Recikliranje guma nije samo ekološka praksa, već i unosna poslovna prilika. U središtu recikliranja guma nalazi se granulator guma, snažan stroj dizajniran za pretvaranje otpadnih guma u manje granule za višekratnu upotrebu. Ali s toliko mnogo opcija na tržištu, odabir pravog stroja može biti zastrašujući. Ovaj sveobuhvatni vodič istražuje granulatore guma, uspoređujući modele, značajke i mogućnosti kako bi kupcima pomogli u donošenju informiranih odluka.

Što su granulatori guma i kako rade?

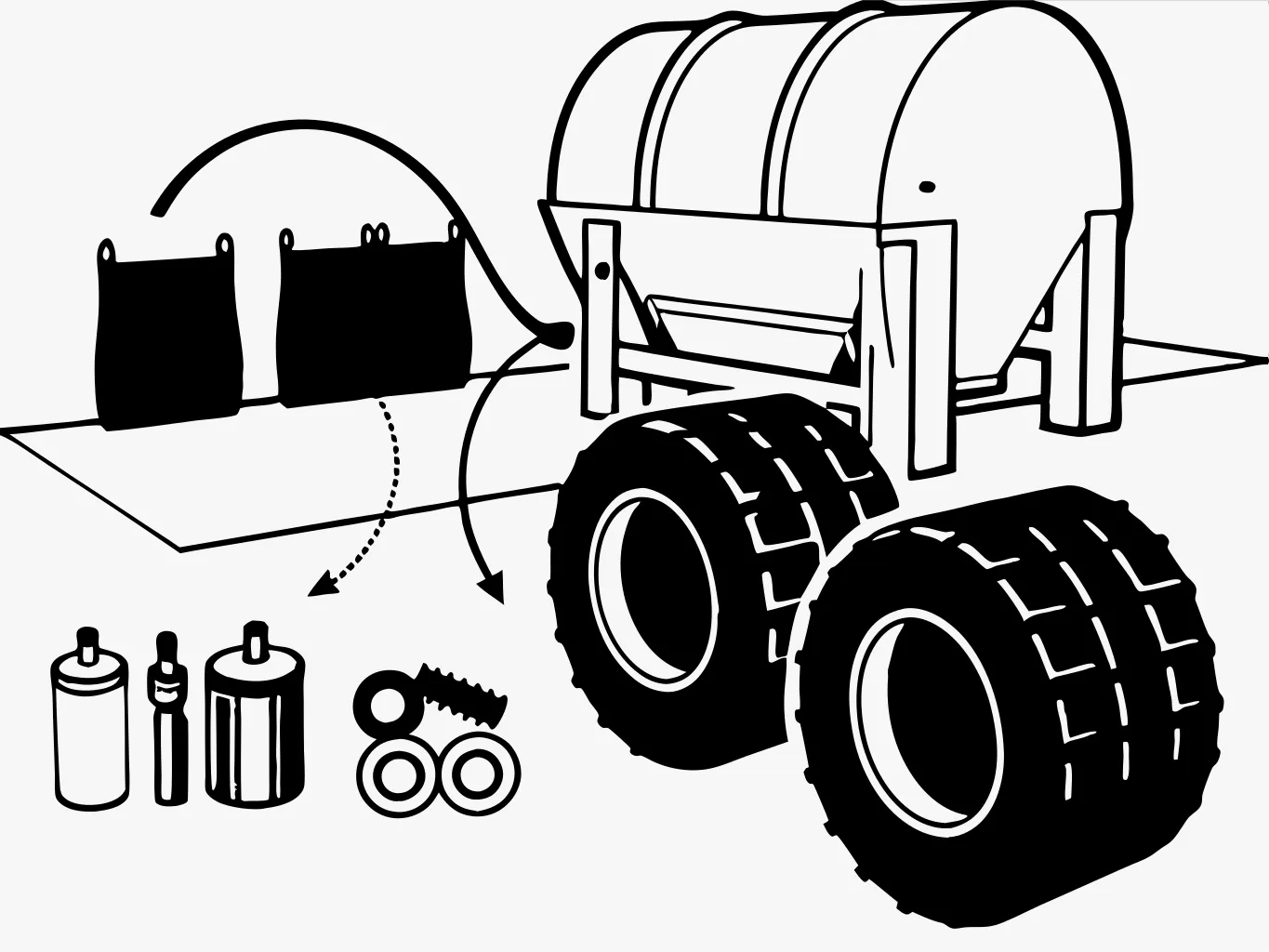

Granulatori guma specijalizirani su strojevi koji se koriste za usitnjavanje i preradu otpadnih guma u manje čestice, koje se često nazivaju gumenim granulama. Ove granule imaju širok raspon primjena, od izrade površina za igrališta do proizvodnje novih proizvoda od gume.

Kako rade granulatori guma?

Proces uključuje ubacivanje otpadnih guma u granulator, gdje ih robusne oštrice režu na manje komade. Ovisno o konfiguraciji stroja, granulatori mogu smanjiti materijal gume u:

- Gumene granule: Fine čestice koje se često koriste na gumiranom asfaltu ili sportskim terenima.

- Gumeni prah: Izuzetno fine čestice za industrijsku upotrebu.

- Odvajanje čelika i vlakana: Mnogi granulatori imaju sustave za uklanjanje čelika i vlakana iz guma, ostavljajući čistu gumu.

Učinkovitost granulatora ovisi o čimbenicima kao što su oštrina oštrice, snaga motora i vrsta guma koje se obrađuju.

Ključni čimbenici koje treba uzeti u obzir pri odabiru granulatora za gume

Odabir pravog granulatora za gume zahtijeva razumijevanje vaših specifičnih potreba i mogućnosti stroja. Evo što treba ocijeniti:

1. Zahtjevi za izlaznu veličinu

Različite industrije zahtijevaju različite veličine granula. Na primjer:

- Površine igrališta možda će trebati grube granule.

- Gumirani asfalt primjene često zahtijevaju fini gumeni prah.

Odaberite granulator koji odgovara željenoj izlaznoj veličini.

2. Kapacitet obrade

Strojevi se razlikuju po tome koliko guma mogu obraditi na sat. Operacije malih razmjera mogu biti dovoljne sa strojevima manjeg kapaciteta, dok industrijske postavke zahtijevaju modele visoke propusnosti.

3. Trajnost i održavanje oštrice

Noževi su najkritičnija komponenta granulatora. Tražiti:

- Oštrice od visokokvalitetnog čelika za dugovječnost.

- Strojevi sa sustavima za jednostavnu zamjenu oštrica kako bi se smanjio zastoj.

4. Energetska učinkovitost

Troškovi energije mogu se brzo zbrojiti. Odlučite se za modele s energetski učinkovitim motorima i sustavima kako biste održali niske operativne troškove.

5. Odvajanje čelika i vlakana

Ne obrađuju svi granulatori jednako uklanjanje čelika i vlakana. Napredni modeli uključuju magnetske separatore i mehanizme za izvlačenje vlakana za čišće rezultate.

6. Razmatranja proračuna

Cijene uvelike variraju. Usporedite troškove uzimajući u obzir:

- Početna kupoprodajna cijena.

- Dugoročni troškovi održavanja.

- Potencijalne uštede energije.

Vrhunski granulatori guma za različite potrebe

Istražimo neke popularne granulatore kako bismo vam pomogli u odluci.

1. RUMTOO Granulatori

Poznati po svojoj robusnoj izradi i preciznosti, Rumtoo granulatori su vodeći u industriji. Oni nude:

- Napredni sustavi noževa za produženi vijek trajanja oštrice.

- Veliki propusni kapaciteti.

- Učinkovito odvajanje čelika i vlakana.

Najbolje za: Industrijske operacije koje zahtijevaju obradu velikog kapaciteta.

2. ECO Green Equipment Granulatori

ECO Green nudi strojeve usmjerene na okoliš s izvrsnom energetskom učinkovitošću. Ključne značajke uključuju:

- Modularni dizajni za jednostavnu nadogradnju.

- Svestranost u izlazu veličine granula.

Najbolje za: Srednja poduzeća koja daju prioritet održivosti.

3. Saturn Granutech Systems

Saturn granulatori poznati su po svom dizajnu za teške uvjete rada. Ističu se u:

- Obrada guma za velike kamione i OTR (off-the-road).

- Proizvodnja dosljednih, visokokvalitetnih granula.

Najbolje za: Operacije obrade vangabaritnih guma.

4. Granulatori Eldan

Eldanovi strojevi fokusirani su na jednostavnost korištenja, a karakteriziraju ih:

- Jednostavne kontrole.

- Kompaktni otisci za manje objekte.

Najbolje za: Početne tvrtke ili postavke ograničenog prostora.

Primjena granulata za gume

Razumijevanje krajnje upotrebe granula za gume može voditi vaš odabir stroja. Evo kako se koristi reciklirani materijal za gume:

| Primjena | Potrebna veličina granula | Opis |

|---|---|---|

| Sportski tereni | 1-3 mm | Gumena ispuna za umjetnu travu. |

| Površine igrališta | 4-10 mm | Površine koje apsorbiraju udarce za sigurnost. |

| Mješavina asfaltne gume | Prah (<1 mm) | Povećava izdržljivost asfalta i smanjuje buku s ceste. |

| Industrijska lijevana roba | Varijabilna | Novi gumeni proizvodi kao što su prostirke ili brtve. |

Savjeti za održavanje vašeg granulatora guma

Pravilno održavanje osigurava da vaš granulator ostane učinkovit i izdržljiv. Slijedite ove najbolje prakse:

- Redovito provjeravajte oštrice: Provjerite tupost i po potrebi zamijenite.

- Podmažite pokretne dijelove: Spriječite trenje i habanje primjenom preporučenih maziva.

- Očistite stroj: Uklonite ostatke kako biste izbjegli začepljenje i održali učinkovitost.

- Pratite neobične zvukove: To često ukazuje na mehaničke probleme na koje je potrebno obratiti pozornost.

- Slijedite smjernice proizvođača: Uvijek se pridržavajte propisanih rasporeda održavanja.

Prednosti ulaganja u kvalitetan granulator guma

Visokokvalitetni granulatori nude brojne prednosti, uključujući:

- Povećana profitabilnost: Učinkovitim recikliranjem guma možete proizvesti vrijedne materijale za preprodaju.

- Utjecaj na okoliš: Recikliranje smanjuje otpad na odlagalištima i podržava kružno gospodarstvo.

- Operativna učinkovitost: Napredne značajke poput automatizirane separacije čelika štede vrijeme i rad.

FAQ

Koliki je životni vijek granulatora za gume?

Uz pravilno održavanje, visokokvalitetni granulator može trajati 10-15 godina ili duže.

Mogu li granulatori guma obraditi sve vrste guma?

Većina granulatora može rukovati automobilskim i kamionskim gumama, ali za obradu OTR guma mogu biti potrebni specijalizirani strojevi.

Koliko košta granulator za gume?

Cijene se kreću od $50,000 do $500,000, ovisno o veličini, kapacitetu i značajkama.

Trebaju li granulatori guma posebnu instalaciju?

Mnogi industrijski modeli trebaju odgovarajuću potporu temelja i električne konfiguracije. Posavjetujte se s proizvođačem.

Koliko energije troši granulator za gume?

Potrošnja energije ovisi o modelu. Odlučite se za energetski učinkovit dizajn kako biste smanjili troškove.

Koje sigurnosne mjere trebam slijediti?

Uvijek nosite zaštitnu opremu, slijedite operativne smjernice i osigurajte da funkcije zaustavljanja u nuždi rade.

Zaključak

Granulatori guma okosnica su svake uspješne operacije recikliranja guma. Odabir pravog stroja uključuje balansiranje čimbenika poput veličine izlaza, kapaciteta i proračuna. Bilo da se bavite malim recikliranjem ili velikim industrijskim prerađivačem, pravi granulator može povećati učinkovitost, smanjiti otpad i povećati profit. Odvojite vrijeme za procjenu svojih potreba i usporedite vrhunske modele kako biste obavili kupnju sa sigurnošću. S pravim strojem, pretvaranje otpadnih guma u vrijedne resurse postaje ostvariv i isplativ cilj. Recikliranje guma nije samo ekološka praksa, već i unosna poslovna prilika. U središtu recikliranja guma nalazi se granulator guma, snažan stroj dizajniran za pretvaranje otpadnih guma u manje granule za višekratnu upotrebu. Ali s toliko mnogo opcija na tržištu, odabir pravog stroja može biti zastrašujući. Ovaj sveobuhvatni vodič istražuje granulatore guma, uspoređujući modele, značajke i mogućnosti kako bi kupcima pomogli u donošenju informiranih odluka.