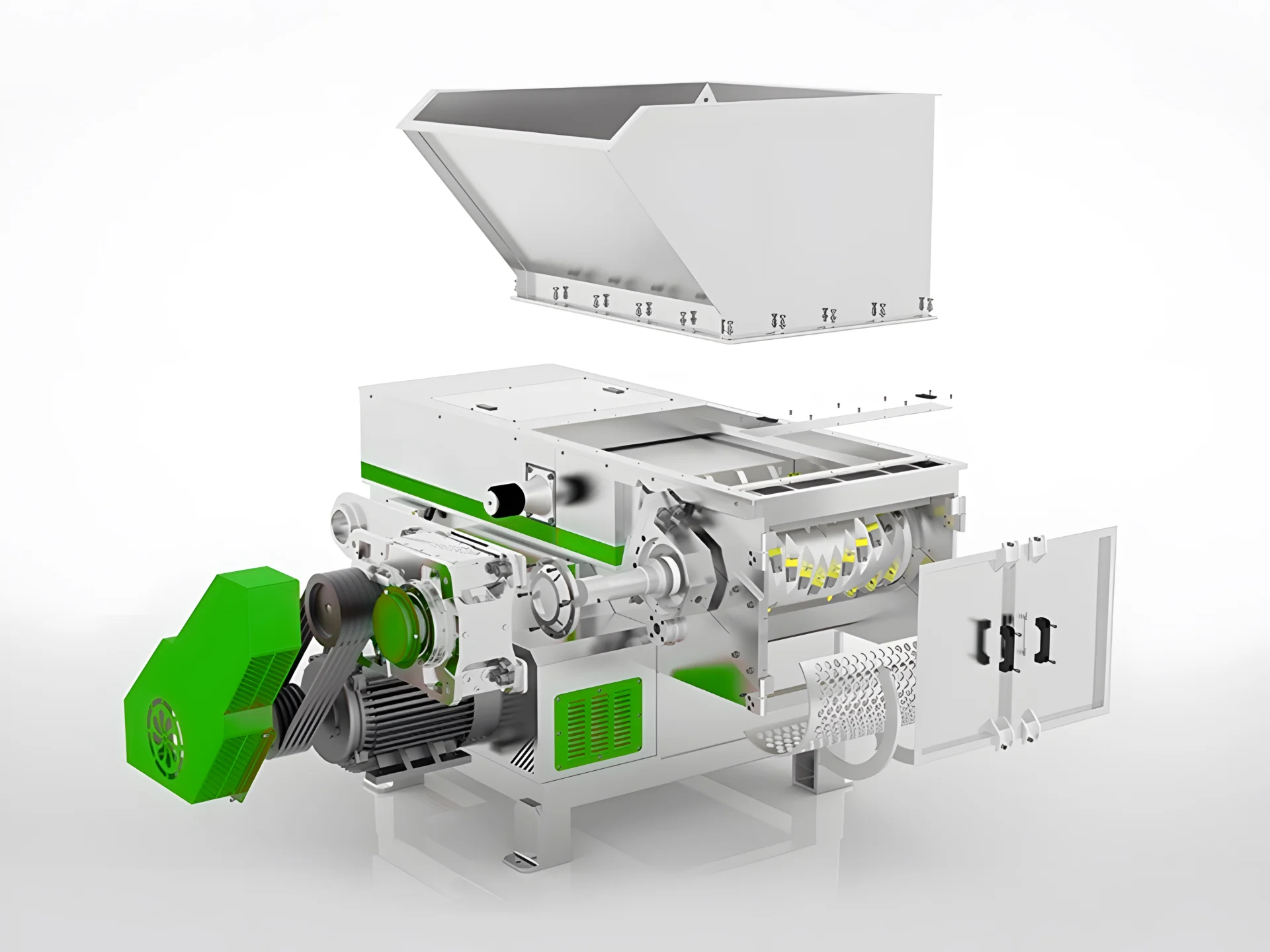

Optimized Rotor Designs

The design of the granulator rotor plays a crucial role in noise generation. Innovative rotor designs, such as helical and staggered blade configurations, help reduce noise by minimizing turbulence and vibrations. These optimized designs not only contribute to noise reduction but also improve the overall performance and efficiency of the granulator.

Energy Efficiency Improvements

Another area where plastic granulators are seeing significant advancements is energy efficiency. As the recycling industry strives to reduce its environmental impact, manufacturers are developing granulators that consume less energy without compromising performance.

High-Efficiency Motors

The integration of high-efficiency motors is one of the key innovations in energy-efficient granulators. These motors consume less electricity while delivering the same or even better performance compared to traditional motors. By reducing energy consumption, recycling facilities can lower their operating costs and minimize their carbon footprint.

Optimized Cutting Chamber Designs

The design of the cutting chamber also plays a vital role in energy efficiency. Innovative designs, such as optimized blade angles and cutting geometries, enable granulators to process plastic waste more efficiently. These improvements reduce the amount of energy required to achieve the desired granule size, resulting in significant energy savings.

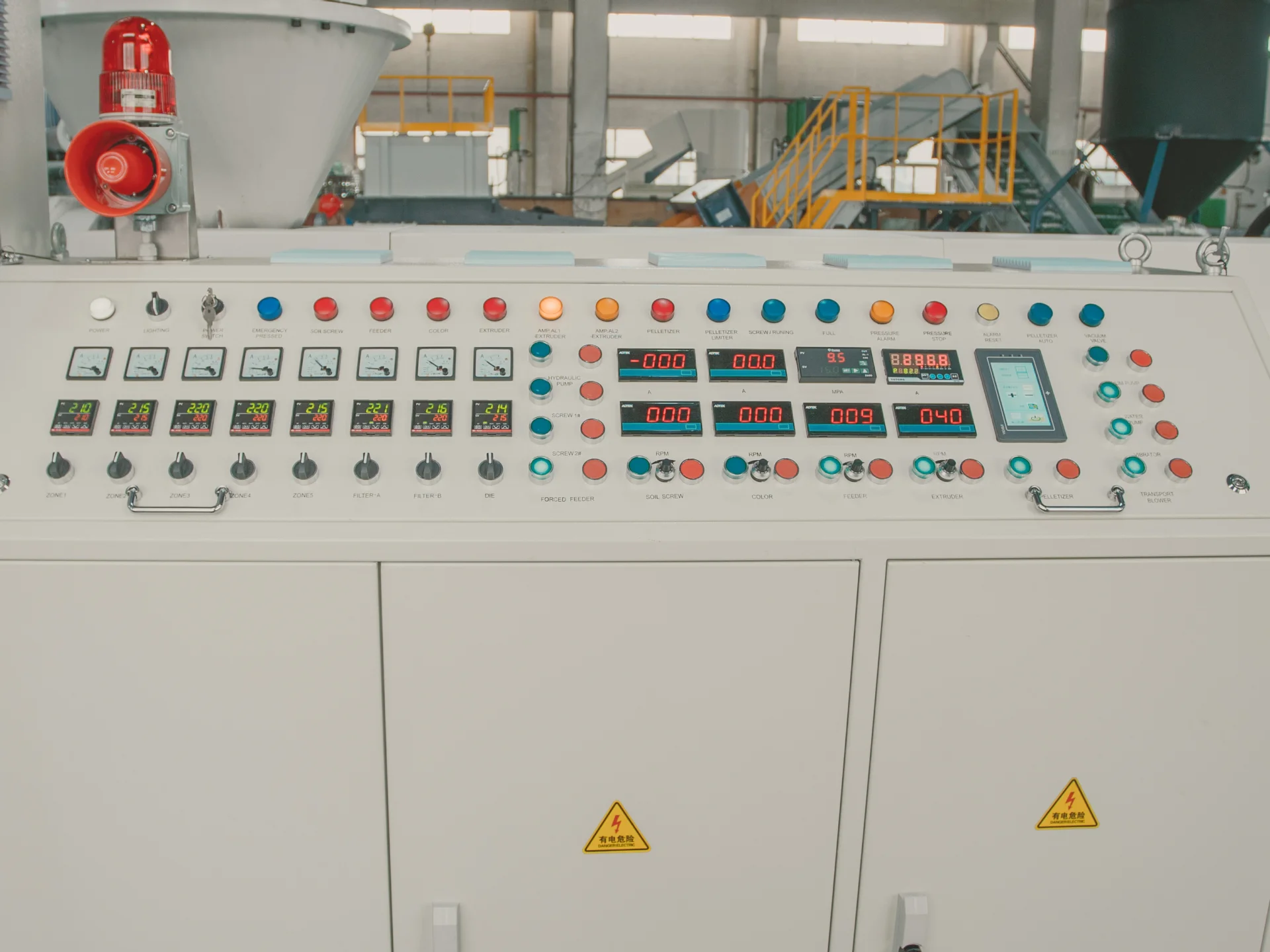

Smart Monitoring Systems

The integration of smart monitoring systems is another game-changing innovation in plastic granulators. These systems utilize sensors, data analytics, and connectivity to provide real-time insights into the performance and health of the granulator.

Predictive Maintenance

Smart monitoring systems can detect potential issues before they lead to breakdowns or failures. By analyzing data from sensors that monitor vibration, temperature, and other parameters, these systems can predict when maintenance is required. This predictive maintenance approach minimizes downtime, extends the lifespan of the granulator, and reduces overall maintenance costs.

Remote Monitoring and Control

With the advent of Internet of Things (IoT) technology, plastic granulators can now be remotely monitored and controlled. Operators can access real-time data, adjust settings, and receive alerts from anywhere, enabling them to optimize the granulator's performance and respond quickly to any issues. This level of connectivity and control enhances the efficiency and flexibility of recycling operations.

The Impact of Granulator Innovations on the Recycling Industry

The innovations in plastični granulatori are having a profound impact on the recycling industry. By improving efficiency, reducing noise and energy consumption, and enabling predictive maintenance, these advancements are making the recycling process more sustainable and cost-effective.

Increased Recycling Capacity

With more efficient and reliable granulators, recycling facilities can process larger volumes of plastic waste in less time. This increased capacity helps keep pace with the growing demand for recycled plastic and contributes to the overall growth of the recycling industry.

Reduced Environmental Impact

The energy efficiency improvements and noise reduction technologies in modern granulators are significantly reducing the environmental impact of plastic recycling. By consuming less energy and minimizing noise pollution, these innovations are making the recycling process more sustainable and environmentally friendly.

Enhanced Profitability

The cost savings achieved through energy efficiency, predictive maintenance, and increased recycling capacity are boosting the profitability of recycling operations. As granulators become more efficient and reliable, recycling facilities can optimize their processes, reduce operating costs, and improve their bottom line.

Zaključak

The innovations in plastic granulators are revolutionizing the recycling industry by addressing key challenges and improving the efficiency, sustainability, and profitability of plastic recycling. From noise reduction technologies and energy-efficient designs to smart monitoring systems, these advancements are transforming the way we process and recycle plastic waste. As the demand for recycled plastic continues to grow, the adoption of innovative granulatori will be crucial in building a more sustainable future.

Često postavljana pitanja (FAQ)

- What are the benefits of noise reduction technologies in plastic granulators?

Noise reduction technologies, such as soundproofing materials and optimized rotor designs, help create a quieter working environment, reduce noise pollution, and improve worker comfort and safety. - How do energy-efficient granulators reduce operating costs?

Energy-efficient granulators, equipped with high-efficiency motors and optimized cutting chamber designs, consume less electricity while maintaining high performance. This reduction in energy consumption leads to lower operating costs for recycling facilities. - What is predictive maintenance, and how does it benefit recycling operations?

Predictive maintenance involves using smart monitoring systems to detect potential issues before they lead to breakdowns or failures. By predicting when maintenance is required, recycling facilities can minimize downtime, extend the lifespan of their granulators, and reduce overall maintenance costs. - How do smart monitoring systems enhance the efficiency of plastic granulators?

Smart monitoring systems provide real-time data and insights into the performance and health of plastic granulators. This allows operators to optimize settings, respond quickly to issues, and make data-driven decisions to improve efficiency and productivity. - What role do innovative plastic granulators play in building a more sustainable future?

Innovative plastic granulators contribute to a more sustainable future by increasing recycling capacity, reducing energy consumption, and minimizing the environmental impact of plastic recycling. By making the recycling process more efficient and cost-effective, these advancements encourage the adoption of recycling practices and support the transition towards a circular economy.