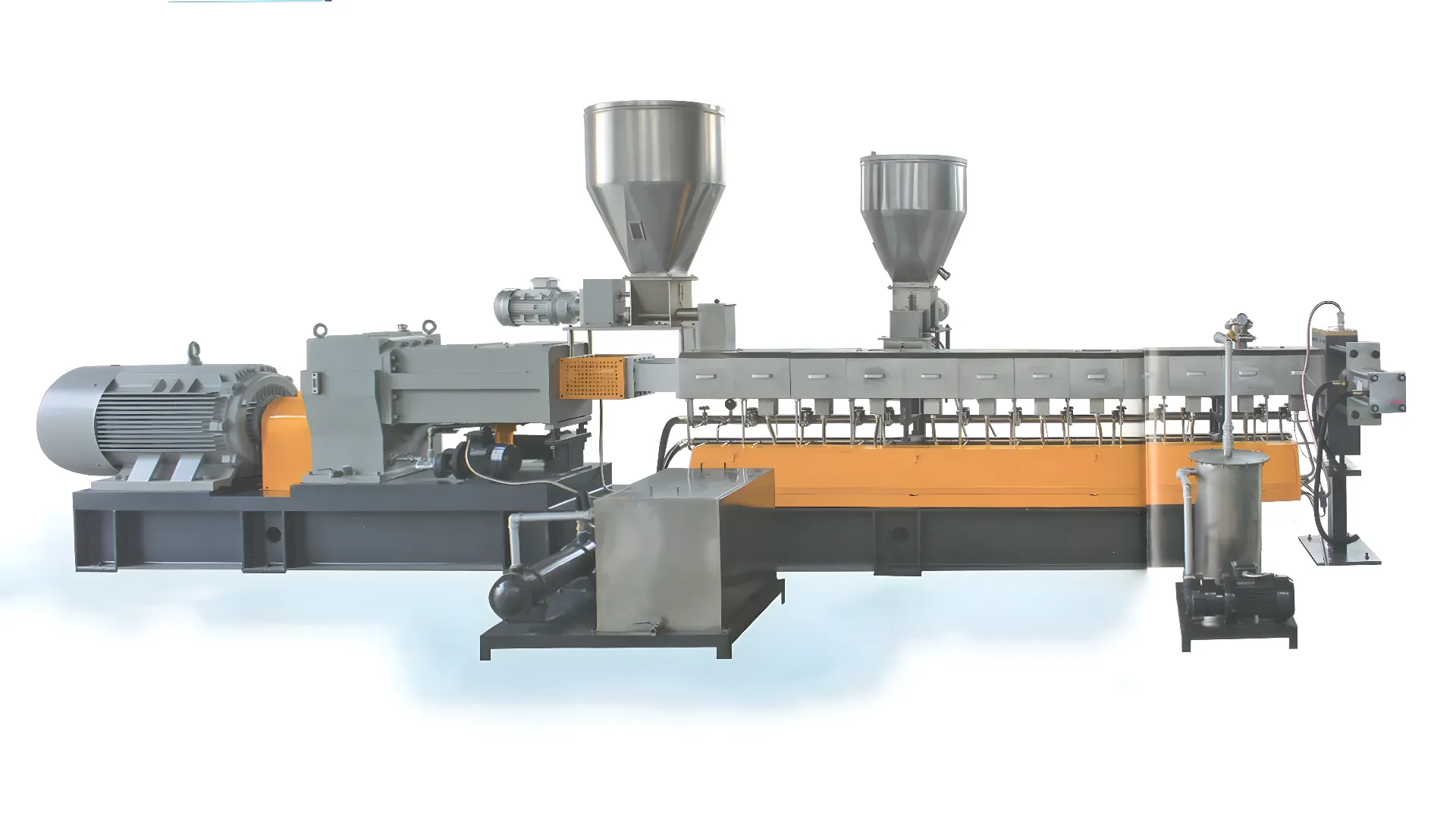

La Twin Screw Compounding Pelletizing Line rappresenta l'apice dell'innovazione nella lavorazione dei polimeri, offrendo versatilità e adattabilità senza pari per soddisfare le diverse esigenze delle industrie moderne. Che siate impegnati nella produzione di materie plastiche, nel riciclaggio o nella composizione di materiali, questo sistema all'avanguardia offre prestazioni eccezionali, su misura per le vostre esigenze.

Guarda una rapida panoramica della linea di pellettizzazione Twin Screw Compounding in azione.

Principi e caratteristiche della linea di pellettizzazione a doppia vite

Progettata con la modularità al centro, la Twin Screw Compounding Pelletizing Line offre configurazioni completamente personalizzabili per qualsiasi attività di lavorazione dei polimeri. Dal design della vite e dalla disposizione del cilindro ai rapporti lunghezza/diametro (L/D), sistemi di alimentazione, opzioni di sfiato, cambiafiltri, tecniche di taglio dei pellet e controlli di automazione avanzati, questo sistema fonde perfettamente multifunzionalità e personalizzazione di precisione.

Caratteristiche principali della linea di pellettizzazione

- Controllo avanzato della velocità del motore: Dotati di convertitori di frequenza digitali di alta qualità o regolatori di velocità CC per un funzionamento affidabile e ad alte prestazioni.

- Regolazione di precisione della temperatura: Dispone di regolatori di temperatura intelligenti digitali RKC o OMRON con ottimizzazione PID per una gestione precisa del calore.

- Sistema di raffreddamento affidabile: Incorpora elettrovalvole di alta qualità provenienti da marchi rinomati a livello mondiale, garantendo durata ed efficienza.

- Componenti elettrici di alta qualità: Utilizza componenti a bassa tensione Schneider, Siemens e Fuji alloggiati in armadi di controllo ventilati e di facile utilizzo per una facile manutenzione.

Elementi a vite per prestazioni ottimali: Gli elementi a vite coniugata completamente interbloccati garantiscono un'autopulizia e un'intercambiabilità superiori. Con oltre 20 anni di esperienza nella progettazione di viti e software avanzati, il sistema eccelle nel trasporto, nella fusione, nella miscelazione, nel taglio, nell'omogeneizzazione, nella devolatilizzazione e nell'estrusione, perfetto per diverse esigenze di compounding di polimeri.

Serie diverse per ogni esigenza: Scegli tra la serie A standard, la serie B ad alta velocità, la serie C ad alta coppia, la serie D ad alta velocità/alta coppia o le serie E e F all'avanguardia con capacità di coppia potenziate, per garantire la soluzione ideale per i tuoi obiettivi di produzione.

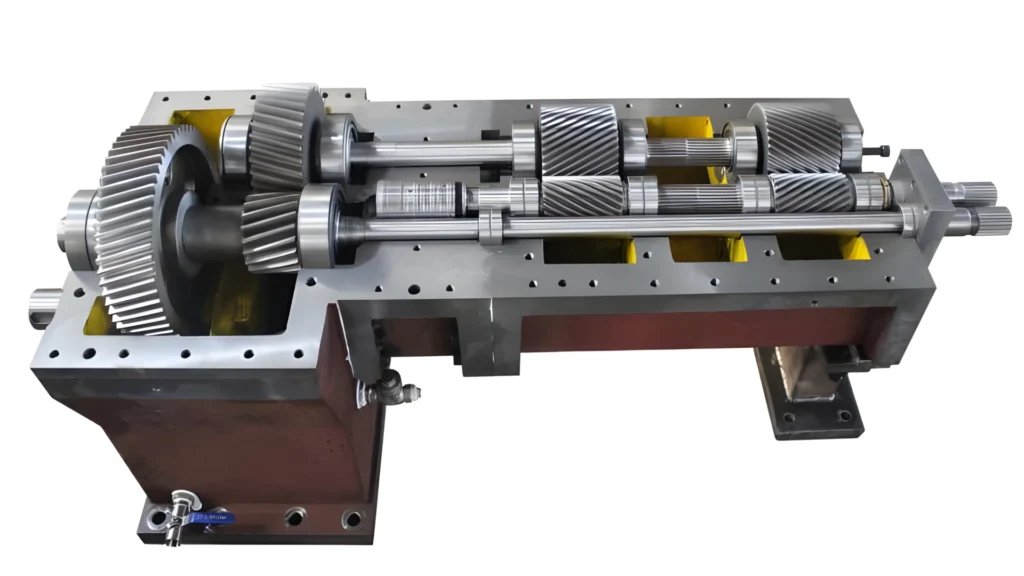

Dispositivo di trasmissione robusto: Un sistema di distribuzione della coppia di nuova concezione privilegia sicurezza, precisione e durata, con ingranaggi lavorati ad alta precisione e cuscinetti chiave importati per prestazioni affidabili anche in condizioni difficili.

Sistemi di alimentazione versatili: Supporta una gamma di opzioni di alimentazione del dosaggio (a vite singola, a vite doppia, a molla cava, a ingranamento e senza ingranamento) per gestire senza sforzo varie forme di materiali ed esigenze di lavorazione.

Materiali e costruzione durevoli: La canna bimetallica standard, realizzata con una base in acciaio 45# e un rivestimento in lega 8101, offre un'eccellente resistenza all'usura. Sono disponibili materiali e trattamenti specializzati per applicazioni corrosive o abrasive.

Design intuitivo: Grazie al basso livello di vibrazioni e rumore, il sistema supporta l'installazione senza fondamenta su qualsiasi superficie piana, semplificando l'installazione e riducendo i costi operativi.

Specifiche della linea di pellettizzazione a doppia vite

| Modello | Diametro (mm) | Rapporto L/D massimo | Velocità (giri/min) | Potenza (kW) | Produzione (kg/ora) |

|---|---|---|---|---|---|

| Modello RTM52C | 51.4 | 68 | 600 | 90 | 250–350 |

| RTM65C | 62.4 | 68 | 600 | 160 | 400–600 |

| Modello RTM75C | 71.4 | 68 | 600 | 250 | 700–1000 |

| Modello RTM85C | 81 | 68 | 600 | 280 | 800–1200 |

| Modello RTM95C | 93 | 68 | 600 | 450 | 1300–2000 |

| Modello RTM120C | 116 | 68 | 500 | 550 | 1500–2200 |

| Modello RTM135C | 133 | 68 | 500 | 1200 | 3500–5000 |

Riduttore ad alta precisione progettato per garantire durata ed efficienza.

Perché scegliere la nostra linea di pellettizzazione a doppia vite?

La nostra Twin Screw Compounding Pelletizing Line ridefinisce l'eccellenza nella tecnologia di lavorazione dei polimeri. Con la sua notevole adattabilità, l'ingegneria di precisione e il design intuitivo, rappresenta la soluzione definitiva per le aziende che si sforzano di primeggiare in un mercato competitivo.

Richiedi un preventivo oggi

Contattateci per richiedere un preventivo personalizzato per la vostra linea di pellettizzazione a doppia vite.