Vijesti o recikliranju

The Nigerian plastic recycling market has seen significant growth over the years, driven by increasing awareness of environmental issues, government initiatives, and the economic potential of recycling. Here's a breakdown of its current status, processes, and implications:

Čvrsta plastika, koja obuhvaća materijale poput HDPE, LDPE, PET i PVC, sastavni je dio raznih industrijskih primjena, od potrošačke ambalaže do automobilskih dijelova. Recikliranje ovih materijala ne samo da pomaže u očuvanju resursa, već također značajno smanjuje otpad na odlagalištima i onečišćenje okoliša. Ovaj vodič ima za cilj istražiti opremu za recikliranje visokih performansi dizajniranu posebno za obradu krute plastike, pružajući uvid u to kako ti strojevi rade, zašto su neophodni i što treba uzeti u obzir pri odabiru prave opreme za vaš rad.

Maintaining PVC recycling machinery is vital for ensuring optimal performance, extending equipment longevity, and producing high-quality recycled products. Below is a detailed guide on best practices for maintaining PVC recycling machinery effectively.

Vinyl siding is widely used for its durability and low maintenance, but what happens when it reaches the end of its life? Recycling is a sustainable solution, and with the aid of vinyl recycling machines, the process becomes even more efficient. This guide will walk you through the essentials of vinyl siding recycling, including the role of specialized machines in making the process easier and more environmentally friendly.

PVC (polyvinyl chloride) is a widely used plastic in construction, packaging, and consumer goods. Recycling PVC can mitigate environmental harm and provide economic benefits, but it requires specialized equipment. Below is a structured cost-benefit analysis to help evaluate the investment.

What is Automotive Plastic Parts Recycling?

Automotive plastic parts recycling involves the process of reclaiming and reusing plastic components from vehicles. With the increasing emphasis on sustainability, recycling automotive plastics not only helps in managing waste but also in conserving resources.

Maximizing efficiency in PET (polyethylene terephthalate) recycling is essential for reducing environmental impact and enhancing operational productivity. To achieve this, consider the following strategies:

Rigid plastic recycling machines are pivotal in transforming waste plastics into valuable raw materials for manufacturing, contributing to both environmental sustainability and economic efficiency. Below is an in-depth look at the key components, functionalities, and benefits of these machines, along with guidance on selecting the right equipment for your business.

Rigid plastics, including items like containers, bottles, and durable goods, form a significant part of plastic waste. Recycling these materials not only conserves resources but also reduces environmental impact. Here's how you can select the best machine for recycling rigid plastics:

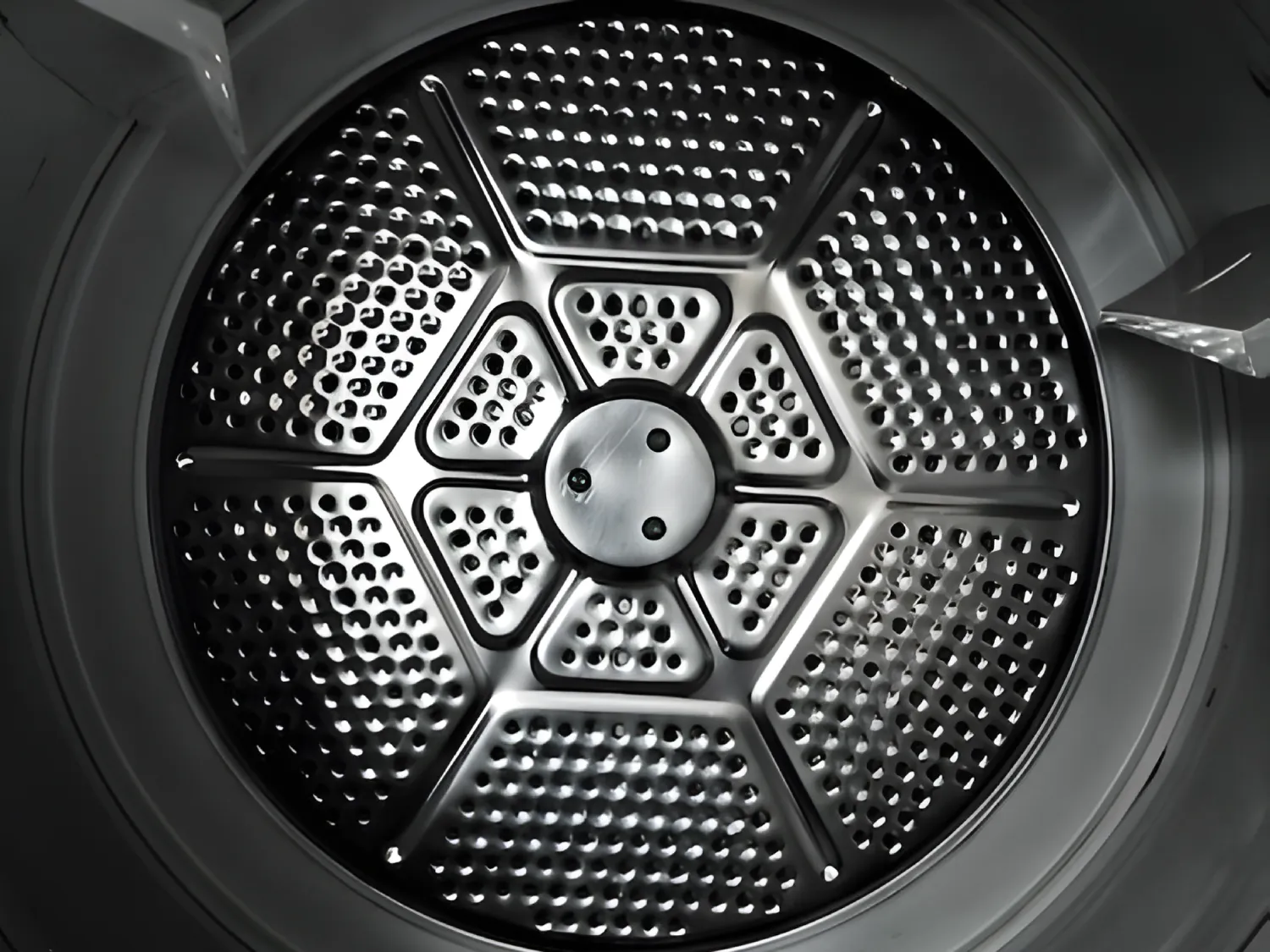

Centrifugalne sušače, koji se često koriste u industrijskim okruženjima za sušenje raznih materijala, rade na jednostavnom, ali učinkovitom principu. Ovi uređaji ključni su u procesima u kojima je potrebno brzo i učinkovito sušenje, kao što su tekstilna, kemijska i farmaceutska industrija. Ovdje ćemo istražiti kako ti strojevi funkcioniraju, zašto su učinkoviti i što ih čini nezamjenjivima u industrijskim primjenama.

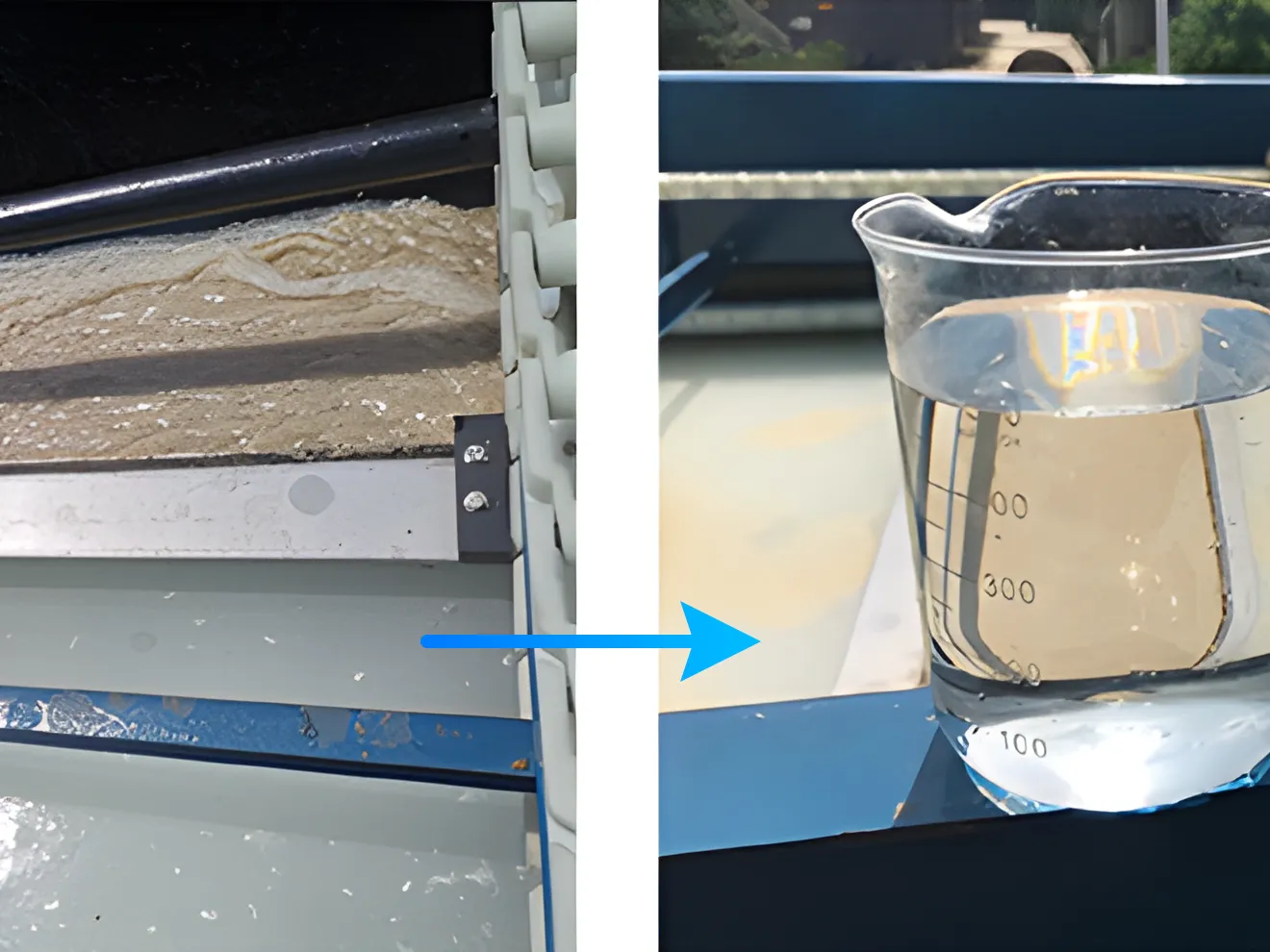

Wastewater from recikliranje plastike and washing is a major source of pollution in the plastic recycling and regeneration process, primarily originating from the cleaning, separation, and wet crushing of waste plastics. The concentration of pollutants in the wastewater is closely related to the characteristics of the raw waste plastics. For mixed, low-grade materials containing significant amounts of impurities such as paper and soil particles, the wastewater generation can reach up to 10 tons per ton of waste plastic. The wastewater produced during the cleaning and crushing stages contains high levels of organic matter and suspended solids, with chemical oxygen demand (COD) reaching up to 2000 mg/L and suspended solids (SS) up to 500 mg/L.

Introduction to PVC and Its Environmental Footprint

PVC, or Polyvinyl Chloride, is one of the most widely used plastics due to its versatility, durability, and cost-effectiveness. However, its lifecycle—from production to disposal—can have significant environmental implications. This article explores how recycling PVC can mitigate these impacts, focusing on reducing carbon footprints and managing plastic waste effectively.