Nel mondo odierno, la gestione dei rifiuti di plastica è diventata una sfida ambientale critica. Mentre le industrie cercano soluzioni sostenibili, i trituratori di plastica a doppio albero sono emersi come una tecnologia rivoluzionaria. Questo articolo esplora le caratteristiche, i vantaggi e le applicazioni di queste potenti macchine nel riciclaggio e nella riduzione dei rifiuti.

Cos'è un trituratore di plastica a doppio albero?

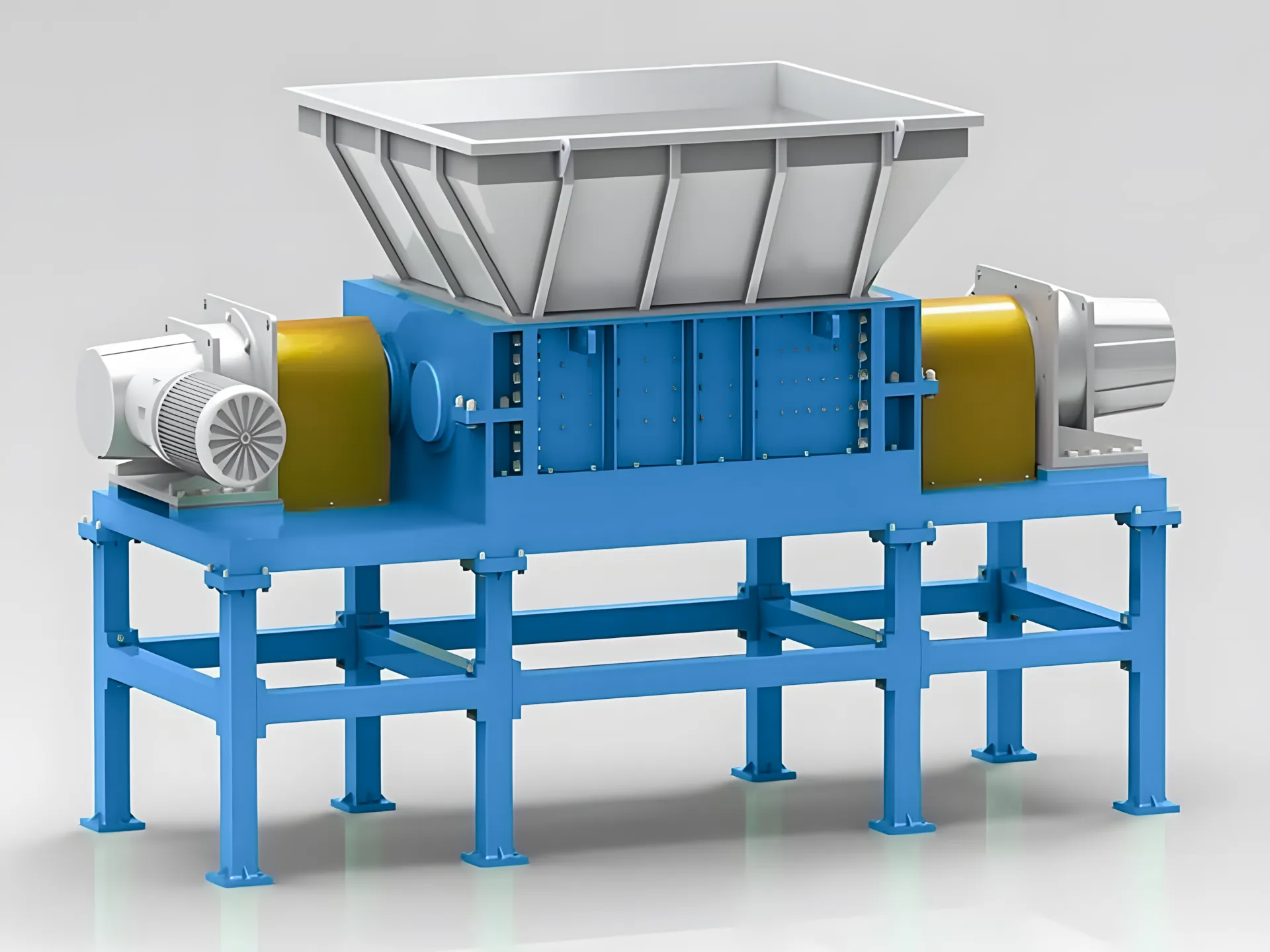

Un trituratore di plastica a doppio albero è una macchina industriale progettata per elaborare grandi volumi di rifiuti di plastica in modo efficiente. È dotato di due alberi controrotanti dotati di lame di taglio, in grado di gestire un'ampia gamma di materiali plastici, tra cui PVC, PET, HDPE e altro ancora.

Caratteristiche e vantaggi principali

- Triturazione ad alta efficienza: Il design a doppio albero garantisce una triturazione uniforme ed efficiente dei materiali.

- Versatilità: In grado di lavorare vari tipi di plastica e altri materiali.

- Costruzione robusta: Realizzato in acciaio altamente legato (42CrMo) per garantire durata e longevità.

- Caratteristiche di sicurezza: Dotato di pulsanti di arresto di emergenza, protezioni di sicurezza e protezione da sovraccarico.

- Sistema di inversione automatica: Inverte automaticamente la direzione del rotore in caso di sovraccarico o inceppamento.

- Pistone di spinta opzionale: Disponibile per la lavorazione di materiali cavi e di grandi dimensioni.

| Modello | Modello SJ400-800 | Modello SJ400-1200 | Modello SJ450-800 | Modello SJ450-1200 |

|---|---|---|---|---|

| Potenza del motore idraulico | 2×22kW | 2×30kW | 2×30kW | 2×45kW |

| Numero di lame | 16/26 | 24/40 | 16/26 | 24/40 |

| Capacità approssimativa | 1500 kg/ora | 2500 kg/ora | 3000kg/ora | 4000 kg/ora |

| Velocità di rotazione (giri/min) | 25/35 giri al minuto | 25/35 giri al minuto | 18/28 giri al minuto | 18/28 giri al minuto |

Trituratori monoalbero per gestire meglio pezzi solidi e spessi come scarti di plastica, guide, pallet e persino legno, rami e ossa.

I trituratori a doppio albero utilizzano lame di taglio per tagliare il materiale plastico e sono più adatti alla movimentazione di grandi volumi di materie plastiche cave e leggere, come pellicole in PE, tubi in PP, fusti in HDPE e persino pneumatici in gomma, parti di automobili e rifiuti elettronici.

Applicazioni in vari settori industriali

I trituratori a doppio albero trovano applicazione in molteplici settori:

- Riciclaggio della plastica: lavorazione dei rifiuti di plastica in piccole particelle per ulteriori trattamenti.

- Lavorazione del legno: frantumazione degli scarti di legno per la produzione di combustibile da biomassa.

- Gestione dei rifiuti elettronici: gestione dei dispositivi elettronici dismessi per l'estrazione di metalli preziosi.

- Riciclaggio generale: lavorazione di materiali diversi come pneumatici, rottami di acciaio e tessuti di scarto.

Benefici ambientali ed economici

- Riduzione dei rifiuti: Riduce significativamente il volume dei rifiuti plastici inviati in discarica.

- Conveniente: Riduce i costi di trasporto e le tariffe di discarica per le aziende.

- Efficienza energetica: Consuma meno energia rispetto ad altri metodi di triturazione.

- Economia circolare: Supporta gli sforzi di riciclaggio e promuove l'uso sostenibile delle risorse.

Trituratori monoalbero vs. bialbero

Sebbene entrambi i tipi abbiano i loro meriti, i trituratori a doppio albero eccellono in:

- Elaborazione di materiali più densi e duri

- Raggiungere tassi di produttività più elevati

- Produzione di output più uniforme

I trituratori monoalbero, invece, sono più adatti ai materiali più morbidi e sono generalmente più convenienti.

Conclusione

I trituratori di plastica a doppio albero rappresentano un significativo progresso nella tecnologia di gestione dei rifiuti. Investendo in queste macchine, le aziende possono migliorare le loro capacità di riciclaggio, ridurre l'impatto ambientale e potenzialmente risparmiare sui costi operativi. Mentre ci muoviamo verso un futuro più sostenibile, tecnologie come i trituratori a doppio albero svolgeranno un ruolo cruciale nella gestione efficace dei nostri rifiuti di plastica.

Garanzia

Tutte le macchine per il riciclaggio sono dotate di una garanzia limitata di 1 anno.

RICHIESTE

Per conoscere i prezzi e i tempi di consegna più recenti, inviaci un messaggio utilizzando il modulo sottostante.