In today’s fast-evolving industrial landscape, efficient and dependable machinery is crucial for processing tough materials. The Hard Material Single Shaft Shredder emerges as a cutting-edge solution, engineered for high-efficiency shredding of even the most challenging substances. Below, we explore its standout features, versatile applications, and why it’s a game-changer for modern industries.

Key Features

1. Dynamic Shredding Chamber: Unlike traditional shredders, the entire shredding chamber moves dynamically, eliminating feeding bottlenecks and boosting efficiency. Its innovative hopper design adjusts automatically, ensuring seamless operation and stability without jams.

2. Robust Shaft Construction: Forged from a single block of high-grade iron and precision-machined, the shredder’s shaft is virtually unbreakable. This durable core thrives under the demands of heavy-duty shredding.

3. Secure Transmission Parts: Locked with couplings and iron pins, the transmission system safeguards the reducer, minimizes power loss, and enhances both safety and efficiency.

4. Enhanced Feeding Mechanism: A vertical hopper with a safety cover optimizes material intake and ensures operator safety, making it ideal for rigorous tasks.

5. Advanced Control System: Powered by a PLC program, the shredder offers intuitive controls—start, stop, reverse—and an automatic overload return to protect components and ensure long-term reliability.

Applications

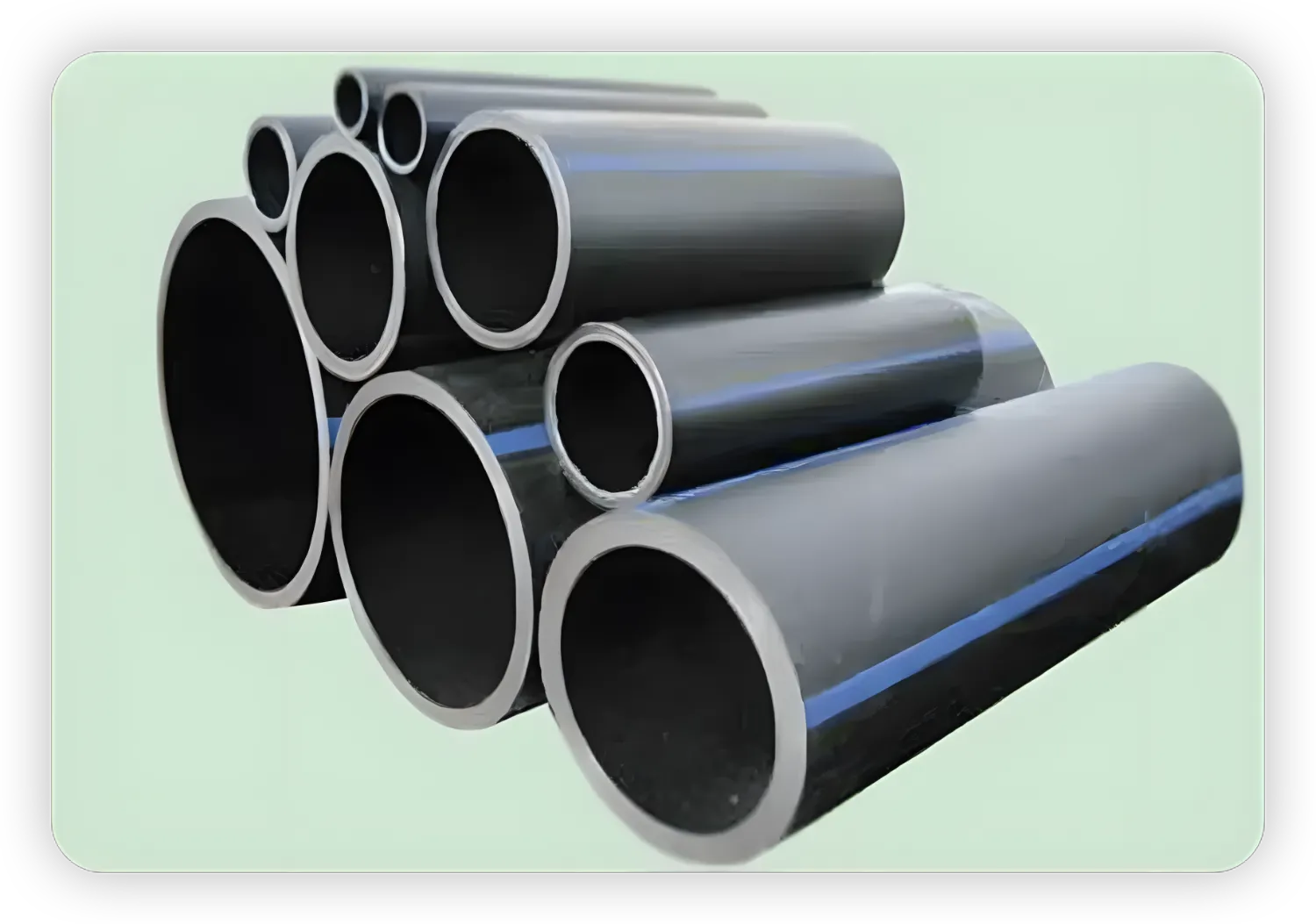

• Large Plastic and PVC Pipes: Effortlessly shreds large-diameter PE/PVC pipes for recycling or disposal.

• Heavy Plastics and Bulky Materials: Processes PP, PC, and ABS lump bullion into manageable sizes.

• Wooden Pallets: Breaks down pallets to support wood recycling efforts.

• Electronic Waste: Shreds wires, cables, and e-waste, aiding in material recovery.

• Tough Materials: Tackles waste metal, glass fiber, and carbon fiber with ease.

Watch the Shredder in Action

Technical Parameters

| Shredder Model | Shaft Diameter (mm) | Moving Knife Qty. (pcs) | Fixed Knife Qty. (pcs) | Max Capacity (kg/h) | Motor Power (KW) | Chamber Size (L x W) | Host Weight (kg) | Dimensions (L x W x H) |

|---|---|---|---|---|---|---|---|---|

| RTM-2455 | 275 | 24 | 1 | 400 | 22 | 780 x 550 | 3600 | 3250 * 1500 * 2350 |

| RTM-3063 | 275 | 30 | 1 | 500 | 30 | 780 x 670 | 4000 | 3250 * 1750 * 2350 |

| RTM-3980 | 275 | 39 | 1 | 700 | 37 | 1000 x 870 | 6000 | 4150 * 1900 * 2450 |

| RTM-48100 | 315 | 48 | 1 | 900 | 45 | 1200 x 1060 | 8000 | 4700 * 2550 * 2650 |

| RTM-57120 | 315 | 57 | 2 | 1200 | 55 | 1400 x 1260 | 9500 | 5350 * 2850 * 2760 |

| RTM-75160 | 350 | 75 | 2 | 1300 | 75 | 1800 x 1650 | 12000 | 5900 * 3050 * 2960 |

Why Choose Our Single Shaft Shredder?

Our Hard Material Single Shaft Shredder is more than just machinery—it’s a robust, all-in-one solution for industrial shredding needs. Combining innovative technology with a sturdy design, it delivers exceptional performance and reliability. From recycling to volume reduction, it effortlessly handles diverse materials, making it an essential asset for today’s industries.

For businesses aiming to streamline operations and minimize waste, this shredder is a transformative investment. With its advanced features and broad applicability, it’s equipped to tackle any heavy-duty shredding challenge with confidence.