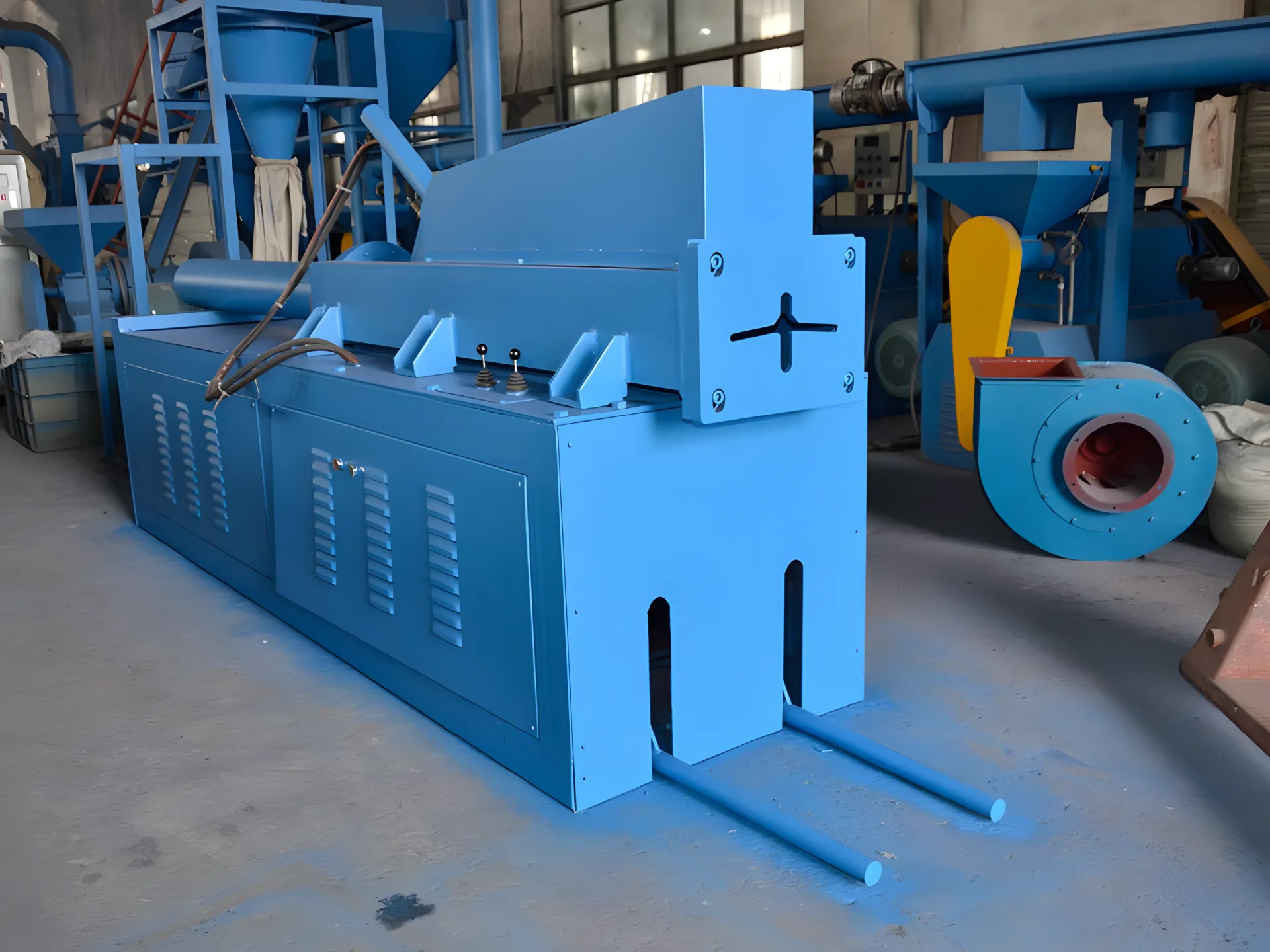

Stroj za skidanje rubova žice s jednom kukom neophodan je u recikliranju guma. Učinkovito uklanja čelične žice s bočnih stijenki gume prije rezanja i usitnjavanja. Ovaj je korak ključan za čišće krajnje proizvode i produljuje životni vijek naknadne opreme za obradu.

Struktura i komponente

Ovaj stroj se sastoji od nekoliko ključnih dijelova:

• Motor: Omogućuje potrebnu snagu za rad.

• Kuka i ploča s križnim rupama: Izrađen od posebno obrađenih materijala otpornih na habanje, koji osiguravaju izdržljivost i dugovječnost.

• Okvir tijela: Nudi strukturnu potporu i stabilnost tijekom rada.

• Cilindrična i hidraulička stanica: Koristite naprednu tehnologiju klipne pumpe, isporučujući visok tlak uz nisku buku, povećavajući stabilnost i životni vijek stroja.

• Poluga za upravljanje i kotačić za usmjeravanje: Omogućuje ručnu kontrolu nad procesima dizanja i povlačenja, osiguravajući preciznost i sigurnost.

Princip rada

Proces uklanjanja rubova počinje postavljanjem gume na platformu stroja. Kuka se zatim umetne u bočnu stijenku gume kako bi se zakačila za čeličnu žicu. Kroz ručni rad poluge, hidraulički sustav aktivira cilindar, generirajući znatnu silu da se žica perle potpuno izvuče. Ova metoda osigurava da je guma spremna za sljedeće operacije rezanja i usitnjavanja.

Prednosti

• Poboljšana učinkovitost: Opremljen uređajem za podizanje, stroj pojednostavljuje utovar guma, povećava brzinu obrade i smanjuje ručni rad.

• Kontrola preciznosti: Ručno upravljanje polugom omogućuje preciznu kontrolu tijekom faza podizanja i povlačenja, osiguravajući da se žica ruba ukloni bez nepotrebnog oštećenja gume.

• Izdržljivost: Upotreba materijala otpornih na habanje za kuku i ploču s poprečnim rupama, u kombinaciji s naprednom hidrauličkom tehnologijom, rezultira strojem dizajniranim za teške uvjete rada s produljenim vijekom trajanja.

Kinopredstava

Tehnički parametri

| Parametar | Model 900 | Model 1200 |

|---|---|---|

| Kapacitet (kom/h) | 20~40 | 20~40 |

| Rukovanje gumom (mm) | ≤Φ900 | ≤Φ1200 |

| Snaga motora (kw) | 5.5 | 11 |

| Radni tlak (Mpa) | 10 | 15 |

| Klipna udaljenost cilindra (mm) | 900 | 1300 |

| Težina (T) | 1 | 1.4 |