Vijesti o recikliranju

Rabljena oprema za recikliranje može biti isplativo rješenje za tvrtke koje žele poboljšati svoje operacije recikliranja bez prekomjernog trošenja. Bez obzira vodite li mali centar za recikliranje ili trebate dodatne strojeve za industrijske svrhe, kupnja rabljene opreme nudi i financijske i ekološke prednosti. Evo praktičnog vodiča o tome što uzeti u obzir kada tražite rabljenu opremu za recikliranje za prodaju u blizini.

1. Prednosti kupnje rabljene opreme za recikliranje

Ušteda troškova: Rabljena oprema košta znatno manje od novih strojeva, što vam omogućuje da svoj proračun rasporedite negdje drugdje. Ovo je osobito važno za mala poduzeća ili startupe.

Održivost: Kupnjom rabljenog pridonosite kružnom gospodarstvu i smanjujete potražnju za novom proizvodnjom.

Trenutačna dostupnost: Rabljena oprema često je spremna za preuzimanje ili isporuku, što skraćuje vrijeme isporuke u usporedbi s naručivanjem novih jedinica.

2. Što tražiti pri kupnji rabljene opreme za recikliranje

Stanje opreme: Pregledajte ima li strojeva istrošenosti, hrđe ili bilo kakvih vidljivih oštećenja. Ako je moguće, zatražite evidenciju o održavanju kako biste provjerili njegovu radnu povijest.

Kompatibilnost: Osigurajte da oprema odgovara zahtjevima vašeg objekta i da se neprimjetno integrira u vaše postojeće procese.

Testiranje funkcionalnosti: Prije kupnje testirajte opremu kako biste potvrdili da radi prema očekivanjima. Mnogi će prodavači ponuditi demonstraciju.

Reputacija marke: Odlučite se za poznate marke s poviješću izdržljivosti i pouzdanosti. To osigurava da možete lakše pronaći rezervne dijelove i podršku ako je potrebno.

Reputacija prodavača: Kupujte iz pouzdanih izvora. To uključuje certificirane trgovce, aukcije ili renomirane objekte za recikliranje koji nude višak opreme.

3. Gdje u blizini pronaći rabljenu opremu za recikliranje

Lokalni reciklažni centri: Obratite se tvrtkama za recikliranje u vašem području. Mnogi nadograđuju svoje strojeve i prodaju svoje starije modele.

Mrežna tržišta: Provjerite web stranice specijalizirane za prodaju industrijske opreme, kao što su Machinio, Recycler's World ili eBay for Business. Filtrirajte rezultate prema svojoj lokaciji kako biste pronašli opremu u blizini.

Trgovci opremom: Mnogi trgovci nude i nove i rabljene strojeve za recikliranje. Oni često daju jamstva ili usluge nakon prodaje.

Aukcije: Aukcije industrijske opreme izvrsne su za pronalaženje dobro održavanih rabljenih strojeva po konkurentnim cijenama. Potražite aukcije na mreži i osobne dražbe u svom području.

Umrežavanje: Obratite se lokalnim industrijskim grupama, trgovačkim udruženjima ili forumima na kojima stručnjaci za recikliranje dijele informacije o prodaji opreme.

4. Tipovi opreme za recikliranje koji su obično dostupni

Ovisno o vašim potrebama, ovdje su neki uobičajeni strojevi za recikliranje:

• balirke: Komprimirajte materijale za recikliranje poput kartona i plastike u kompaktne bale.

• Sjeckalice i drobilice: Obradite predmete kao što su staklo, drvo i plastika.

• Transportni sustavi: Učinkovito transportirajte materijale kroz svoj objekt.

• Strojevi za sortiranje: Odvojite reciklirajuće materijale prema vrsti materijala ili veličini.

• Granulatori: Rastavite plastiku na manje čestice za višekratnu upotrebu.

5. Zašto raditi s trgovcem od povjerenja

Kupnja od provjerenog trgovca osigurava da ćete dobiti pouzdanu opremu s točnim opisima. Mnogi trgovci pregledavaju, obnavljaju i testiraju strojeve prije prodaje. Također mogu ponuditi jamstva ili planove tekućeg održavanja. Da biste se povezali s uglednim prodavateljem, razmislite o tome da se obratite putem pouzdanog izvora. Na primjer, možete kontaktirajte Rumtoo Machinery da se raspitate o rabljenoj opremi za recikliranje za prodaju i saznate više o njihovoj ponudi.

6. Posljednji savjeti za kupnju rabljene opreme za recikliranje

• Dogovaranje cijene: Cijene rabljene opreme često su po dogovoru. Nemojte se ustručavati tražiti popuste ili dodanu vrijednost kao što je besplatna dostava.

• Pregledajte dokumentaciju: Provjerite da oprema nije ukradena ili opterećena založnim pravima.

• Plan prijevoza: Dogovorite logistiku za premještanje velikih strojeva na vaše mjesto.

Slijedeći ove korake, možete pronaći visokokvalitetnu rabljenu opremu za recikliranje koja zadovoljava vaše operativne potrebe, a pritom ostaje unutar proračuna.

Što je granulator otpadnih guma?

A otpadna guma granulator je specijalizirani industrijski stroj dizajniran za recikliranje otpadnih guma razbijanjem na manje komade za višekratnu upotrebu poznate kao gumene granule. Ove granule, koje su obično veličine od 1 mm do 20 mm, mogu se koristiti u raznim industrijama. Granulator je ključni dio procesa recikliranja guma, pomaže pretvoriti krupni otpad u vrijedne resurse koji se mogu ponovno koristiti u različitim primjenama.

Globalni izazov plastičnog otpada iziskivao je inovativna rješenja u tehnologiji recikliranja. Jedan od najrevolucionarnijih napredaka je integracija umjetne inteligencije (AI) u razvrstavanje i obradu plastike. AI tehnologije transformiraju industriju recikliranja povećavajući učinkovitost, točnost i ukupnu kvalitetu recikliranih materijala.

Industrije diljem svijeta – od petrokemije do farmaceutske – oslanjaju se na dodavače za kontrolu protoka rasutih materijala u svojim procesima. Međutim, ponašanje suhih rasutih tvari značajno varira ovisno o njihovim kemijskim i fizičkim svojstvima, što rukovanje materijalom čini složenim izazovom. Ovaj vodič istražuje kako razumijevanje karakteristika materijala i odabir prave tehnologije hranjenja može poboljšati učinkovitost procesa i kvalitetu proizvoda.

Ukupna vrijednost isporuke primarnih strojeva za plastiku u Sjevernoj Americi dosegnula je procijenjenih $319,0 milijuna u trećem tromjesečju 2024., označavajući 41.9% porast u odnosu na prethodni kvartal.

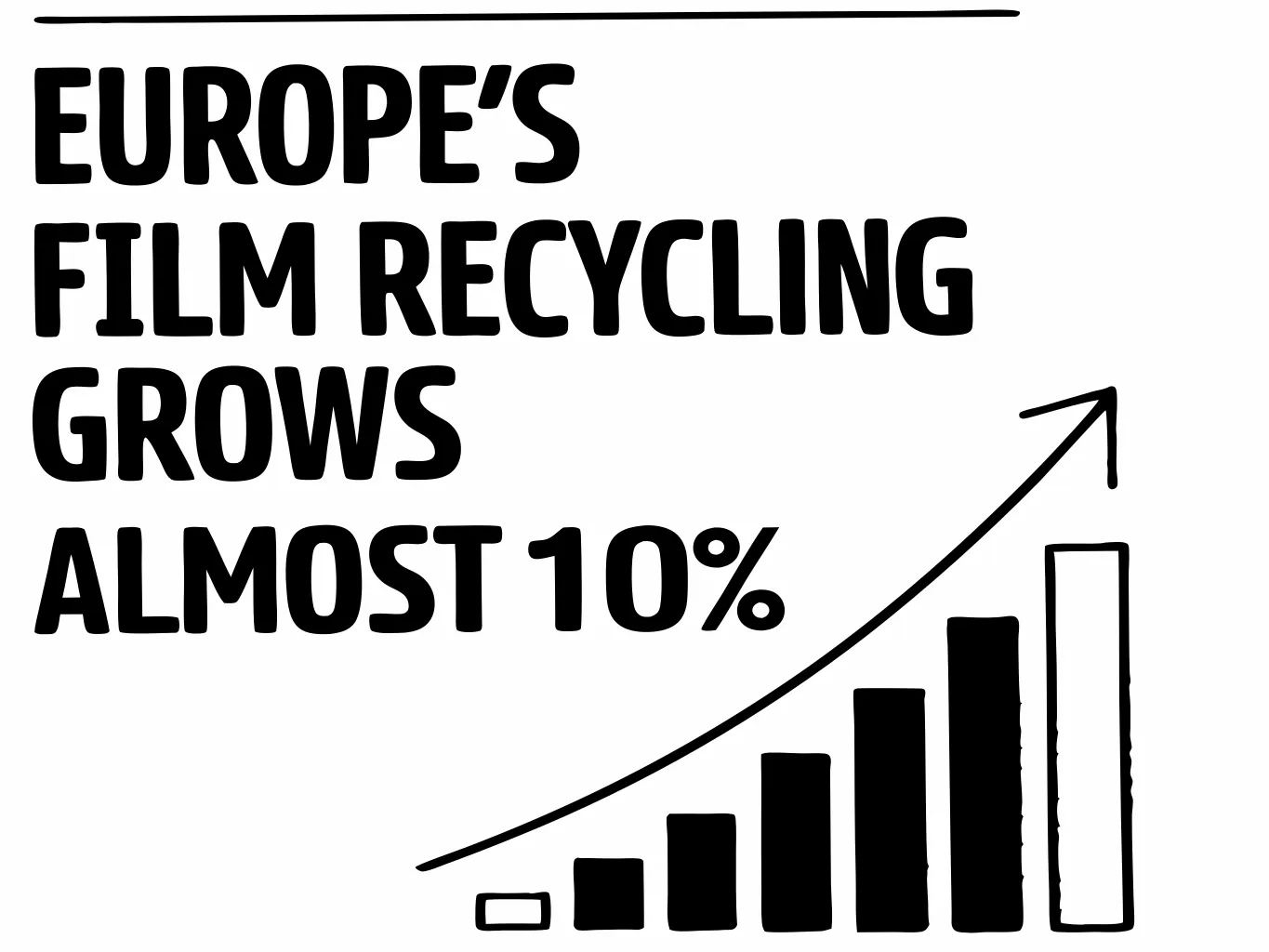

Unatoč značajnim poremećajima u gospodarenju otpadom zbog pandemije COVID-19, europski kapacitet recikliranja fleksibilne folije porastao je za gotovo 10% u 2020. Prema Plastics Recyclers Europe, ovaj rast naglašava vodeću ulogu regije u mehaničkom recikliranju folije i njenu predanost unaprjeđenju kružnog gospodarstva.

Nigerijsko tržište recikliranja plastike bilježi značajan rast tijekom godina, potaknuto povećanjem svijesti o problemima zaštite okoliša, vladinim inicijativama i ekonomskim potencijalom recikliranja. Evo raščlambe njegovog trenutnog statusa, procesa i implikacija:

Čvrsta plastika, koja obuhvaća materijale poput HDPE, LDPE, PET i PVC, sastavni je dio raznih industrijskih primjena, od potrošačke ambalaže do automobilskih dijelova. Recikliranje ovih materijala ne samo da pomaže u očuvanju resursa, već također značajno smanjuje otpad na odlagalištima i onečišćenje okoliša. Ovaj vodič ima za cilj istražiti opremu za recikliranje visokih performansi dizajniranu posebno za obradu krute plastike, pružajući uvid u to kako ti strojevi rade, zašto su neophodni i što treba uzeti u obzir pri odabiru prave opreme za vaš rad.

Održavanje strojeva za recikliranje PVC-a ključno je za osiguranje optimalnih performansi, produljenje vijeka trajanja opreme i proizvodnju visokokvalitetnih recikliranih proizvoda. U nastavku je detaljan vodič o najboljim praksama za učinkovito održavanje strojeva za recikliranje PVC-a.

Vinil sporedni kolosjek naširoko se koristi zbog svoje izdržljivosti i malog održavanja, ali što se događa kada dođe do kraja svog vijeka trajanja? Recikliranje je održivo rješenje, a uz pomoć strojevi za recikliranje vinila, proces postaje još učinkovitiji. Ovaj vodič će vas provesti kroz osnove recikliranja vinilnih obloga, uključujući ulogu specijaliziranih strojeva u olakšavanju procesa i ekološki prihvatljivijem.

PVC (polivinil klorid) je plastika koja se široko koristi u građevinarstvu, pakiranju i robi široke potrošnje. Recikliranjem PVC-a može se ublažiti šteta za okoliš i osigurati ekonomske koristi, ali zahtijeva specijaliziranu opremu. U nastavku je strukturirana analiza troškova i koristi koja će vam pomoći u procjeni ulaganja.

Što je recikliranje automobilskih plastičnih dijelova?

Recikliranje plastičnih dijelova za automobile uključuje proces vraćanja i ponovne upotrebe plastičnih dijelova iz vozila. Uz sve veći naglasak na održivost, recikliranje automobilske plastike ne samo da pomaže u upravljanju otpadom, već iu očuvanju resursa.