Vijesti o recikliranju

kategorije Vijesti o recikliranju

Objavljeno na

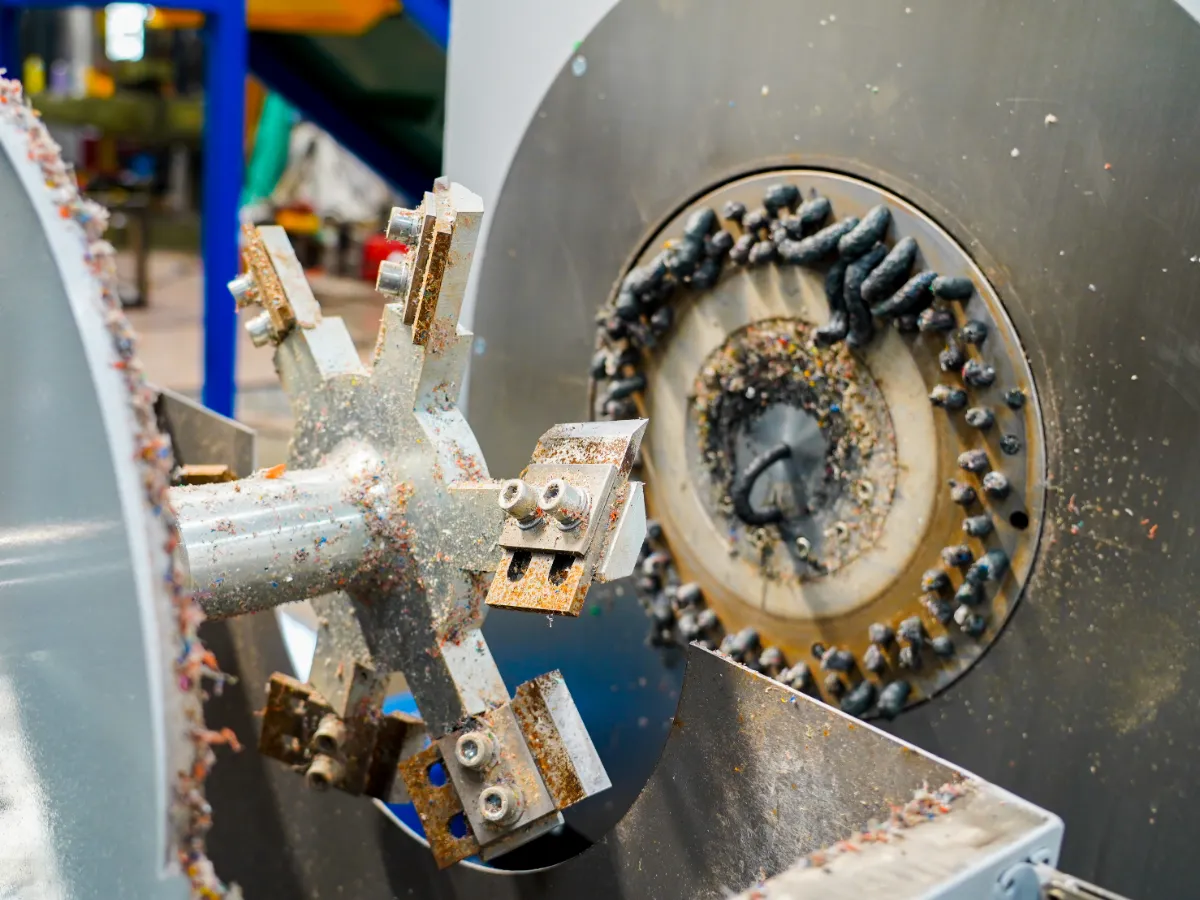

Istražite princip rada strojeva za uništavanje plastike i njihov utjecaj na napore recikliranja. Shvatite kako usitnjavanje glomazni plastični otpad pretvara u materijal koji se može reciklirati, pridonoseći održivosti okoliša.

kategorije Vijesti o recikliranju

Objavljeno na

Saznajte kako ovi strojevi pretvaraju plastični otpad u granule za višekratnu upotrebu, olakšavajući održive prakse i doprinoseći kružnom gospodarstvu.

kategorije Vijesti o recikliranju

Objavljeno na

Istražite najnovije inovacije u tehnologijama recikliranja PET boca i kako one transformiraju industriju. Od poboljšanih procesa prethodne obrade do kemijskog recikliranja, saznajte kako ova poboljšanja utiru put prema održivoj budućnosti.

kategorije Vijesti o recikliranju

Objavljeno na

Otkrijte ključne čimbenike koji utječu na cijene strojeva za recikliranje plastike i kako informirano ulagati u održivu tehnologiju. Ovaj vodič nudi uvid u odabir pravog stroja za vaše potrebe recikliranja.

kategorije Vijesti o recikliranju

Objavljeno na

Istražite financijske i ekološke prednosti ulaganja u strojeve za recikliranje plastike. Ovaj članak nudi duboki zaron u analizu troškova i koristi, ističući kako cijena stroja za recikliranje plastike utječe na ukupne napore u pogledu održivosti.

kategorije Vijesti o recikliranju

Objavljeno na

Otkrijte kako odabrati savršen stroj za recikliranje plastike za svoje potrebe balansirajući cijenu stroja za recikliranje plastike, kvalitetu i učinkovitost. Donesite informiranu odluku kako biste unaprijedili svoje napore u recikliranju.

kategorije Vijesti o recikliranju

Objavljeno na

Istražite najnovije inovacije u tehnologiji strojeva za recikliranje plastike, od pirolize do digitalnog vodenog žiga, i otkrijte kako ta poboljšanja transformiraju industriju recikliranja i utječu na cijene strojeva.

kategorije Vijesti o recikliranju

Objavljeno na

Istražite dinamiku koja utječe na cijene strojeva za recikliranje plastike, uključujući tehnološke inovacije, regulatorne politike i globalne tržišne trendove. Shvatite kako ti čimbenici konvergiraju u oblikovanju budućnosti industrije recikliranja.

kategorije Vijesti o recikliranju

Objavljeno na

Otkrijte kako ulaganje u strojeve za recikliranje plastike može poboljšati učinkovitost, održivost i profitabilnost vašeg poslovanja. Učite iz uspješnih studija slučaja u raznim industrijama.

kategorije Vijesti o recikliranju

Objavljeno na

Saznajte više o inicijativama i partnerstvima čiji je cilj preobraziti nacionalnu plastičnu dilemu u održivi poslovni model, potičući kružno gospodarstvo.

kategorije Vijesti o recikliranju

Objavljeno na

Otkrijte kako Caglia Environmental, uz pomoć The Recycling Partnership i EverestLabs, revolucionira recikliranje PET-a putem umjetne inteligencije i robotike. Saznajte više o njihovom inovativnom pristupu održivosti okoliša

kategorije Vijesti o recikliranju

Objavljeno na

Istražite kako umjetna inteligencija revolucionira industriju recikliranja, povećavajući učinkovitost procesa poput sortiranja i globalne trgovine reciklirajućim materijalima. Otkrijte transformativni učinak strojeva za recikliranje plastike koje pokreće umjetna inteligencija u poticanju održivosti.