Dissolved Air Flotation (DAF) systems are a crucial component in modern plastic recycling operations, offering a highly efficient and economical solution for wastewater treatment. By effectively removing contaminants such as total suspended solids (TSS), oils and grease (FOG), fats, and biochemical oxygen demand (BOD) from wastewater streams, DAF systems help make recycling processes more sustainable and cost-effective.

What is Dissolved Air Flotation (DAF)?

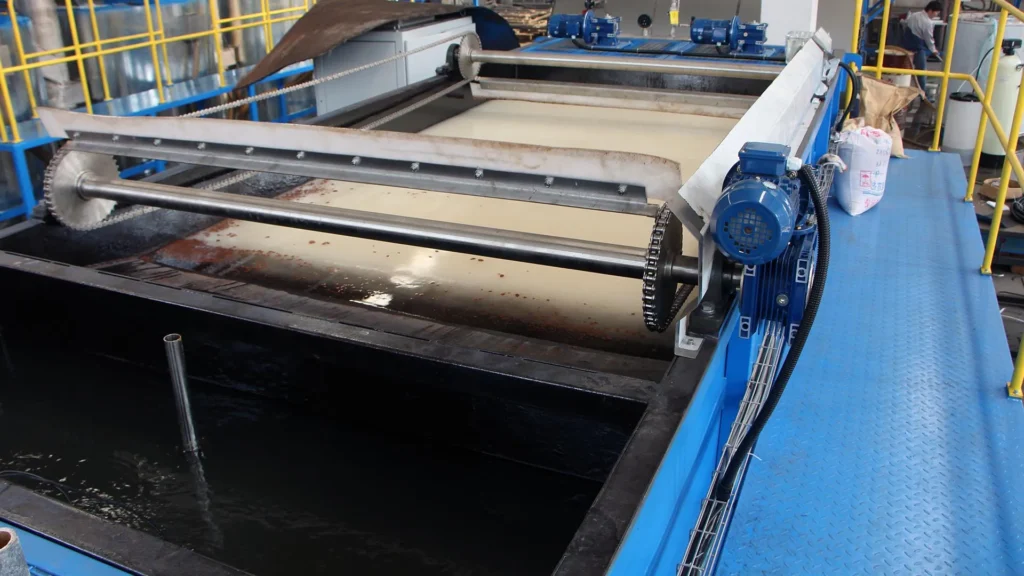

Dissolved Air Flotation (DAF) is a water treatment process that clarifies wastewater by removing suspended matter such as oils, solids, and other contaminants. This is achieved by dissolving air into the water under pressure, then releasing it at atmospheric pressure in a flotation tank. The released air forms tiny bubbles that attach to the suspended particles, causing them to float to the surface. These floated materials are then skimmed off, leaving the treated water clear and free of pollutants.

Why Use DAF in Plastic Recycling?

Plastic recycling plants generate significant amounts of wastewater contaminated with various substances, including microplastics, oils, and other chemical residues. Without proper treatment, this wastewater can harm the environment and lead to high disposal costs. Implementing a DAF system in plastic recycling plants not only addresses these environmental concerns but also reduces water consumption and operational costs.

Key Applications of DAF Systems

While DAF systems are particularly beneficial for plastic recycling, they are versatile and applicable in various industries, including:

- Paper Wastewater Treatment and Fiber Recovery: DAF helps in removing paper fibers and other suspended solids.

- Printing and Dyeing Wastewater Treatment: Effective in separating dyes and pigments.

- Electroplating Wastewater Treatment: Removes heavy metal ions.

- Oily Wastewater Treatment: Separates oils and grease from industrial effluents.

- Tannery Wastewater Treatment: Handles the removal of fats, hair, and chemicals.

- Chemical Wastewater Treatment: DAF systems are used for separating chemical contaminants.

- Food Wastewater Treatment: Ideal for treating fats, oils, and grease (FOG) in food industry effluents.

- Biological Treatment of Mud: DAF aids in the separation of biological sludge.

- Surface Water Treatment: Efficient in removing algae and other contaminants.

How DAF Works in Plastic Recycling

The working principle of a DAF system in plastic recycling involves a two-stage air compression process. Compressed air is dissolved into the wastewater, which is then released into a flotation tank. As the dissolved air is released, it forms microbubbles that attach to the suspended particles. These bubbles rise to the surface, where a mechanical scraper removes the contaminants, resulting in clarified water that can be reused in the recycling process.

To enhance the efficiency of this process, coagulants or flocculants such as Poly Aluminium Chloride (PAC) and Polyacrylamide (PAM) are often added. These chemicals help in aggregating the particles, making it easier for the microbubbles to lift them to the surface.

Technical Specifications of DAF Systems

The following table provides a quick reference to the technical specifications of various DAF models:

| 모델 | 모터 파워 | Pump Flow | 용량 |

|---|---|---|---|

| APW-5 | 2.2 kW | 10 m³/h | 5 m³/h |

| APW-10 | 4.0 kW | 12 m³/h | 10 m³/h |

| APW-20 | 4.0 kW | 16 m³/h | 20 m³/h |

| APW-30 | 5.5 kW | 22 m³/h | 30 m³/h |

CE certification is available, and larger, more powerful models can be custom-designed upon request.

Benefits of DAF Systems in Plastic Recycling

- 비용 효율성: By treating and recycling water on-site, DAF systems help reduce water consumption and lower operational costs.

- 환경적 지속 가능성: DAF systems minimize the discharge of pollutants into the environment, promoting eco-friendly practices in plastic recycling.

- Flexibility: These systems can be adapted to treat various types of wastewater, making them versatile across different industries.

- Improved Water Quality: The treated water can be reused within the recycling process, ensuring a continuous supply of clean water.

추가 이미지

결론

Implementing a Dissolved Air Flotation (DAF) system in your plastic recycling plant is an excellent step towards sustainability and cost savings. Not only does it ensure that your operations are environmentally responsible, but it also reduces the overall water bill by recycling and treating wastewater efficiently. With its wide range of applications, a DAF system is a valuable addition to any industry requiring wastewater treatment.

보증 및 설치

모든 재활용 기계에는 1년 제한 보증이 제공됩니다. 저희 엔지니어가 현장을 방문하여 설치 과정을 지원해 드리는 설치 서비스를 제공합니다. 정기적인 유지보수팀 및 운영 컨설턴트 지원도 가능합니다.

지금 문의하세요

최신 가격과 리드타임을 알아보려면 아래 양식을 사용하여 메시지를 보내주세요.