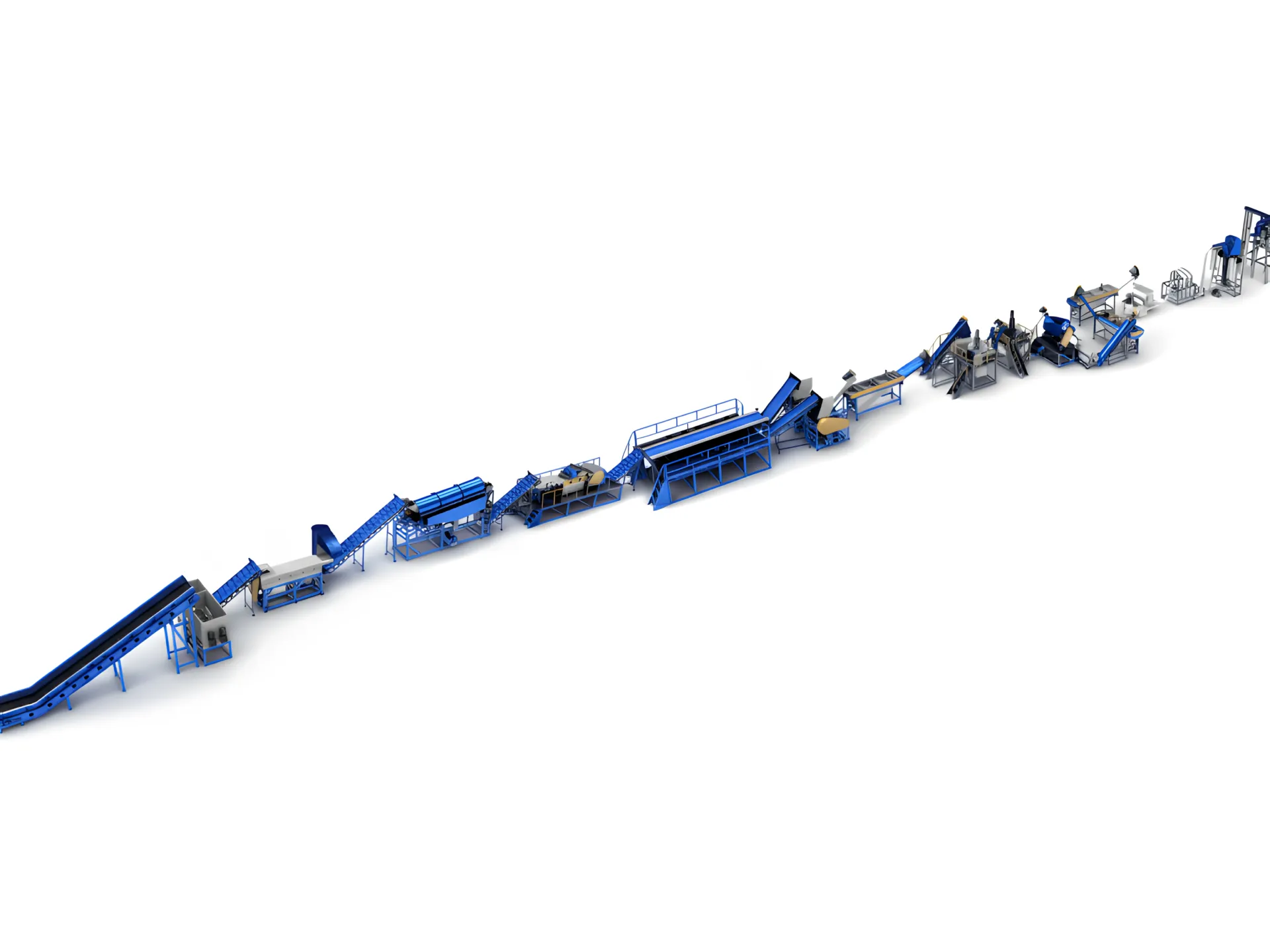

Linea di lavaggio e riciclaggio di plastica rigida in HDPE e PP

Trasformate i rifiuti ingombranti in HDPE/PP, come bottiglie, casse, fusti e tubi, in scaglie riciclate pulite e di alto valore. La nostra linea completamente automatizzata è progettata per garantire un'elevata produttività, una pulizia superiore e la massima efficienza.

Trasformare i rifiuti in una merce preziosa

Investire nella nostra linea di riciclo è una scelta intelligente per la tua azienda e per il pianeta. Crea una nuova fonte di reddito dai rifiuti plastici, raggiungendo al contempo i tuoi obiettivi di sostenibilità.

Output di alta qualità

Il nostro processo di lavaggio e purificazione multistadio rimuove meticolosamente contaminanti come sporco, etichette e adesivi, producendo fiocchi puliti e uniformi adatti a un'ampia gamma di applicazioni di produzione.

Efficienza automatizzata

Progettato per garantire elevata produttività e affidabilità, il nostro processo semplificato, dalla triturazione all'essiccazione, è completamente automatizzato per ridurre al minimo i tempi di fermo, diminuire i costi di manodopera e massimizzare la produttività operativa.

Vantaggio economico e ambientale

Trasforma un rifiuto in una risorsa preziosa. Produci scaglie riciclate a basso costo che riducono la domanda di plastica vergine, preservano le risorse naturali e riducono significativamente l'impronta di carbonio.

Dai rifiuti ingombranti ai fiocchi puliti: il processo

Riduzione delle dimensioni

Le plastiche rigide e voluminose vengono inserite in un potente trituratore e granulatore, che le riduce in piccoli fiocchi uniformi.

Lavaggio e separazione

I fiocchi vengono sottoposti a un'intensa pulizia in lavatrici a frizione e purificati in vasche di flottazione per rimuovere i contaminanti.

Asciugatura

Una macchina disidratatrice e un essiccatore termico lavorano in tandem per rimuovere l'umidità, raggiungendo un livello di umidità finale ideale per la conservazione o la vendita.

Collezione

I fiocchi puliti e asciutti vengono raccolti in un silo di stoccaggio, spesso dotato di un sistema di rimozione della polvere, pronti per essere confezionati e riutilizzati.

Moduli chiave della linea di riciclaggio

Le nostre linee di riciclaggio sono modulari e possono essere personalizzate in base ai vostri specifici materiali in ingresso e alle vostre esigenze di uscita. Una tipica linea ad alte prestazioni include:

Riduzione primaria delle dimensioni

Un robusto trituratore monoalbero seguito da un frantoio (granulatore) riduce in modo efficiente i materiali voluminosi in scaglie uniformi, preparandoli per il processo di lavaggio. I nostri trituratori sono dotati di ampie camere di macinazione e cilindri idraulici veloci per la massima produttività.

Sistema di lavaggio intensivo

Una lavatrice a frizione ad alta velocità rimuove i residui di sporco e di superficie. Per i materiali più sporchi, è possibile integrare un sistema di lavaggio a caldo opzionale per eliminare contaminanti ostinati come olio e colla.

Sistema di purificazione

Un serbatoio flottante sfrutta la densità dell'acqua per eseguire una fase di separazione critica. Permette ai preziosi fiocchi di HDPE/PP di galleggiare, mentre i contaminanti più pesanti (PET, PVC, metallo, vetro) affondano e vengono rimossi dal sistema.

Sistema di asciugatura ad alta efficienza

Una macchina centrifuga per la disidratazione rimuove meccanicamente la maggior parte dell'acqua superficiale. Un successivo sistema di essiccazione termica a tubi utilizza aria calda per ridurre il contenuto di umidità finale a meno di 1%, garantendo che i fiocchi siano pronti per la pellettizzazione o la produzione di alta qualità.

Specifiche tecniche e consumi

| Opzioni di capacità | da 500 kg/ora a 2000 kg/ora |

|---|---|

| Materiali applicabili | HDPE, PP (bottiglie, casse, tubi, fusti, ecc.) |

| Prodotto finale | Scaglie di plastica pulite e ad alta purezza |

| Contenuto di umidità finale | < 1% |

| Sistema di controllo | PLC automatizzato con HMI |

| Elettricità | ~ 50 - 80 kWh / Ton |

|---|---|

| Acqua | ~ 0,8 - 1,5 tonnellate / tonnellata (standard di ricircolo) |

| Aria compressa | ~ 0,5 - 1 m³ / Tonnellata |

| Detersivo (facoltativo) | ~ 2 - 4 kg / tonnellata |

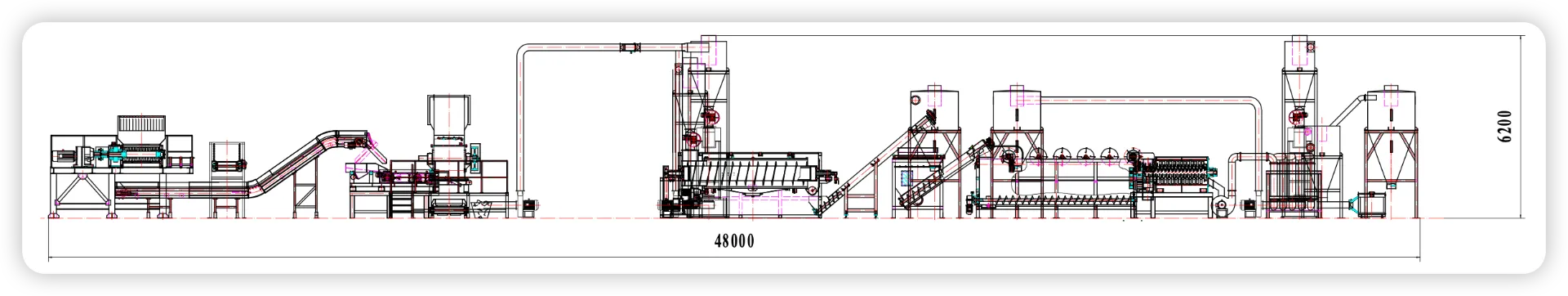

Diagramma di layout del sistema

Domande frequenti

Qual è la qualità dei fiocchi di plastica riciclata finali?

Il nostro sistema è progettato per produrre scaglie ad elevata purezza. Con un'adeguata selezione e il sistema opzionale di lavaggio a caldo, il prodotto finale può raggiungere un livello qualitativo idoneo alla produzione di nuovi tubi, contenitori, componenti per autoveicoli e altro ancora, spesso rivaleggiando con i materiali vergini in determinate applicazioni.

Quanta acqua consuma la linea di riciclaggio?

Sebbene il lavaggio richieda acqua, le nostre linee sono progettate pensando all'efficienza. Tutti i nostri sistemi integrano il ricircolo e la filtrazione dell'acqua, riducendo significativamente il consumo di acqua dolce a circa 0,8-1,5 tonnellate per tonnellata di plastica lavorata.

Questa linea può essere personalizzata in base alle mie esigenze specifiche?

Assolutamente sì. Le nostre linee sono completamente modulari. Possiamo regolare la capacità (da 500 a 2000 kg/ora), aggiungere o rimuovere moduli specifici (come il lavaggio a caldo o una seconda vasca di flottazione) e configurare il layout in base allo spazio del vostro impianto e al livello di contaminazione del materiale.

Collabora con noi per le tue esigenze di riciclaggio

Tutte le nostre macchine per il riciclaggio sono coperte da una garanzia limitata completa di 1 anno. Contattaci oggi stesso per discutere del tuo progetto, ottenere un preventivo aggiornato e ricevere un layout personalizzato per la tua attività.