Comprehensive Maintenance Plan for Trommel Screens

Trommel screens are widely used in material separation across various industries, including mining, waste processing, and recycling. These machines handle large volumes of materials and are subject to wear and tear, making regular maintenance critical to ensure their smooth operation and extend their lifespan.

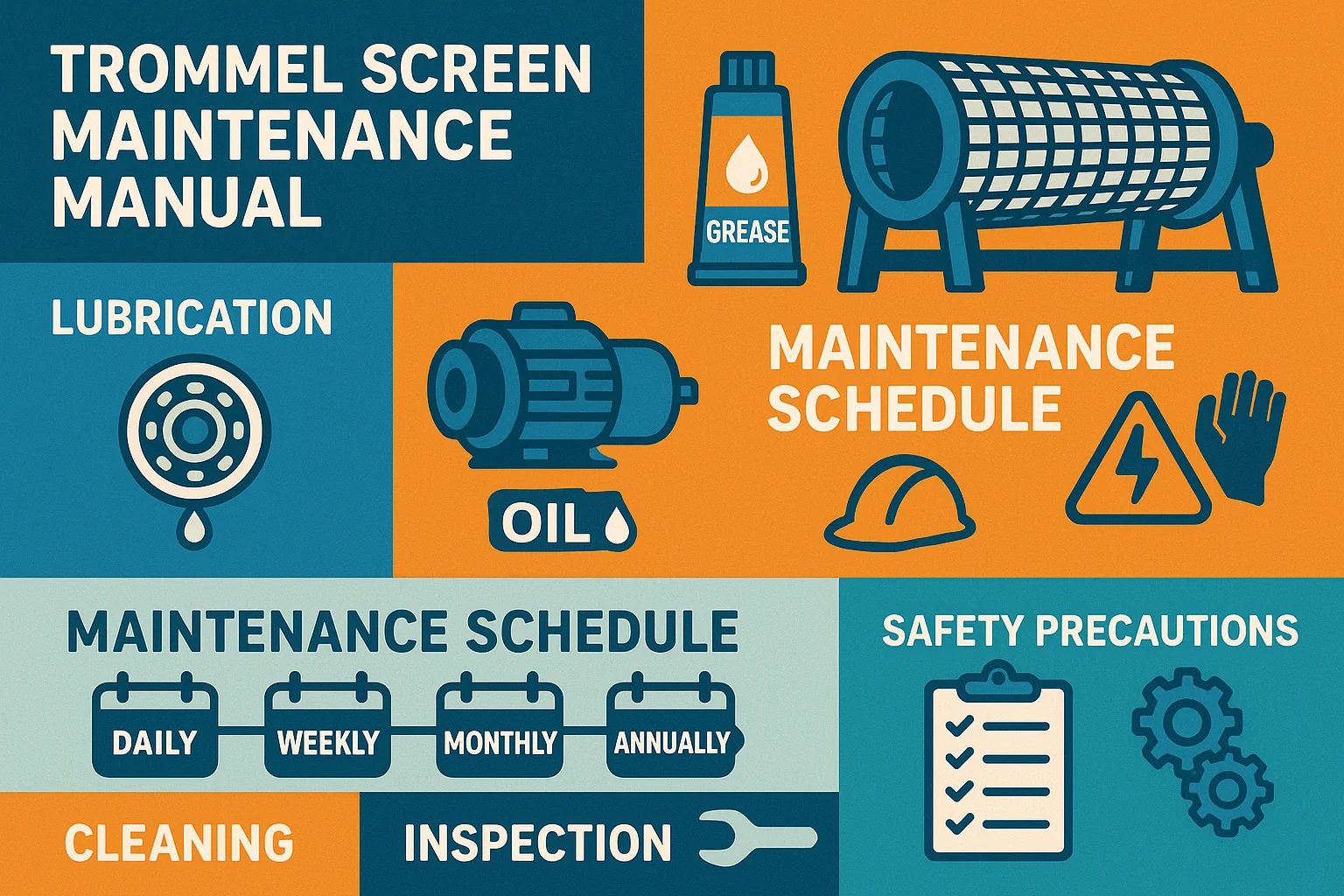

Key Maintenance Benefits: Regular maintenance maintains operational efficiency, minimizes downtime, and avoids costly repairs through proper lubrication and scheduled servicing.

1. Maintenance Plan for Trommel Screens

A. Lubrication and Grease Requirements

Cuscinetti: The most critical components requiring regular lubrication

- Grease Type: Calcium-based grease (water-resistant for moist environments)

- Frequency: Every 40-50 working hours or daily in heavy use

Gearbox/Reducer: Power transmission system

- Oil Type: 220# heavy-duty gear oil

- Frequency: Top-up monthly; full change every 1,000 hours

Motore: Core power component

- Grease Type: NLGI No. 2 multi-purpose bearing grease

- Frequency: Every 200 hours or during major servicing

B. Lubricating Oil Specifications

- Use ISO 46 or ISO 68 hydraulic oil (temperature-dependent)

- Check levels daily; replace every 2,000 hours

- Use high-performance, non-corrosive oil

- Clean/replace filters per manufacturer schedule

2. Regular Maintenance Schedule

- Lubricate all bearing points

- Check hydraulic oil levels

- Clean drum and screen surfaces

- Grease conveyor system bearings

- Inspect/clean drum screens

- Service air filters

- Inspect hydraulic hoses/connections

- Service hydraulic return filters

- Check belt tension

- Replace all filters (air/oil/fuel)

- Change engine and gearbox oil

- Structural wear inspection

- Full gearbox oil replacement

- Engine belt inspection

- Hydraulic system flush

⚠️ Critical Safety Reminder

Always perform maintenance with equipment powered off and properly secured. Never service moving components, and ensure all safety guards are reinstalled before operation.

3. Longevity Enhancement Tips

- Implement dust control systems to reduce abrasive wear

- Monitor vibration levels for early imbalance detection

- Adhere to material specifications to prevent overloading

- Maintain detailed service records for predictive maintenance

Conclusione

This comprehensive maintenance plan, when properly implemented, will maximize your trommel screen’s operational efficiency and service life. Always cross-reference with your specific equipment manual and adjust frequencies based on actual operating conditions and manufacturer recommendations.

Pro Tip: Consider implementing a digital maintenance tracking system to automate service reminders and documentation.