Notizie sul riciclaggio

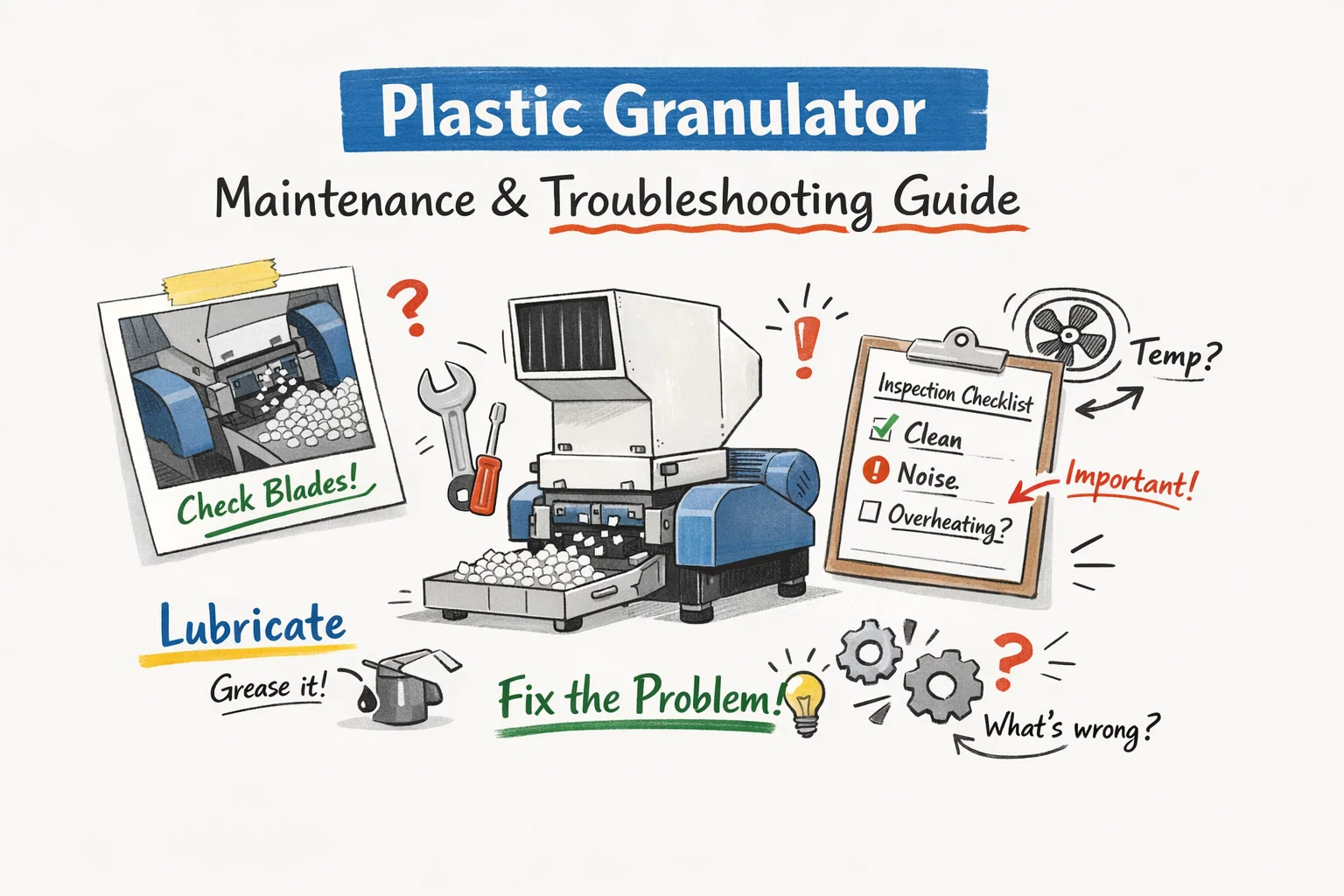

Granulatori di plastica Sono una parte fondamentale delle operazioni quotidiane negli impianti di riciclaggio, responsabili della riduzione dei rifiuti plastici in granuli uniformi per la lavorazione successiva. Nel tempo, tuttavia, usura, contaminazione e funzionamento improprio possono ridurre significativamente le prestazioni e aumentare i tempi di fermo.

Questa guida si concentra su manutenzione pratica, risoluzione dei problemi e migliori pratiche operative per aiutare gli impianti di riciclaggio a prolungare la durata di vita, mantenere una produzione stabile e ridurre gli arresti non pianificati, senza sovrapposizioni con le decisioni di selezione o acquisto delle apparecchiature.

Perché la corretta manutenzione del granulatore è importante negli impianti di riciclaggio

Nelle operazioni di riciclo continuo, un granulatore di plastica è esposto a materiali variabili, contaminanti abrasivi e carichi meccanici elevati. Senza una routine di manutenzione strutturata, anche le macchine ben progettate possono subire un'usura prematura e un calo delle prestazioni.

Una manutenzione efficace aiuta a:

- Mantenere una qualità costante dei granuli durante lunghe tirature di produzione

- Ridurre le fermate impreviste e le riparazioni di emergenza

- Prolungare la durata operativa dei componenti soggetti a usura

- Migliorare l'efficienza e la sicurezza complessiva dell'impianto

Per gli impianti di riciclaggio che operano con margini ridotti, la manutenzione preventiva è spesso più conveniente delle riparazioni reattive.

Attività essenziali di manutenzione del granulatore di plastica

Un programma di manutenzione strutturato garantisce un funzionamento stabile in condizioni di riciclaggio reali. Le seguenti attività sono consigliate per la maggior parte degli ambienti di riciclaggio industriale.

Manutenzione giornaliera

- Pulire la tramoggia e l'area di alimentazione per evitare l'accumulo di materiale

- Ispezionare la camera di taglio per verificare la presenza di residui di plastica o contaminazione

- Controllare le lame e gli schermi per individuare eventuali segni di usura

- Verificare i punti di lubrificazione in base alle ore di funzionamento e al carico

Manutenzione settimanale

- Filtri dell'aria puliti per mantenere un raffreddamento e un flusso d'aria adeguati

- Controllare le cinghie di trasmissione e gli accoppiamenti per verificarne la tensione e l'allineamento

- Controllare i collegamenti elettrici per verificare che non siano allentati o surriscaldati

- Rimuovere l'accumulo di polvere dalle superfici esterne

Manutenzione mensile

- Verificare l'allineamento del rotore e dello statore in condizioni operative

- Ispezionare i cuscinetti per rilevare rumori anomali o aumento della temperatura

- Pulire e lubrificare il cambio, se applicabile

- Testare i sistemi di sicurezza come arresti di emergenza e interblocchi

Revisione annuale o programmata

- Sostituire i componenti soggetti a usura elevata come lame, schermi e cuscinetti

- Ispezionare gli elementi strutturali per verificare la presenza di fatica o crepe

- Ricontrollare la calibrazione della macchina per ripristinare l'efficienza di taglio

- Esaminare i registri operativi per identificare problemi ricorrenti

Risoluzione dei problemi comuni del granulatore di plastica

Anche con una manutenzione regolare, possono comunque verificarsi problemi operativi. Una diagnosi precoce può impedire che piccoli problemi si aggravino.

Il granulatore non si avvia

- Confermare l'alimentazione stabile e la tensione corretta

- Ispezionare gli interruttori di sicurezza e gli interblocchi

- Assicurarsi che il circuito di arresto di emergenza sia completamente ripristinato

Produzione o rendimento ridotti

- Controllare l'affilatura della lama e lo spazio di taglio

- Ispezionare gli schermi per eventuali intasamenti o deformazioni

- Verificare che le dimensioni del materiale di alimentazione e la portata siano coerenti

Granuli di dimensioni incoerenti

- Ispezionare le lame e gli schermi per verificare l'usura irregolare

- Confermare il corretto allineamento rotore-statore

- Valutare la consistenza del materiale di input e i livelli di contaminazione

Rumore o vibrazioni eccessivi

- Ispezionare i cuscinetti e i punti di montaggio

- Controllare lo squilibrio del rotore causato da un'usura non uniforme

- Assicurarsi che la macchina sia correttamente livellata e ancorata

Migliori pratiche operative per migliorare le prestazioni del granulatore

Oltre alla manutenzione ordinaria, la disciplina operativa gioca un ruolo fondamentale nelle prestazioni a lungo termine.

Utilizzare lame e schermi adatti all'applicazione

La scelta di componenti di taglio adatti al tipo di materiale, allo spessore e alla durezza riduce il consumo di energia e l'usura.

Mantenere un processo di alimentazione stabile

Sovratensioni improvvise o un'alimentazione non uniforme aumentano lo stress meccanico e accelerano il degrado della lama.

Monitorare le tendenze del consumo energetico

Un aumento graduale dell'assorbimento di potenza spesso indica usura della lama, ostruzione dello schermo o problemi ai cuscinetti prima che si manifestino sintomi visibili.

Applicare la manutenzione predittiva ove possibile

Il monitoraggio delle condizioni, l'analisi delle vibrazioni e il monitoraggio della temperatura aiutano a individuare tempestivamente i guasti e a ridurre i tempi di fermo non pianificati.

Quando la sola manutenzione non è più sufficiente

La manutenzione può prolungare la durata utile, ma non può compensare indefinitamente le limitazioni di capacità, l'affaticamento strutturale o i cambiamenti dei requisiti di produzione.

Se un impianto di riciclaggio subisce:

- Calo persistente della produttività

- Vibrazioni in aumento nonostante le ripetute riparazioni

- Usura strutturale che influisce sulla sicurezza o sull'affidabilità

potrebbe essere il momento di valutare sostituzione delle apparecchiature o aggiornamenti del sistema.

Per le strutture che stanno valutando nuove soluzioni, potete consultare qui le nostre opzioni per granulatori industriali di plastica:

https://www.energycle.com/plastic-granulators/

(Riferimento unico a fini di valutazione; le linee guida per la manutenzione restano indipendenti dall'apparecchiatura.)

Conclusione

La manutenzione dei granulatori di plastica non è una semplice checklist: è una strategia operativa che influisce direttamente sulla produttività, sulla sicurezza e sul controllo dei costi negli impianti di riciclaggio. Combinando manutenzione preventiva, risoluzione dei problemi strutturata e gestione disciplinata, gli operatori del settore del riciclaggio possono ottenere prestazioni più affidabili e una maggiore durata delle apparecchiature.

Una netta separazione tra guida operativa E selezione dell'attrezzatura garantisce un processo decisionale migliore in ogni fase del processo di riciclaggio.

Domande frequenti (FAQ)

Con quale frequenza è necessario sottoporre a manutenzione le lame del granulatore?

Gli intervalli di manutenzione dipendono dall'abrasività del materiale, dal livello di contaminazione e dalle ore di funzionamento. Negli ambienti di riciclaggio industriale, l'ispezione è comune ogni 100-300 ore.

I ricambi aftermarket sono adatti alle operazioni di riciclaggio?

Sebbene i ricambi aftermarket possano ridurre i costi a breve termine, la compatibilità e la durata possono variare. Ricambi non omogenei spesso portano a un'usura più rapida e a un funzionamento instabile.

Come dovrebbero essere formati gli operatori per la manutenzione quotidiana?

Gli operatori devono seguire una checklist documentata che includa pulizia, ispezione e verifica della sicurezza. Formazione pratica e supervisione sono essenziali per garantire la coerenza.

Cosa fare in caso di guasto improvviso?

Spegnere la macchina in modo sicuro, isolare l'alimentazione e diagnosticare sistematicamente il problema. Guasti ripetuti indicano solitamente problemi meccanici o operativi più profondi.

Nostro pressa a vite per film plastico I sistemi (spremitura/densificazione) sono destinati principalmente all'Europa e al Nord America, dove gli operatori del riciclaggio si trovano ad affrontare una realtà comune: costi di manodopera più elevati, requisiti di qualità più severi e prezzi dell'energia in aumento. Gli acquirenti in queste regioni in genere danno priorità ad apparecchiature in grado di offrire:

- Riduzione stabile dell'umidità per film lavato (per migliorare la stabilità dell'estrusione e la qualità del pellet)

- Costi operativi inferiori attraverso un'efficiente disidratazione e utilizzo del calore

- Rendimento costante con un intervento minimo dell'operatore

- Prestazioni affidabili su materie prime difficili (pellicola stampata, pellicola mista, pellicola bagnata o contaminata)

Europa (UE/Regno Unito): La domanda è più forte nei Paesi con infrastrutture di riciclo consolidate e obiettivi di riciclo degli imballaggi rigorosi, in particolare Germania, Italia, Francia, Spagna, Paesi Bassi, Polonia e Regno Unito. Questi mercati richiedono spesso un controllo più rigoroso della contaminazione e dell'umidità per soddisfare le aspettative di qualità dei pellet a valle.

Nord America (USA/Canada): Molti impianti stanno aumentando la capacità produttiva per processare più film post-consumo e film commerciali/industriali. Le priorità comuni includono automazione, tempi di attività e riduzione del consumo energetico per tonnellata, mantenendo al contempo una qualità costante dei pellet per applicazioni di valore più elevato.

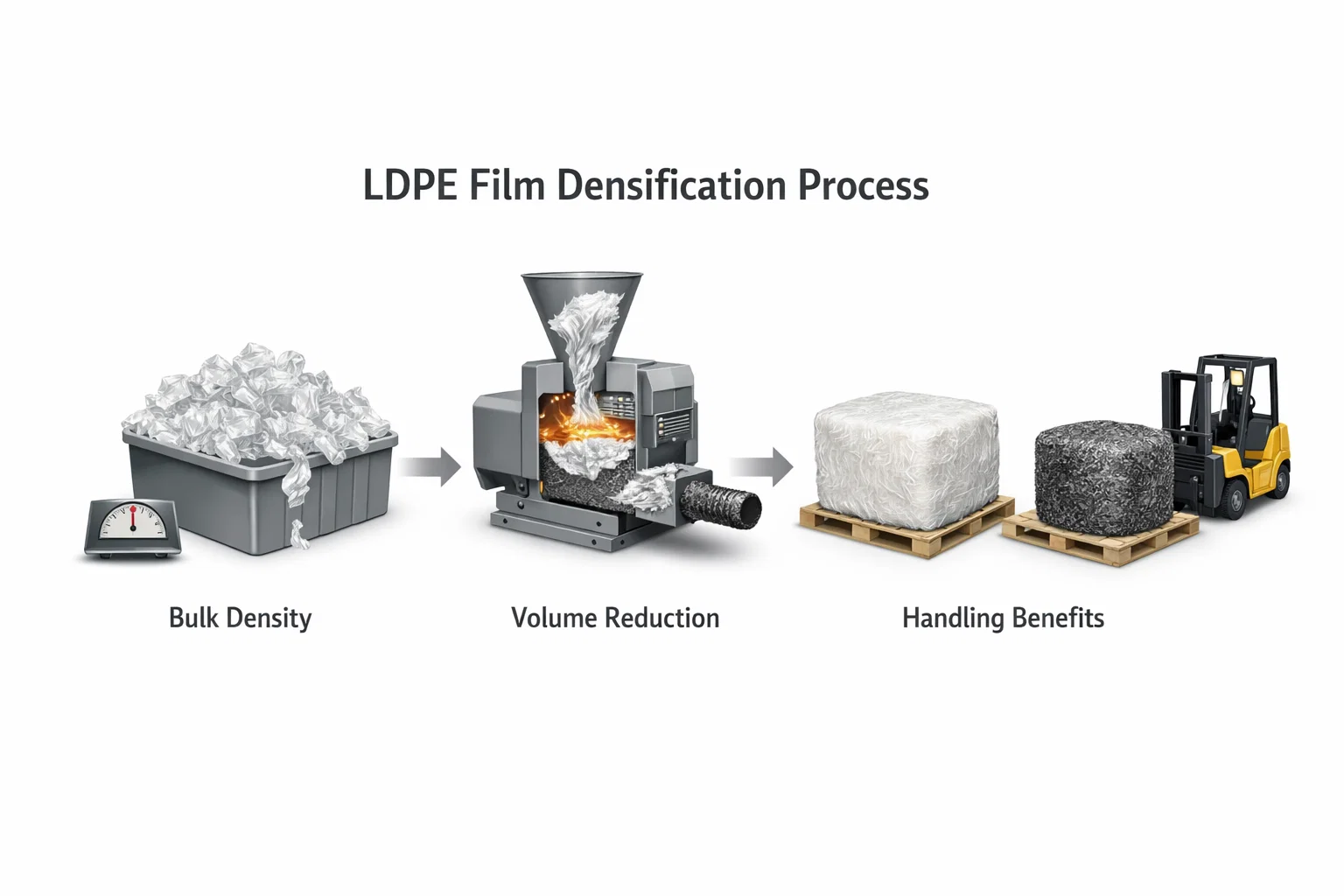

Che cos'è un sistema di pressatura a vite per film plastico (spremitura/densificazione)?

Un sistema di pressatura a vite per film plastico è un fase di disidratazione meccanica + densificazione utilizzato dopo una linea di lavaggio della pellicola. Rimuove l'acqua libera dalla pellicola lavata utilizzando compressione e taglio, convertendo la pellicola umida e soffice in un uscita calda, densificata e a bassa umidità che alimenta in modo più affidabile un estrusore e un pelletizzatore.

In una tipica linea di produzione di pellicole, la pressa a vite si trova dopo:

selezione → triturazione → lavaggio → (risciacquo per attrito/galleggiamento) → disidratazione meccanica → pressa a vite (spremitrice) → estrusione → pellettizzazione

Rispetto alle centrifughe di base o ai semplici rulli di compressione, una pressa a vite ben progettata può offrire:

- Umidità più bassa e più stabile

- Uscita calda e compatta (film densificato)

- Ridotto intrappolamento dell'aria prima dell'estrusione

- Migliore stabilità della linea in base alla variazione delle materie prime nel mondo reale

Perché il controllo dell'umidità ha un impatto diretto sui costi e sulla qualità dei pellet

L'umidità non è solo "acqua". Nel riciclaggio delle pellicole, i problemi di umidità sono spesso associati a:

- residui di detersivo, contaminanti fini e tracce organiche

- sostanze volatili dell'inchiostro (pellicola stampata)

- asciugatura non uniforme a causa della variazione dello spessore del film

- acqua intrappolata all'interno di pieghe e strutture multistrato

Se l'umidità è instabile, l'estrusore deve contrastarla. Il risultato è familiare a qualsiasi riciclatore di pellicole:

- bolle/vuoti nei pellet

- pressione di fusione instabile

- frequenti cambi dello schermo (contaminazione + gel)

- minore produttività o rallentamenti forzati

- maggiore consumo di energia per tonnellata

- più scarti e più interventi degli operatori

Una pressa a vite risolve il problema prima, prima che l'estrusore diventi un "essiccatore".“

Acquirenti principali: per chi è stato progettato questo sistema

Questo sistema è progettato per gli impianti che necessitano di trasformare film plastico lavato in materie prime stabili e di alta qualità per l'estrusione e la pellettizzazione. Tra i clienti tipici figurano:

1) Impianti di riciclaggio di pellicole plastiche (post-consumo e post-industriali)

- Operatori che elaborano Film LDPE/LLDPE, film estensibile, film per imballaggio, sacchetti per la spesa, film agricolo e materie plastiche flessibili miste

- Impianti che gestiscono una linea completa: selezione → triturazione → lavaggio → disidratazione/spremitura → estrusione → pellettizzazione

2) Impianti di pellettizzazione/granulazione

- I produttori passano dalla disidratazione di base a un migliore controllo dell'umidità per una maggiore stabilità della fusione

- Piante che mirano a maggiore consistenza del pellet, meno bolle/vuoti e odore ridotto causato dall'umidità residua e dalle sostanze volatili

3) Integratori di linee di lavaggio e costruttori di linee EPC/chiavi in mano

- Aziende di ingegneria e integratori che forniscono linee complete di riciclaggio di film e necessitano di una fase di spremitura/densificazione affidabile per ottimizzare il ROI dell'intero sistema

4) Gli operatori di gestione dei rifiuti e MRF si espandono nel riciclaggio dei film

- Gli operatori aggiungono la capacità di riciclaggio dei film per ottenere più valore dai flussi di imballaggi flessibili

5) Trasformatori e produttori di plastica con riciclo interno

- Fabbriche che recuperano internamente gli scarti di pellicola e cercano di ridurre i costi di smaltimento e migliorare l'efficienza di rielaborazione

Tipici decisori

In Europa e Nord America, le decisioni di acquisto sono solitamente guidate da:

- Proprietari di impianti / Direttori generali (ROI e capacità)

- Responsabili delle operazioni (tempo di attività, personale, stabilità)

- Ingegneri di processo (obiettivi di umidità, qualità del pellet, integrazione della linea)

- Responsabili della manutenzione (manutenibilità e parti soggette ad usura)

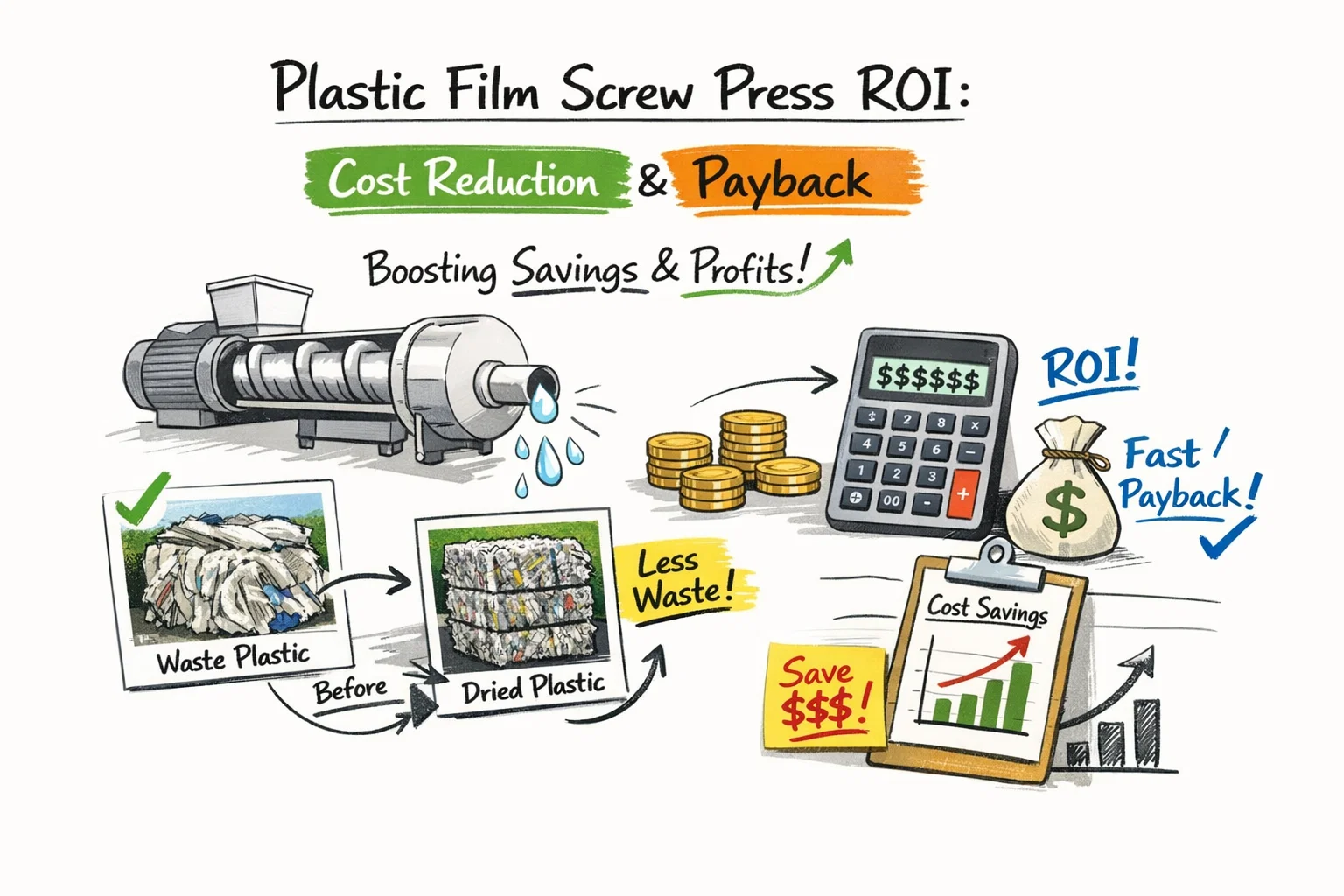

Riduzione dei costi: dove la pressa a vite offre un vero ROI

Quando le piante valutano un sistema di pressatura a vite, la domanda più importante non è "come funziona", ma dove si risparmiano i soldi. Nelle operazioni reali, i risparmi derivano in genere da cinque aree:

1) Maggiore produttività e minori rallentamenti

Il film bagnato si comporta in modo incoerente e può sovraccaricare gli alimentatori, causare ponti o forzare l'estrusore a funzionare a velocità inferiore. Una pressa a vite produce materiale denso, caldo, consistente, che migliora l'alimentazione e stabilizza l'estrusione.

Impatto pratico:

- pressione di fusione più stabile

- meno fermate di emergenza

- miglioramento del tempo di esecuzione per turno

- più facile mantenere l'output target

2) Minore consumo di energia per tonnellata

Se l'umidità entra nell'estrusore, l'energia viene spesa per:

- acqua evaporante

- compensare l'instabilità della fusione

- far funzionare i sistemi di vuoto più duramente (e più a lungo)

Rimuovendo l'acqua meccanicamente (metodo generalmente più economico rispetto alla rimozione termica), si riduce il carico energetico a valle.

Cosa migliora:

- kWh/tonnellata inferiori per l'estrusione

- meno shock termici e meno sbalzi di temperatura

- riduzione della domanda di riscaldamento grazie alla materia prima densificata più calda

3) Riduzione dei costi di manodopera attraverso interventi ridotti

Molte linee di produzione cinematografica si affidano all'abilità dell'operatore per "combattere la variabilità". Una pressa a vite riduce la variabilità stessa.

Dove cala il lavoro:

- meno regolazioni agli alimentatori e alle impostazioni dell'estrusore

- meno arresti per la pulizia e la risoluzione dei problemi

- meno tempo impiegato nella gestione di pellicole umide e soffici (disintasamento manuale, pulizia dei ponti, ecc.)

4) Migliore qualità del pellet (prezzo di vendita più alto o accesso più ampio agli acquirenti)

L'umidità e le sostanze volatili contribuiscono in modo significativo a:

- bolle nei pellet

- difetti legati all'odore e al vapore

- scarsa finitura superficiale

- comportamento instabile dell'MFI nell'elaborazione a valle

Un migliore controllo dell'umidità può consentire:

- aspetto del pellet più uniforme

- meno reclami/resi dei clienti

- accesso ad applicazioni di valore più elevato (a seconda della materia prima e della progettazione complessiva della linea)

5) Riduzione di scarti, tempi di fermo e stress da manutenzione

L'alimentazione umida instabile spesso aumenta:

- frequenza di caricamento e modifica del pacchetto schermo

- contaminazione da riporto

- usura di viti, riscaldatori e componenti a valle

- “tempi di inattività nascosti” dovuti a continui micro-arresti e cicli di riavvio

Un'alimentazione densificata stabile riduce lo stress operativo lungo tutta la linea.

Analisi del ROI: come calcolare il ritorno sull'investimento in un impianto di riciclaggio di film

Un modello di ROI semplice e pratico comprende quattro elementi misurabili:

- Produzione extra (tonnellate/anno) da tempi di attività migliorati e produttività stabile

- Risparmio energetico (kWh/tonnellata o $/tonnellata) da un carico di essiccazione inferiore e da un'estrusione stabile

- Risparmio di manodopera ($/anno) da interventi ridotti e meno fermate

- Miglioramento della qualità ($/tonnellata) se i pellet migliorati raggiungono prezzi migliori o una più ampia accettazione da parte dei clienti

Formula ROI (semplificata)

Beneficio annuo = (tonnellate extra × margine per tonnellata) + risparmio energetico + risparmio di manodopera + miglioramento della qualità

Periodo di ammortamento = Investimento del sistema / Beneficio annuo

Nota: il “margine per tonnellata” dovrebbe essere il margine reale (prezzo di vendita meno costi variabili), non il fatturato.

Esempio di scenario ROI (illustrativo)

Per chiarire i calcoli, ecco un illustrativo esempio (i numeri variano a seconda della pianta e della regione):

Condizioni della pianta:

- Linea di produzione di film lavato da 3.000 a 6.000 tonnellate/anno

- Le attuali fluttuazioni di umidità causano frequenti rallentamenti e problemi di qualità

Ipotesi di miglioramento conservative dopo l'aggiornamento della pressa a vite:

- +8% miglioramento effettivo del tempo di attività/rendimento

- -10% consumo energetico di estrusione per tonnellata

- -1 ora/giorno di intervento in meno per operatore (o riduzione equivalente dei costi)

- riduzione di scarti e rilavorazioni

Anche con ipotesi conservative, molti impianti prevedono un ritorno dell'investimento determinato da:

- maggiore produzione vendibile (tonnellate)

- meno fermate

- costo operativo totale inferiore per tonnellata

Se vuoi, possiamo costruire un foglio ROI personalizzato utilizzando i tuoi numeri effettivi (capacità, tariffa kWh, tariffa manodopera e tasso di scarto) in modo che la stima del ritorno sull'investimento corrisponda al mercato di riferimento del tuo sito.

Obiettivi chiave di prestazione richiesti dagli acquirenti

Quando gli acquirenti nell'UE/Regno Unito e nel Nord America valutano i sistemi di pressatura a vite, solitamente chiedono:

- Consistenza dell'umidità (non solo l'umidità media)

- Stabilità della produttività sotto pellicola mista e pellicola stampata

- Costo delle parti soggette a usura e intervalli di sostituzione

- Facilità di pulizia e accesso per la manutenzione

- Compatibilità di integrazione con linee di lavaggio ed estrusione esistenti

- Funzionalità di automazione (controllo del carico, protezione di coppia, logica di allarme)

Come il sistema si integra in una linea di lavaggio e pellettizzazione

Un sistema di pressatura a vite è più efficace quando è integrato come parte di un flusso stabile:

- Mangime stabile dalla corda per stendere (lavaggio costante e disidratazione meccanica a monte)

- Disidratazione e densificazione con pressa a vite (rimozione meccanica dell'acqua e compattazione)

- Scarico controllato (uscita densa e calda direttamente al sistema di alimentazione dell'estrusore)

- Estrusione ottimizzata per la qualità della fusione, non costretto a fungere da asciugatrice

In molti aggiornamenti, la pressa a vite diventa lo "stabilizzatore" che consente all'estrusore di funzionare più vicino alla sua capacità progettata.

Domande frequenti (FAQ)

D1: La pressa a vite è in grado di gestire pellicole stampate e miste?

SÌ. I film stampati e i film misti contengono in genere più sostanze volatili e variazioni. La pressa a vite contribuisce a stabilizzare l'umidità e la densità di alimentazione, riducendo gli shock di processo a valle.

D2: Sostituisce l'asciugatrice?

In molte linee di produzione cinematografica, la pressa a vite riduce o semplifica Esigenze di essiccazione. La sostituzione completa dell'essiccazione termica dipende da:

- il tuo obiettivo di umidità per l'estrusione

- il tipo di materia prima e la contaminazione

- il tuo design generale della linea

D3: È difficile da usare per gli operatori?

No. La maggior parte dei sistemi è progettata per un funzionamento semplice con:

- controllo del carico e protezione della coppia

- cancellare allarmi e interblocchi

- uscita stabile che riduce l'intervento manuale

D4: Cosa conta di più per il ROI: la riduzione dell'umidità o la densificazione?

Entrambi gli aspetti sono importanti. La riduzione dell'umidità migliora la stabilità del fuso, mentre la densificazione migliora l'alimentazione e la produttività. Il miglior ritorno sull'investimento deriva solitamente dalla combinazione di:

- umidità stabile + densità di alimentazione stabile + meno fermate

Pronti a ridurre i costi e migliorare la stabilità dei pellet?

Se il tuo impianto sta elaborando pellicole lavate e stai combattendo:

- estrusione instabile

- bolle/vuoti

- tempi di inattività dall'alimentazione umida

- elevati costi operativi per tonnellata

Un sistema di pressatura a vite per film plastico è spesso uno dei modi più rapidi per migliorare il ROI perché stabilizza la fase a valle più costosa: estrusione e pellettizzazione.

Contattaci in base al tipo di materiale (LDPE/LLDPE/film misto), alla capacità desiderata e all'intervallo di umidità attuale. Possiamo consigliarti la configurazione più adatta e aiutarti a stimare il ROI in base ai costi di elettricità e manodopera della tua zona.

Questa guida rivolta all'acquirente spiega quando non si dovrebbe utilizzare un frantumatore di plastica, come scegliere tra un frantumatore e un trituratore in base alla lunghezza del materiale, alle soglie di capacità realistiche e quali opzioni "per impieghi gravosi" sono spesso inutili.

Pensato per i professionisti del riciclaggio, questo articolo ti aiuta a evitare errori costosi e a scegliere la soluzione di riduzione delle dimensioni più adatta alla tua linea di riciclaggio.

Questo articolo illustra i sette principali tipi di plastica, quali materiali vengono comunemente riciclati, a cosa servono le plastiche riciclate e le attrezzature tipiche necessarie per ogni processo di riciclo. Una guida pratica e ingegneristica per riciclatori, gestori di impianti e sviluppatori di progetti.

Questo articolo illustra le principali applicazioni dei fiocchi di PET, i gradi di qualità più comuni e gli indicatori tecnici che ne determinano il valore, dalle fibre e dai fogli al riciclo bottiglia-bottiglia. Ideale per proprietari di impianti di riciclo, acquirenti di attrezzature e investitori di progetti.