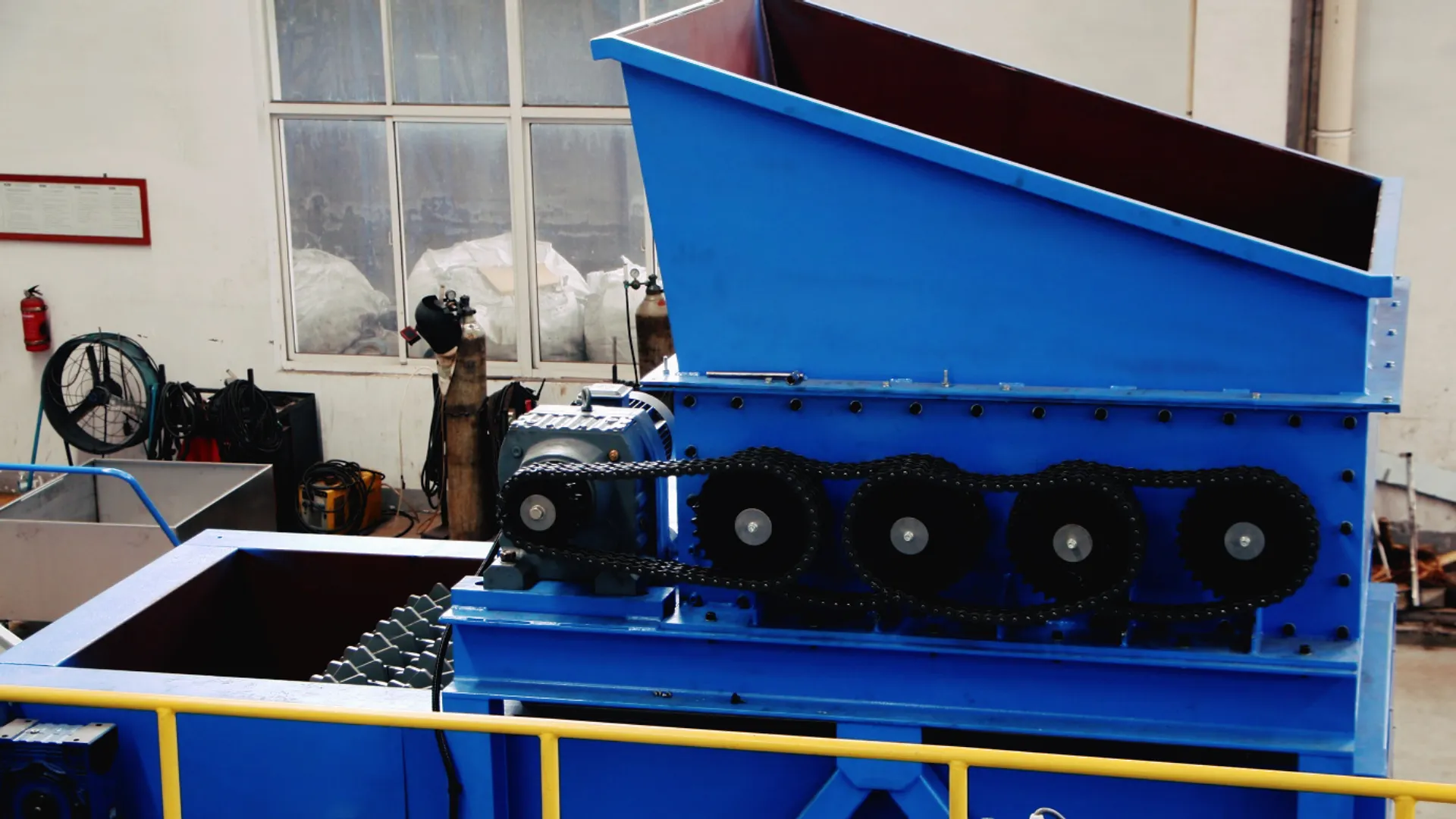

In the world of PET 병 재활용, the debaler machine is an indispensable piece of equipment. The first step in any PET bottle recycling process involves handling the bales of compacted plastic bottles that arrive at the facility. These bales, tied together by metal wire, need to be carefully opened to allow the bottles to flow freely onto a conveyor belt, where they can proceed to the next stage of the recycling process, such as label removal or crushing. This is where the debaler machine plays a crucial role.

How a Debaler Machine Works

The function of a debaler machine is straightforward yet essential. Instead of manually opening PET bottle bales—a process that can be labor-intensive and time-consuming—the debaler automates this task, significantly improving operational efficiency.

For facilities in countries where manual labor is expensive, the debaler machine is a cost-effective solution. It opens entire bales of PET bottles using slow-moving hooks designed to grapple onto the wires binding the bales. This allows entire bales of plastic bottles to be dropped directly into the debaler’s vertical feeder, typically using a forklift or similar equipment. The machine then efficiently unties the bales, allowing the bottles to proceed further along the recycling line.

Key Models & Specifications

When choosing a debaler machine, it’s essential to consider its specifications to ensure it meets your facility’s needs. Here are the standard specifications for our debaler machines:

- Feeder Dimensions: 1450mm x 1650mm

- Main Motor Power: 5.5kW

- Conveyor Motor Power: 7.5 KW

These specifications ensure the debaler can handle large volumes of PET bottles efficiently, making it an ideal first step in a PET bottle washing line.

추가 이미지

Placing an Order

If you’re ready to streamline your PET bottle recycling process, placing an order for a debaler machine is straightforward. The general lead time for single-piece, standard equipment orders is 30 days. However, for custom orders or complete washing lines, the lead time can range between 60 to 90 days, depending on the complexity of the project and the current production queue.

문의하기

For pricing and further ordering details, feel free to reach out to us. We’re here to help you select the right debaler machine for your needs and guide you through the ordering process.