U industriji olovnih baterija, proizvodni proces počinje pretvaranjem sirovih olovnih ingota u olovne granule. Tradicionalno, olovo se prvenstveno topi za lijevanje ili rezanje u granule. Ove se granule zatim prerađuju u olovni prah pomoću strojeva za mlin s kuglicama.

Kako bismo pojednostavili ovaj proces, razvili smo automatsku proizvodnu opremu za hladno peletiranje olovnih ingota. Ova oprema revolucionira tradicionalnu metodu taljenja olova za lijevanje granula i omogućuje automatiziranu proizvodnju hladnih granula olova. Cjelokupnim radom upravlja PLC sustav. Ova inovacija rješava nekoliko problema povezanih s tradicionalnim procesom, kao što su visoko onečišćenje i potrošnja energije. Štoviše, nudi značajne prednosti, uključujući poboljšanu zaštitu okoliša, energetsku učinkovitost i povećanu učinkovitost proizvodnje, a sve to značajno koristi industriji olovnih baterija.

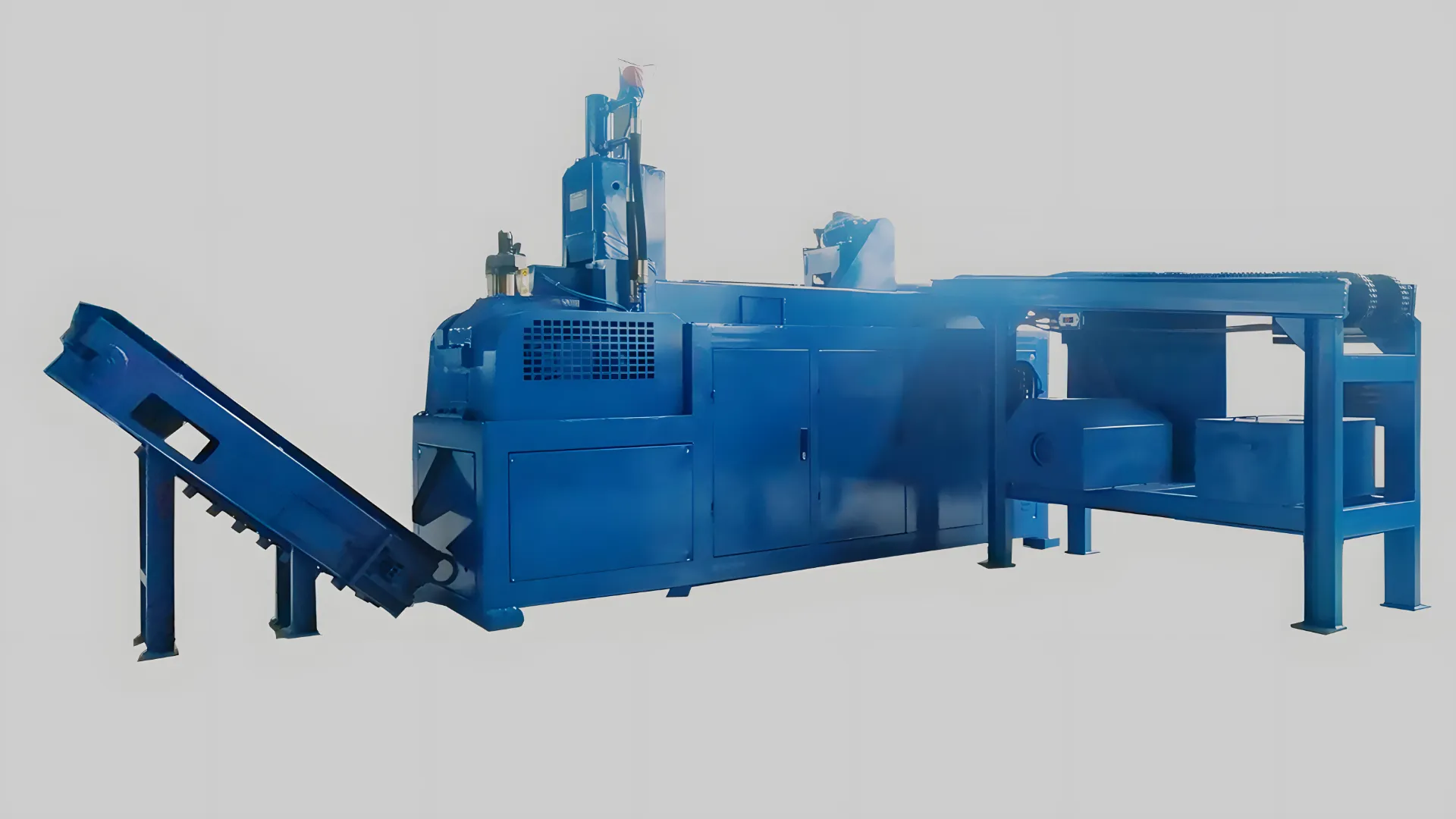

Predstaviti:

Ovaj stroj za hladno rezanje olovnih ingota je posebno dizajniran za rezanje olovnih ingota u olovne granule, s mehanizmom za prijenos olovnih ingota, mehanizmom za ekstruziju, mehanizmom za prijenos olovne trake, mehanizmom za dijeljenje trake, mehanizmom za rezanje granula i mehanizmom za prijenos olovnih granula. U početku, transportni mehanizam olovnih ingota transportira olovne ingote do mehanizma za istiskivanje, koji komprimira ingote više puta kako bi se oblikovale olovne trake. Ove trake se zatim transportiraju van pomoću mehanizma za transport vodeće trake i dalje transportiraju do mehanizma za rezanje granula pomoću mehanizma za dijeljenje traka. Mehanizam za rezanje granula reže olovne trake u granule, koje konačno izlaze putem mehanizma za transport olovnih granula. Ovaj dizajn omogućuje stroju za hladno rezanje obradu olovnih ingota u hladnom stanju, učinkovito izbjegavajući štetne olovne pare koje se mogu proizvesti tijekom procesa taljenja olovnih ingota.

Tehnički podaci:

1. Napon: 380 V, tri do četiri linije, 50 Hz.

2. Instalirana snaga: 28,8 kW/h.

3. Stvarna potrošnja energije: 15 kW/h ili manje.

4. Pojedinačni set opreme: Koristi 1 standardni olovni ingot (45 kg po ingotu). Prikladno za potrebe granulacije jednog 24T kugličnog mlina ili dva kuglična mlina od 14T.

5. Veličina granulacije: Od 25 x 25 x 17 mm do 20 mm.

6. Težina zrna: 75 do 100 g ± 15 g.

7. Kapacitet proizvodnje: 2,5 T/h do 2,75 T/h.

8. Primjenjivi tlak zraka: Ne manje od 0,4-0,7 MPa.

9. Prikladan pritisak vode: 0,2 MPa.

10. Temperatura vode: 10°C do 25°C.

11. Izvozna visina opreme za granulaciju: 350 m.

12. Hidraulično ulje za opremu: Hidraulično ulje protiv habanja marke Great Wall L-HM46.

13. Dimenzije opreme:

• Glavna jedinica: 3028 mm x 1040 mm x 2100 mm.

• Pomoćna jedinica: 2200 mm x 760 mm x 1450 mm.

• Olovni strugački transporter: 1450 mm x 350 mm x 1250 mm.

14. Ukupna težina stroja: Otprilike 4 T.